Abstract

In gas tungsten arc welding (GTAW), the weld pool is the major source of information that can be used to assure the production of the desired weld penetration—the most critical factor determining the weld integrity. To meet this challenge, various sensing technologies, modeling methods, and control strategies have been studied, and artificial intelligence technologies were applied to improve system intelligence. The GTAW process analysis is given first. Then, a short introduction on weld pool sensing technologies is presented, where three-dimensional (3D) vision sensing is a very active orientation. Furthermore, weld pool description model and characteristic parameter model are also discussed, where intelligent algorithms were used generally. Besides, dynamic modeling and penetration control strategies, especially intelligent control strategies are presented. At last, the discussion about development of the GTAW penetration control product is analyzed briefly.

Similar content being viewed by others

References

Connor LP, O’Brien RL, Oates WR (2007) Welding handbook: welding processes, part 2. American Welding Society, Miami

Zhang YM (2008) Real-time weld process monitoring. Woodhead Publishing in Materials, ISBN 978-1-84569-268-1, Cambridge, England

Chen SB, Wu J (2008) Intelligentized methodology for arc welding dynamical processes: visual information acquiring, knowledge modeling and intelligent control. ISBN 3540856412, Sрringer

Wang XW (2014) Three-dimensional vision-based sensing of GTAW: a review. Int J Adv Manuf Technol 72:333–345

Wang XW (2013) Weld pool surface model establishment for GTAW based on 3D reconstruction technology. Proc 2013 Chin Intell Autom Conf Lect Notes Electr Eng 255:741–748

Zhang WJ, Liu YK, Wang XW, Zhang YM (2012) Characterization of three dimensional weld pool surface in GTAW. Weld J 91(7):195s–203s

Zhang WJ, Wang XW, Zhang YM (2013) Analytical real-time measurement of a three-dimensional weld pool surface. Meas Sci Technol 24:115011 (18pp)

Zhang WJ (2014) Modeling of human welder behavior in gas tungsten arc welding of stainless steel tubes. Weld World 58:601–617

Wang XW, Li RR (2014) Intelligent modelling of back-side weld bead geometry using weld pool surface characteristic parameters. J Intell Manuf 25(6):1301–1313

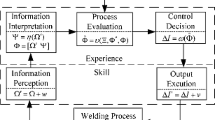

Zhang WJ, Zhang YM (2012) Modeling of human welder response to 3D weld pool surface: part I-principles. Weld J 91(11):310s–318s

Zhang WJ, Zhang YM (2012) Modeling of human welder response to 3D weld pool surface: part II-results and analysis. Weld J 91(12):329s–337s

Zhang WJ, Zhang YM (2012) Dynamic control of GTAW process using human welder response model. Weld J 92(5):154s–166s

Liu YK, Zhang YM (2014) Control of human arm movement in machine-human cooperative welding process. Control Eng Pract 32:161–171

Liu YK, Zhang YM (2013) Control of 3D weld pool surface. Control Eng Pract 21:1469–1480

Liu YK, Zhang WJ, Zhang YM (2013) Dynamic neuro-fuzzy-based human intelligence modeling and control in GTAW. IEEE Trans Autom Sci Eng 99:1–12

Liu YK, Zhang YM (2013) Model-based predictive control of weld penetration in gas tungsten arc welding. IEEE Trans Control Syst Technol 22(3):955–966

Kovacevic R, Cao ZN, Zhang YM (1996) Roles of welding parameters in determining the geometrical appearance of weld pool. J Eng Mater Technol Trans ASME 118(4):589–596

Jou M (2003) Experimental study and modeling of GTA welding process. J Manuf Sci Eng 125:801–808

Zhao PC, Wu CS, Zhang YM (2004) Numerical simulation of dynamic characteristics of weld pool geometry with step-changes of welding parameters. Model Simul Mater Sci Eng 12(5):765–780

Zhang YM, Kovacevic R, Li (1996) Characterization and real-time measurement of geometrical appearance of weld pool. Int J Mach Tools Manuf 36(7):799–816

Zhang YM, Li L, Kovacevic R (1997) Dynamic estimation of full penetration using geometry of adjacent weld pools. J Manuf Sci Eng Trans ASME 119(4):631–643

Yasuo S (1999) Measurement of molten pool shape and penetration control applying neural network in TIG welding of thin steel plates. ISIJ Int 39(10):1075–1080

Tarng YS, Wu JL, Yen SS, Juang SC (1999) Intelligent modeling and optimization of the gas tungsten arc welding. J Intell Manuf 10:73–79

Wang B, Chen SB, Wang JJ (2005) Rough set based knowledge modeling for the aluminum alloy pulsed GTAW process. Int J Adv Manuf Technol 25(9):902–908

