Abstract

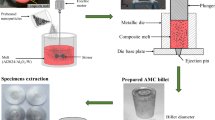

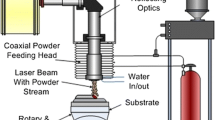

The current study investigates the overlays deposited by laser beam (LB) and gas tungsten arc (GTA) cladding with Inconel 52M filler wire in nuclear power plants. The effects of the deposition methods on the cross section profile, microstructures, and mechanical properties of both overlays are studied using optical microscope, scanning electron microscope (SEM), tensile and impact test and microhardness measurements. Experimental results show that LB cladding with higher wire feed rate improves the deposition efficiency as compared with GTA cladding. The microstructure of the LB clads consists of cellular and columnar dendrites, and Nb-rich spherical particles are precipitated in the interdendritic regions, while the equiaxed dendrites are dominant in the GTA clads. The microhardness of the GTA clads is 20–30 HV higher than that of the LB clads. Furthermore, the tensile strength, toughness, and elongation of the LB clads decrease in comparison to the GTA clads. The deep penetration of the LB clads resulting in a wave shape of each pass and high dilution does not benefit the mechanical properties as compared with the GTA clads.

Similar content being viewed by others

References

Kim JW, Lee K, Byun TS (2009) Local mechanical properties of alloy 82/182 dissimilar weld joint between SA508 Gr.1a and F316 SS at RT and 320 °C. J Nucl Mater 384:212–221

Xue H, Li ZJ, Lua ZP, Shojia TS (2011) The effect of a single tensile overload on stress corrosion cracking growth of stainless steel in a light water reactor environment. Nucl Eng Des 241:731–738

Takeuchi T, Kameda J, Nagai Y, Toyama T (2012) Microstructural changes of a thermally aged stainless steel submerged arc weld overlay cladding of nuclear reactor pressure vessels. J Nucl Mater 425:60–64

Bowerman BS, Czajkowski CJ, Roberts TC, Neal C (1999) Metallurgical evaluation of a feedwater nozzle to safe-end weld. Mater Charact 43:347–353

Takeuchi T, Kakubo Y, Matsukawa Y, Nozawa Y (2014) Effects of neutron irradiation on microstructures and hardness of stainless steel weld-overlay cladding of nuclear reactor pressure vessels. J Nucl Mater 449:273–276

Song TK, Oha CY, Kim JS, Kim YJ, Lee KS, Lee KS, Park CY (2011) The safe-end length effect on welding residual stresses in dissimilar metal welds of surge nozzles. Eng Fract Mech 78:1957–1975

Tobita T, Udagawa M, Chimi Y (2014) Effect of neutron irradiation on the mechanical properties of weld overlay cladding for reactor pressure vessel. J Nucl Mater 452:61–68

Shih YJ (2013) Mitigation of hot cracking of alloy 52M overlay on cast stainless steel CF8A. Sci Technol Weld Join 18:566–572

Ferguson JB, Lopez HF (2006) Oxidation products of Inconel alloys 600 and 690 in pressurized water reactor environments and their role in intergranular stress corrosion cracking. Metall Mater Trans A 37:2471–2479

Gao XL, Zhang LJ, Liu J, Zhang JX (2014) Effects of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. Int J Adv Manuf Technol 72:895–903

Borges B, Quintino L, Miranda RM, Carr P (2014) Imperfections in laser clading with powder and wire fillers. Int J Adv Manuf Technol 50:175–183

Sathiya P, Abdul Jaleel MY (2011) Influence of shielding gas mixtures on bead profile and microstructural characteristics of super austenitic stainless steel weldments by laser welding. Int J Adv Manuf Technol 54:525–535

Caiazzo F, Alfieri V, Schipani A, Cinque S (2013) Dissimilar autogenous disk-laser welding of Haynes 188 and Inconel 718 superalloys for aerospace applications. Int J Adv Manuf Technol 68:1809–1820

Baldridge T, Poling G, Foroozmehr E (2013) Laser cladding of Inconel 690 on Inconel 600 superalloy for corrosion protection in nuclear applications. Opt Lasers Eng 51:180–184

Liu S, Liu W, Harooni M, Ma JJ, Kovacevic R (2014) Real-time monitoring of laser hot-wire cladding of Inconel 625. Opt Laser Technol 62:124–134

Abioyea TE, McCartney DG, Clarea AT (2013) Laser cladding of Inconel 625 wire for corrosion protection. J Mater Process Technol 213:2145–2151

Jeng SL, Chang YH (2012) The influence of Nb and Mo on the microstructure and mechanical properties of Ni-Cr-Fe GTAW welds. Mater Sci Eng A 555:1–12

Kuo TY, Lee HT (2002) Effects of filler metal composition on joining properties of alloy 690 weldments. Mater Sci Eng A 338:202–212

Chu HA, Young MC, Chu HC, Tsay LW, Chen C (2013) Hot cracking susceptibility of Alloy 52M weld overlays onto CF8 stainless steel. J Nucl Mater 433:419–423

Jeng SL, Chang YH (2013) Microstructure and flow behavior of Ni–Cr–Fe welds with Nb and Mo additions. Mater Sci Eng A 560:343–350

Li G, Zhang ML, Huang J, Sun ZY, Wu YX (2015) Studies of electroslag cladding Inconel 52M multilayer. Surf Eng 31:52–57

Naffakh H, Shamanian M, Ashrafizadeh F (2008) Weldability in dissimilar welds between type 310 austenitic stainless steel and alloy 657. J Mater Sci 43:5300–5304

Zhang YN, Cao X, Wanjara P (2013) Microstructure and hardness of fiber laser deposited Inconel 718 using filler wire. Int J Adv Manuf Technol 69:2569–2581

Dehmolaei R, Shamanian M, Kermanpur A (2008) Microstructural characterization of dissimilar welds between alloy 800 and HP heat-resistant steel. Mater Charact 59:1447–1454

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, G., Zhang, M., Huang, J. et al. A comparative study on microstructure and properties of Inconel 52M overlays deposited by laser beam and GTA cladding. Int J Adv Manuf Technol 81, 103–112 (2015). https://doi.org/10.1007/s00170-015-7198-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7198-8