Abstract

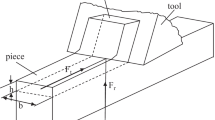

This paper presented a general model for predicting the cutting forces in oblique cutting operation with respect to vector transformation derived from orthogonal cutting process. The developed model is based on that the fundamental mechanics of the friction relationship between tool and material (chip) at the primary and secondary shear zones are the same when the flowing relationship between tool and chip is the same for the cutting processes with different inclination angles, including the orthogonal cutting process, in which inclination angle is 0. The cutting force loading on tool rake face in oblique cutting process with any inclination angle can be determined by the orthogonal cutting force data with the same tool-chip flowing relationship. To achieve precision orthogonal cutting force data, a mechanics model for orthogonal cutting process considering cutting speed, rake angle, and depth of cut is proposed and the predicting coefficients are calibrated by a set of turning tests. At last, a series of experiments under different cutting conditions are conducted to confirm the validity of the developed model. There is a good agreement between the experimental and simulative results, which shows the model is effective for cutting force prediction in orthogonal and oblique cutting operations.

Similar content being viewed by others

References

Merchant ME (1945) Mechanics of the metal cutting process I. Orthogonal cutting and a type 2 chip. J Appl Phys 16:267–275

Lee EH, Schaffer BW (1951) Theory of plasticity applied to a problem of machining. J Appl Mech 18:405–413

Piispanen V (1948) Theory of formation of metal chips. J Appl Phys 19:876–881. doi:10.1063/1.1697893

Oxley PLB, Welsh MJM (1963) Calculating the shear angle in orthogonal metal cutting from fundamental stress, strain, strain rate properties of the work material. In: Proc 4th Int. Mach. Tool Des. Res. Conf., Oxford, p 73-86

Fenton RG, Oxley PLB (1969) Mechanics of orthogonal machining-predicting chip geometry and cutting forces from work-material properties and cutting conditions. Proc Inst Mech Eng 184:927–942

Hastings WF, Mathew P, Oxley PLB (1980) Machining theory for prediction chip geometry, cutting forces etc from work material properties and cutting conditions. Proc R Soc Lond A Math Phys Sci 371(1747):569–587

Yang MY (1991) Prediction of cutting force in ball-end milling. Int J Mach Tools Manuf 31(1):45–54

Tai CC, Fuh KH (1995) Model for cutting forces prediction in ball-end milling. Int J Mach Tools Manuf 35(4):511–534

Li SJ, Zhou YF, Jin RC, Ji Z (2001) Dynamic force modeling for a ball-end milling cutter based on the merchant oblique cutting theory. Int J Adv Manuf Technol 17(7):477–483

Armarego EJA (1983) Practical implications of classical thin shear zone cutting analyses. UNESCO/CIRP Seminar on Manufacturing Technology, p 167-182, Singapore

Armarego EJA, Whitfield RC (1985) Computer based modelling of popular machining operations for force and power predictions. Annals CIRP 34:65–69

Armarego EJA, Smith AJR, Gong ZJ (1990) Four plane facet point drills-basic design and cutting model predictions. Annals CIRP 39(1):41–45

Armarego EJA, Deshpande NP (1993) Force prediction models and CAD/CAM software for helical tooth milling processes, part I, basic approach and cutting analyses. Int J Prod Res 31(8):1991–2009

Armarego EJA, Deshpande NP (1993) Force prediction models and CAD/CAM software for helical tooth milling processes, part II, peripheral milling operations. Int J Prod Res 31(10):2319–2336

Armarego EJA, Deshpande NP (1994) Force prediction models and CAD/CAM software for helical tooth milling processes, part III, end milling and slotting operations. Int J Prod Res 32(7):1715–1738

Armarego EJA, Uthaichaya M (1977) A mechanics of cutting approach for force prediction in turning operations. J Eng Prod 1(1):1–18

Budak E, Altintas Y, Armarego EJA (1996) Prediction of milling force coefficients from orthogonal cutting data. J Manuf Sci Eng 118(2):216–224

Kaymakci M, Kilic ZM, Altintas Y (2012) Unified cutting force model for turning, boring, drilling and milling operations. Int J Mach Tools Manuf 54–55:34–45

Altintas Y, Lee P (1996) A general mechanics and dynamics model for helical end mills. Annals CIRP 45(1):59–64

Liu XW, Cheng K, Webb D, Luo XC (2002) Improved dynamic cutting force model in peripheral milling. Part I: theoretical model and simulation. Int J Adv Manuf Technol 20(9):631–638

Liu XW, Cheng K, Longstaff AP, Widiyarto MH, Ford D (2005) Improved dynamic cutting force model in ball-end milling. Part I: theoretical modelling and experimental calibration. Int J Adv Manuf Technol 26(5-6):457–465

Stabler GV (1951) The fundamental geometry of cutting tools. Proc Inst Mech Eng 165:14–21

Komanduri R, Von Turkovich BF (1981) New observations on the mechanism of chip formation when machining titanium alloys. Wear 69(2):179–188

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, G., Sui, S. & Tang, L. Precision prediction of cutting force in oblique cutting operation. Int J Adv Manuf Technol 81, 553–562 (2015). https://doi.org/10.1007/s00170-015-7206-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7206-z