Abstract

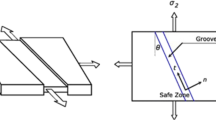

In some recent sheet metal forming processes such as hydroforming and incremental forming processes, normal and through thickness stresses are induced over the metal sheet, and therefore, prediction of forming limits requires considering effect of these stresses. In this investigation, a modified M–K model has been utilized to consider general stress state including normal and through thickness shear stresses on anisotropic metal sheet. This is achieved by assuming additional force equilibrium and geometrical compatibility between groove and matrix, and the numerical model has been solved by Newton–Raphson method to calculate the limiting strains. Forming limit diagrams resulting from this model have been evaluated with some published experimental data, and a good accordance between the results has been observed. It has also been concluded that exertion of normal and through thickness stresses enhances forming limits significantly.

Similar content being viewed by others

References

Hashiguchi K, Protasov A (2004) Localized necking analysis by the subloading surface model with tangential-strain rate and anisotropy. Int J Plast 20:1909–1930

Boudeau N, Gelin JC, Salhi S (1998) Computational prediction of the localized necking in sheet forming based on microstructural material aspects. Comput Mater Sci 11:45–64

Bressan JD, Williams JA (1983) The use of a shear instability criterion to predict local necking in sheet metal deformation. Int J Mech Sci 25:155–168

Marciniak Z, Kuczynski K (1967) Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci 9:609–620

Hutchinson JW, Neale KW (1977) Sheet necking II: time-independent behaviour. In: Koistinen DP, Wang NM (eds) Mechanics of sheet metal forming: material behavior and deformation analysis: 1977 GMR Symposium

Shakeri M, Sadough A, Dariani BM (2000) Effect of pre-straining and grain size on the limit strains in sheet metal forming. Proc IME B 214:821–827

Azodi HD, Dariani BM (2003) Finding the optimum hill index in the determination of the forming limit diagram. Proc IME B 217:1677–1683

Lian F, Barlat F, Baudelet B (1989) Plastic behaviour and stretchability of sheet metals. Part II: effect of yield surface shape on sheet forming limit. Int J Plast 5:131–147

Xu S, Weinmann KJ (1998) Prediction of forming limit curves of sheet metals using Hill’s 1993 user-friendly yield criterion of anisotropic metals. Int J Mech Sci 42:677–692

Kuroda M, Tvergaard V (2000) Forming limit diagram for anisotropic metal with different yield criteria. Int J Solid Struc 37:5037–5059

Chow CL, Yu LG, Tai WH, Demeri MY (2001) Prediction of forming limit diagrams for AL6111-T4 under non-proportional loading. Int J Mech Sci 43:471–486

Butuc MC, Barata da Rocha A, Ferreira Duarte J (2002) A more general model for forming limit diagrams prediction. J Mater Proc Technol 125–126:213–218

Banabic D, Dannenmann E (2001) Prediction of the influence of yield locus on the limit strains in sheet metals. J Mater Proc Technol 109:9–12

Knockaert R, Chastel Y, Massoni E (2002) Forming limits prediction using rate-independent polycrystalline plasticity. Int J Plast 18(2):231–247

Signorelli JW, Bertinetti MA, Turner PA (2009) Predictions of forming limit diagrams using a rate-dependent polycrystal self-consistent plasticity model. Int J Plast 25:1–25

Neil JC, Agnew SR (2009) Crystal plasticity-based forming limit prediction for non-cubic metals: application to Mg alloy AZ31B. Int J Plast 25:379–398

Matin PH, Smith LM (2005) Practical limitations to the influence of through-thickness normal stress on sheet metal formability. Int J Plast 21:671–690

Assempour A, Nejadkhaki HK, Hashemi R (2010) Forming limit diagrams with the existence of through-thickness normal stress. Comput Mater Sci 48:504–508

Banabic D, Soare S (2008) On the effect of the normal pressure upon the forming limit strains. In: Hora P (Ed.), Proceedings of the 7th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes, Interlaken, Switzerland, pp. 199–204

Wu PD, Embury JD, Lloyd DJ, Huang Y, Neale KW (2009) Effects of superimposed hydrostatic pressure on sheet metal formability. Int J Plast 25:1711–1725

Emmens WC, van den Boogaard AH (2009) An overview of stabilizing deformation mechanisms in incremental sheet forming. J Mater Process Technol 209:3688–3695

Silva MB, Nielsen PS, Bay N, Martins PAF (2011) Failure mechanisms in single point incremental forming of metals. Int J Adv Manuf Technol 56:893–903

Silva MB, Skjoedt M, Atkins AG, Bay N, Martins PAF (2008) Single point incremental forming & formability/failure diagrams. J Strain Anal Eng Des 43:15–36

Isik K, Silva MB, Tekkaya AE, Martins PAF (2014) Formability limits by fracture in sheet metal forming. J Mater Proc Technol 214:1557–1565

Bambach M, Hirt G (2008) Investigation into the prediction of forming limits in incremental sheet metal forming using damage models. In: Yang DY, Kim YH, Park CH (eds) ICTP 2008 International Conference on Technology of Plasticity. The Korean Society for Technology of Plasticity, Gyeongju, pp 1777–1782

Eyckens P, Van Bael A, Van Houtte P (2009) Marciniak–Kuczynski type modelling of the effect of through-thickness shear on the forming limits of sheet metal. Int J Plast 25:2249–2268

Eyckens P, Van Bael A, Van Houtte P (2011) An extended Marciniak–Kuczynski model for anisotropic sheet subjected to monotonic strain paths with through-thickness shear. Int J Plast 27:1577–1597

Allwood JM, Shouler DR (2009) Generalised forming limit diagrams showing increased forming limits with non-planar stress states. Int J Plast 25:1207–1230

Stachowicz F (1988) Effect of annealing temperature on plastic flow properties and forming limit diagrams of titanium and titanium alloy sheets. Trans Jpn Inst Metals 29:484–493

Sing WM, Rao KP (1995) Influence of material properties on sheet metal formability limits. J Mater Proc Technol 48:35–41

Hwang YM, Lin YK, Chuang HC (2009) Forming limit diagrams of tubular materials by bulge tests. J Mater Proc Technol 209:5024–5034

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fatemi, A., Mollaei Dariani, B. Forming limit prediction of anisotropic material subjected to normal and through thickness shear stresses using a modified M–K model. Int J Adv Manuf Technol 80, 1497–1509 (2015). https://doi.org/10.1007/s00170-015-7001-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7001-x