Abstract

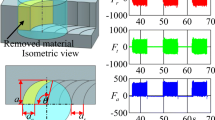

In turn-milling machining, we found the cutter wear concentrated on a small section around the corner of the cutter and affect the cutter life. In this paper, the idea of swept area is proposed firstly based on the analyses for cutter wear, and it can indicate the cutter wear. Balance of swept area will lead to balanced wear along cutting edge, and expressions of swept areas of infinitesimal elements on the cutting edge are given. Secondly, the cutting depth and cutting angle, which are the key parameters in calculating the swept area, are analyzed based on different contact situations between the cutter and workpiece, and the detailed calculating method is given. Then, the optimization model to balance swept areas along the cutting edge is established, and the cutting parameters including cutter offset and machining length are optimized. Finally, the orthogonal turn-milling machining experiments with different cutting parameters are conducted; the result shows that turn-milling with optimized parameters can actually balance the cutter wear and increase the cutter life.

Similar content being viewed by others

References

Schulz H, Spur G (1990) High speed turn-milling—a new precision manufacturing technology for the machining of rotationally symmetrical work-pieces. Ann ICRP Manuf Technol 1(39):107–109

Savas V, Ozay C (2008) The optimization of the surface roughness in the process of tangential turn-milling using genetic algorithm. Int J Adv Manuf Technol 37:335–340

Zhu L, Li H, Wang W (2013) Research on rotary surface topography by orthogonal turn-milling. Int J Adv Manuf Technol 69:2279–2292

Karaguzel U, Bakkal M, Budak E (2012) Process modeling of turn-milling using analytical approach. 3rd ICRP Conf Process Mach Interact 4:131–139

Kopac J, Pogacnik M (1997) Theory and practice of achieving quality surface in turn milling. Int J Mach Tools Manuf 37(5):709–715

Choudhury SK, Mangrulkar KS (2000) Investigation of orthogonal turn-milling for the machining of rotationally symmetrical work pieces. J Mater Process Technol 1–3(99):120–128

Sun J, Liang Y (2009) Analyzing the tool wear intensity for turn-milling processing. Manuf Technol Mach Tool 11:61–63, In Chinese

Lin J, Lee S-l, Weng C-l (1992) Estimation of cutting temperature in high-speed machining. J Eng Mater Technol 114:289–296

Sabberwal AJP (1960) Chip section and cutting force during the end milling operation. Ann ICRP 10(3):197–203

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yonglin, C., Yemeng, M., Chao, H. et al. Swept area modeling and cutter wear study in turn-milling. Int J Adv Manuf Technol 80, 775–789 (2015). https://doi.org/10.1007/s00170-015-7021-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7021-6