Abstract

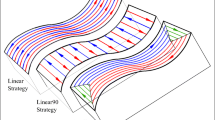

The task of milling hardened steel with complex-shaped surfaces (e.g., for dies and molds) differs from that of traditional milling. The tool is usually long with a small diameter, and therefore vibrates easily. Its trajectory must follow the surface shape, causing its effective diameter in contact with the workpiece to change as the cutter travels along the surface. Consequently, cutting speed also varies, which may affect tool life and surface roughness. Since the tool is not rigid, the tooth passing frequency, which is the main frequency of the cutting forces, may be close to the natural frequency of the tool, often leading to high vibration and even chatter. This study seeks to contribute to a better understanding and use of this type of process. Several experiments were performed, using tool overhang, lead angle, tooth passing frequency and feed direction as input variables. Three cutting force components and surface roughness were measured throughout the experiments, and the tool’s frequency response functions for the two tool overhang lengths used in the experiments were calculated to better analyze the results. The main conclusion was that feed direction was the input variable that most affected surface roughness, since the use of descendant milling led to lower variations in radial force, and hence, less vibration.

Similar content being viewed by others

References

Schützer K, Helleno AL, Pereira SC (2006) The influence of the manufacturing strategy on the production of molds and dies. J Mater Process Technol 179:172–177. doi:10.1016/j.jmatprotec.2006.03.098

Altan T, Lilly B, Yen YC (2001) Manufacturing of dies and molds. Ann CIRP 50:405–423. doi:10.1016/S0007-8506(07)62988-6

Vivancos J, Luis CJ, Costa L, Ortı́z JA (2004) Optimal machining parameters selection in high speed milling of hardened steels for injection moulds. J Mater Process Technol 155–156:1505–1512. doi:10.1016/j.jmatprotec.2004.04.260

Lamikiz A, López de Lacalle LN, Sánchez JA, Salgado MA (2004) Cutting force estimation in sculptured surface milling. Int J Mach Tool Manuf 44:1511–1526. doi:10.1016/j.ijmachtools.2004.05.004

Salgado MA, López de Lacalle LN, Lamikiz A, Muñoa J, Sánchez JA (2005) Evaluation of the stiffness chain on the deflection of end-mills under cutting forces. Int J Mach Tool Manuf 45:727–739. doi:10.1016/j.ijmachtools.2004.08.023

López de Lacalle LN, Lamikiz A, Sánchez JA, Salgado MA (2004) Effects of tool deflection in the high-speed milling of inclined surfaces. Int J Adv Manuf Technol 24:621–631. doi:10.1007/s00170-003-1723-x

Oliveira AJ, Diniz AE (2009) Tool life and tool wear in the semi-finish milling of inclined surfaces. J Mater Process Technol 209:5448–5455. doi:10.1016/j.jmatprotec.2009.04.022

Sun Y, Ren F, Guo D, Jia Z (2009) Estimation and experimental validation of cutting forces in ball-end milling of sculptured surfaces. Int J Mach Tool Manuf 49:1238–1244. doi:10.1016/j.ijmachtools.2009.07.015

Tuysuz O, Altintas Y, Feng HY (2013) Prediction of cutting forces in three and five-axis ball-end milling with tool indentation effect. Int J Mach Tool Manuf 66:66–81. doi:10.1016/j.ijmachtools.2012.12.002

Aguiar MM, Diniz AE, Pederiva R (2013) Correlating surface roughness, tool wear and tool vibration in the milling process of hardened steel using long slender tools. Int J Mach Tool Manuf 68:1–10. doi:10.1016/j.ijmachtools.2013.01.002

Kecelj B, Kopač J, Kampuš Z, Kuzman K (2004) Specialty of HSC in manufacturing of forging dies. J Mater Process Technol 157–158:536–542. doi:10.1016/j.jmatprotec.2004.07.112

Ozturk E, Tunc LT, Budak E (2009) Investigation of lead and tilt angle effects in 5-axis ball-end milling processes. Int J Mach Tool Manuf 49:1053–1062. doi:10.1016/j.ijmachtools.2009.07.013

Altintas Y, Budak E (1995) Analytical Prediction of Stability Lobes in Milling. CIRP Ann–Manuf Technol 44:357–362. doi:10.1016/S0007-8506(07)62342-7

Quintana G, Ciurana J (2011) Chatter in machining processes: A review. Int J Mach Tool Manuf 51:365–376. doi:10.1016/j.ijmachtools.2011.01.001

Coromant S (2000) Fabricacion de Moldes y Matrices. Guia de Aplicacion, Sandviken

Altintas Y (2000) Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design. Cambridge University Press, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kull Neto, H., Diniz, A.E. & Pederiva, R. Influence of tooth passing frequency, feed direction, and tool overhang on the surface roughness of curved surfaces of hardened steel. Int J Adv Manuf Technol 82, 753–764 (2016). https://doi.org/10.1007/s00170-015-7419-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7419-1