Abstract

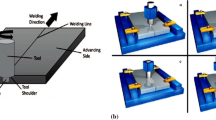

Three-dimensional nonlinear thermal simulations are carried out for the friction stir welding (FSW) of 304L stainless steel using finite element analysis software—COMSOL® Multiphysics. Based on published experimental data of transient temperature for the Stainless Steel 304L, the thermal numerical simulation is verified. Cases of parametric sweeps for a few important welding parameters like normal force (5–50 kN), rotational speed (200–1500 RPM), shoulder radius (10–50 mm), and translational speed (0.5–3 mm s−1) are analyzed at three specific locations for the friction stir welding process. The objective of this analysis is to study the effect on transient temperature during the welding operation with varying parameters. The validated model is extended to parametric study of variation of transient temperature with shoulder radius and normal force that have not yet been experimentally validated. Transient temperature is an important factor for successful fusion of metal. The simulation shows an increasing trend of the peak temperature with increasing tool rotational speed, decreasing travel speed, increasing shoulder radius, and increasing normal force. This analysis can assist in choosing optimum welding parameters for successful welding under various constraints and for prediction and control of heat-affected zone.

Similar content being viewed by others

References

Arora A, Nandan R, Reynolds AP, DebRoy T (2009) Torque, power requirement and stir zone geometry in friction stir welding through modeling and experiments. Scr Mater 60:13–16

Awang M, Mucino V, Feng Z, David S (2006) Thermo-mechanical modeling of friction stir spot welding (FSSW), SAE Technical Paper 2006-01-1392, doi:10.4271/2006-01-1392.

Brown WF, Mindlin H, Ho CY (1993) Aerospace structural metals handbook. CINDAS/USAF CRDA Handbooks Operation and Purdue University, West Lafayette, IN, USA

Chao YJ, Qi X (1998) Thermal and thermo-mechanical modeling of friction stir welding of aluminum alloy 6061-T6. J MatProc Manuf Sci 7:215–233

Colegrove P (2000) Three dimensional flow and thermal modeling of the friction stir welding process, Proceedings of the second International Symposium on Friction Stir Welding, Sweden

COMSOL (2011) Multiphysics user’s guide, version 4.2

Deng Z, Lovell MR, Tagavi KA (2001) Influence of material properties and forming velocity on the interfacial slip characteristics of cross wedge rolling. J Manuf Sci Eng-Trans Asme 123(4):647–653

Doherty RD, Hughes DA, Humphreys FJ, Jonas JJ, Jensen DJ, Kassner ME, King WE, McNelley TR, McQueen HJ, Rollett AD (1997) Current issues in recrystallization: a review. Mat Sci Eng A 238:219–274

Kim YC, Fuji A, North TH (1995) Residual stress and plastic strain in AISI 304L stainless steel/titanium friction welds. Mater Sci Technol 11:383–388

Maeda M, Liu H, Fujii H, Shibayanagi T (2005) Temperature field in the vicinity of FSW-tool during friction stir welding of aluminum alloys. Weld World 49(3):69–75, 2005.04

Mahoney MW, Rhodes CG, Flintoff JG, Spurling RA, Bingel WH (1998) Properties of friction stir welded 7075 T651 aluminium, metallurgical and materials transactions A, vol. 29 pp. 1955–1964

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mat Sci Eng, Reports: Rev J 50:1–78

Mushin JJ, Moneer HT, Muhammed A (2012) Theoretical and experimental investigation of transient temperature distribution in friction stir welding of AA 7020-T53, Journal of Engineering 18 pp. 693, viewed on 10/12/2013 available at http://www.iasj.net/iasj?func=fulltext&aId=41359

Nandan R, Roy GG, Lienert TJ, DebRoy T (2006) Numerical modelling of 3D plastic flow and heat transfer during friction stir welding of stainless steel. Sci Technol Weld Join 11(5):526–537

Neto DM, Neto P (2013) Numerical modeling of friction stir welding process: a literature review. Int J Adv Manuf Technol 65:115–126

Rajakumar S, Razalrose A, Balasubramanian V (2013) Friction stir welding of AZ61A magnesium alloy: a parametric study (2011). Int J Adv Manuf Technol 68:277–292

Reynolds AP, Lockwood WD, Seidel TU (2000) Processing–property correlation in friction stir welds. Mater Sci Forum 331–337:1719–1724

Reynolds AP, Posada M, Deloach J, Skinner MJ, Halpin J, Lienert TJ (2001) FSW of austenitic stainless steels, In: Proceedings of the Third International Symposium on Friction Stir Welding, Kobe, Japan

Rhodes CG, Mahoney MW, Bingel WH, Spurling RA, Bampton CC (1997) Effects of friction stir welding on microstructure of 7075 aluminium. Scr Mater 36:69

Riahi M, Nazari H (2011) Analysis of transient temperature and residual thermal stresses in friction stir welding of aluminum alloy 6061-T6 via numerical simulation. Int J Adv Manuf Technol 55:143–152

Russell MJ, Sheercliff HR (1999) Analytic modeling of microstructure development in friction stir welding, Proceedings of the First International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA

Sato YS, Urata M, Kokawa H (2002) Parameters controlling microstructure and hardness during friction stir welding of precipitation-hardenable aluminum alloy 6063. Metall Mater Trans A 33A–3:625–635

Sato YS, Kokawa H, Enmoto M, Jogan S (1999) Precipitation sequence in friction stir weld of 6063 aluminium during aging. Metall Mater Trans A 30(12):3125–3130

Song M, Kovacevic R (2002) A new heat transfer model for friction stir welding, transactions of the North American Manufacturing Research Institution of SME. Vol. XXX SME, Dearborn, MI, pp. 565-572

Song M, Kovacevic R (2003) Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int J Mach Tools Manuf 43:605–615

Tang W, Guo X, McClure JC, Murr LE, Nunes A (1998) Heat input and temperature distribution in friction stir welding. J Mater Process Manuf Sci 37(2):163–172

Thomas WM, Nicholas ED, Needham JC, Church MG, Templesmith P, Dawes C (1991) Int. Patent PCT/GB92/02203 and GB Patent 9125978.9

Ugender S, Kumar A, Reddy AS (2014) Microstructure and mechanical properties of AZ31B magnesium alloy by friction stir welding, 3rd International Conference on Materials Processing and Characterisation (ICMPC 2014). Procedia Mat Sci 6:1600–1609

Ulysse P (2002) Three-dimensional modelling of the friction stir-welding process. Int J Mach Tools Manuf 42:1549–1557

Zhu XK, Chao YJ (2004) Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel. J Mater Process Technol 146:263–272

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chansoria, P., Solanki, P. & Dasgupta, M.S. Parametric study of transient temperature distribution in FSW of 304L stainless steel. Int J Adv Manuf Technol 80, 1223–1239 (2015). https://doi.org/10.1007/s00170-015-7102-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7102-6