Abstract

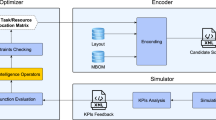

The proposed work addresses the problem of placing safety stock under the guaranteed-service model when a set of supplying, manufacturing and delivery stages model the production system. Every stage has a set of options that can perform the stage and every option has an associated cost and time. Hence, the problem is to select an option per stage that minimises the safety stock and lead time at the same time. We proposed solving the problem using two swarm intelligent meta-heuristics, Ant Colony and Intelligent Water Drop, because of their results in solving NP-hard problems such as the safety stock problem. In our proposed algorithm, swarms are created and each one selects an option per stage with its safety stock and lead time. After that, the Pareto Optimality Criterion is applied to all the configurations to compute a Pareto front. A real-life logistic network of the automotive industry is solved using our proposed algorithm. Finally, we provided some multi-objective performance metrics to assess the performance of our approach and carried out a statistical analysis to support our conclusions.

Similar content being viewed by others

References

Amini M, Li H (2011) Supply chain configuration for diffusion of new products: an integrated optimization approach. Omega 39(3):313–322

Bakker M, Riezebos J, Teunter RH (2012) Review of inventory systems with deterioration since 2001. Eur J Oper Res 221(2):275–284

Blum C, Merkle D (2008) Swarm intelligence: Introduction and applications. Springer

Bonabeau E, Dorigo M, Theraulaz G (1999) Swarm intelligence. Oxford

Chandra C., Grabis J. (2007) Supply chain configuration. Concepts, solutions and applications. Springer

Chopra S, Meindl P (2012) Supply chain management: Strategy, planning and operations, 5edn. Pearson Prentice Hall

Crowston WB, Wagner MH (1973) Dynamic lot size models for multi-stage assembly systems. Manag Sci 20(1):14–21

Dorigo M, Stützel T (2004) Ant Colony Optimization. MIT Press

Dorigo M, Stützle T (2010) Ant colony optimization: Overview and recent advances. In: Gendreau M, Potvin JY (eds) Handbook of Metaheuristics, International Series in Operations Research & Management Science, vol 146. Springer, pp 227–263

Duan H, Liu S, Wu J (2009) Novel intelligent water drops optimization approach to single UCAV smooth trajectory planning. Aerosp Sci Technol 13(8):442–449

Farahani RZ, Rezapour S, Drezner T, Fallah S (2014) Competitive supply chain network design: an overview of classifications, models, solution techniques and applications. Omega 45(0): 92–118

Goh M, Lim JYS, Meng F (2007) A stochastic model for risk management in global supply chain networks. Eur J Oper Res 182(1):164–173

Graves S, Willems S (2000) Optimizing strategic safety stock placement in supply chains. Manuf Serv Oper Manag 2(1):68–83

Graves S, Willems S (2005) Optimizing the supply chain configuration for new products. Manag Sci 51 (8):1165–1180

Huang G, Zhang X, Liang L (2005) Towards integrated optimal configuration of platform products, manufacturing processes, and supply chains. J Oper Manag 23(3-4):267–290

Lesnaia E, Vasilescu I, Graves S (2005) The Complexity of Safety Stock Placement in General-Network Supply Chains, Innovation in Manufacturing Systems and Technology (IMST)

Li H, Womer K (2008) Modeling the supply chain configuration problem with resource constraints. Int J Proj Manag 26(6):646–654

Moncayo-Martínez L, Resendiz-Flores E, Mercado D, Sanchez-Ramirez C (2014) Placing safety stock in logistic networks under guaranteed-service time inventory models: An application to the automotive industry. J Appl Res Technol 12(3):538–550

Moncayo-Martínez L, Zhang D (2013) Optimising safety stock placement and lead time in an assembly supply chain using bi-objective MAX–MIN ant system. Int J Prod Econ 141(1):18–28

Moncayo-Martínez LA, Recio G (2014) Bi-criterion optimisation for configuring an assembly supply chain using pareto ant colony meta-heuristic. J Manuf Syst 33(1):188–195

Moncayo-Martínez LA, Zhang DZ (2011) Multi-objective ant colony optimisation: a meta-heuristic approach to supply chain design. Int J Prod Econ 131(1):407–420

Nepal B, Monplaisir L, Famuyiwa O (2011) A multi-objective supply chain configuration model for new products. Int J Prod Res 49(23):7107–7134

Osman H, Demirli K (2012) Integrated safety stock optimization for multiple sourced stockpoints facing variable demand and lead time. Int J Prod Econ 135(1):299–307

Shah-Hosseini H (2007) Problem solving by intelligent water drops. In: IEEE congress on evolutionary computation , pp 3226–3231

Shah-Hosseini H (2008) Intelligent water drops algorithm: a new optimization method for solving the multiple knapsack problem. Int J Intell Comput Cybern 1(2):193–212

Shah-Hosseini H (2009) The intelligent water drops algorithm: a nature-inspired swarm-based optimization algorithm. Int J Bio-Inspired Comput 1(1/2):71–79

Snyder LV, Shen ZJM (2011) Fundamentals of supply chain theory. Wiley

Straub J (2013) Characterization of extended and simplified intelligent water drop (SIWD) approaches and their comparison to the intelligent water drop (IWD) approach. In: Proceedings of the 25th international conference on tools with artificial intelligence

Talbi EG (2009) Metaheuristics: From design to implementation, Wiley series on parallel and distributed computing. John Wiley & Sons

Wang F, Lai X, Shi N (2011) A multi-objective optimization for green supply chain network design. Decis Support Syst 51(2):262–269

Wang J, Shu Y (2007) A possibilistic decision model for new product supply chain design. Eur J Oper Res 177(2):1044–1061

Wilhelm W, Liang D, Rao B, Warrier D, Zhu X, Bulusu S (2005) Design of international assembly systems and their supply chains under NAFTA. Transp Res E: Logistics and Transportation Review 41(6):467–493

Xing B, Gao WJ (2014) Intelligent water drops algorithm. In: Innovative computational intelligence: a rough guide to 134 clever algorithms. Springer, pp 365–373

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moncayo–Martínez, L.A., Ramírez–López, A. & Recio, G. Managing inventory levels and time to market in assembly supply chains by swarm intelligence algorithms. Int J Adv Manuf Technol 82, 419–433 (2016). https://doi.org/10.1007/s00170-015-7313-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7313-x