Kong M, Chen SB (2009) Al alloy weld pool control of welding robot with passive vision. Sens Rev 29(1):28–37

Zhao DB, Chen SB, Wu L, Dai M, Chen Q (2001) Intelligent control for the shape of the weld pool in pulsed GTAW with filler metal. Weld Res Suppl 80(11):253s–260s

Wu CS, Gao JQ (2006) Vision-based neuro-fuzzy control of weld penetration in gas tungsten arc welding of thin sheets. Int J Model Identif Control 1(2):126–132

Subashini L, Vasudevan M (2012) Adaptive neuro-fuzzy inference system (ANFIS)-based models for predicting the weld bead width and depth of penetration from the infrared thermal image of the weld pool. Metall Mater Trans B 43B(2):145–154

Zhang YM, Wu L, Walcott B, Chen DH (1993) Determining joint penetration in GTAW with vision sensing of weld-face geometry. Weld J 72(10):463s–469s

Chokkalingham S, Chandrasekhar N, Vasudevan M (2012) Predicting the depth of penetration and weld bead width from the infrared thermal image of the weld pool using artificial neural network modeling. J Intell Manuf 23:1995–2001

Giridharan PK, Murugan N (2009) Optimization of pulsed GTA welding process parameters for the welding of AISI 304L stainless steel sheets. Int J Adv Manuf Technol 40(5–6):478–489

Lu W, Zhang YM, Emmerson J (2004) Sensing of weld pool surface using non-transferred plasma charge sensor. Meas Sci Technol (15):991–999

Lu W, Zhang YM (2006) Robust sensing and control of the weld pool surface. Meas Sci Technol 17:2437–2446

Zhang YM, Kovacevic R (1998) Neurofuzzy model based predictive control of weld fusion zone geometry. IEEE Trans Fuzzy Syst 6(3):389–401

Zhang YM, Kovacevic R, Wu L (1996) Dynamic analysis and identification of gas tungsten arc welding process for full penetration control. J Eng Ind Trans ASME 118(1):123–136

Zhang YM, Kovacevic R, Li L (1996) Adaptive control of full penetration GTA welding. IEEE Trans Control Syst Technol 4(4):394–403

Luo H, Devanathan R, Wang J, Chen X, Sun Z (2002) Vision based neurofuzzy logic control of weld pool geometry. Sci Technol Weld Join 7(5):321–325

Fan CJ, Lv FL, Chen SB (2009) Visual sensing and penetration control in aluminum alloy pulsed GTA welding. Int J Adv Manuf Technol 42(1–2):126–137

Chen SB, Wu J, Du QY (2011) Non-linear modeling and compound intelligent control of pulsed gas tungsten arc welding dynamics. Proc Inst Mech Eng I J Syst Control Eng 225:113–124

Zhang YM, Kovacevic R (1997) Robust control of interval plants: a time domain approach. IEE Proc Control Theory Appl 144(4):347–353

Tsai CH, Hou KH, Chuang HT (2006) Fuzzy control of pulsed GTA welds by using real-time root bead image feedback. J Mater Process Technol 176(6):158–167

Servo-Robot http://www.meta-mvs.com/index.htm

Meta vision system http://www.servorobot.com/

Chen SB, Lv N (2014) Research evolution on intelligentized technologies for arc welding process. J Manuf Process 16:109–122

Xu YL, Lv N, Zhong JY, Chen HB, Chen SB (2012) Research on the real-time tracking information of three-dimension welding seam in robotic GTAW process based on composite sensor technology. J Intell Robot Syst 68:89–103

Fang HC, Ong SK, Nee AYC (2013) Orientation planning of robot end-effector using augmented reality. Int J Adv Manuf Technol 67(9–12):2033–2049

Nee AYC, Ong SK, Chryssolouris G, Mourtzis D (2012) CIRP Ann Manuf Technol 61(2):657–679

Chen CJ, Hong J, Wang SF (2015) Automated positioning of 3D virtual scene in AR-based assembly and disassembly guiding system. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6321-6

Chen SJ, Huang N, Liu YK, Zhang YM (2015) Machine-assisted travel speed control in manual welding torch operation. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6310-9

Li GY, Xu FX, Sun GY, Li Q (2014) Identification of mechanical properties of the weld line by combining 3D digital image correlation with inverse modeling procedure. Int J Adv Manuf Technol 74(5–8):893–905

Wang XW, Huang Y, Zhang YM (2013) Droplet transfer model for laser enhanced GMAW. Int J Adv Manuf Technol 64(1):207–217

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X. Three-dimensional vision applications in GTAW process modeling and control. Int J Adv Manuf Technol 80, 1601–1611 (2015). https://doi.org/10.1007/s00170-015-7063-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7063-9