Abstract

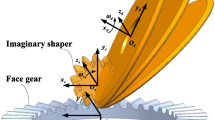

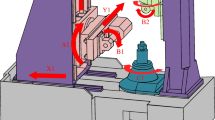

In order to improve the machining accuracy and production efficiency of face gear, a generating grinding method for face gear using cubic boron nitride (CBN) wheel is studied in this paper. The mathematical model of the CBN wheel profile is derived based on face gear grinding principle and theory of gearing. Taking the demands of machine motion during face gear grinding into account, a five-axis face gear grinding machine is developed. Then, the mathematical model of the ground face gear and the grinding method are proposed based on the structure of the machine. For reducing the face gear tooth profile errors induced by installation errors, an error analysis model of face gear grinding is established; the effects of installation errors on tooth profile errors are analyzed. The CBN wheel was manufactured, and the grinding experiments were performed on the self-developed grinding machine. The processing parameters of face gear grinding were amended according to the tooth flank measurement results obtained from coordinate measuring machine. The ground tooth profile deviation was reduced significantly after processing parameters amendment. Experiment results demonstrate that the generating grinding method is an effective approach to achieve the precision grinding of face gear.

Similar content being viewed by others

References

Deng XZ, Li DG, Wei BY, Deng J (2014) Face-milling spiral bevel gear tooth surfaces by application of 5-axis CNC machine tool. Int J Adv Manuf Technol 71(5–8):1049–1057

Wang YZ, Wu CH, Gong K, Wang S, Zhao XF, Lv QJ (2012) Loaded tooth contact analysis of orthogonal face gear drives. Proc Inst Mech Eng Part C - J Eng Mech Eng Sci 226(9):2309–2319

Heath GF, Filler RR, Tan J (2002) Development of face gear technology for industrial and aerospace power transmission. NASA/CR-2002-211320

Lewicki DG, Heath GF, Filler RR, Slaughter SC, Fetty J (2007) RDS-21 face-gear surface durability tests. NASA/TM-2007-214970

Shih YP, Chen SD (2012) A flank correction methodology for a five-axis gear profile grinding machine. Mech Mach Theory 47:31–45

Radzevich SP, Krehel R (2012) Determination of the grinding wheel profile and its setup for use in finishing cylindrical gears with an evolvent profile. Int J Adv Manuf Technol 63(9–12):875–879

Liu YP, Gong J, Wu XT (2013) Investigation on the grinding of elliptical gears with CNC conical wheel gear grinder. Int J Adv Manuf Technol 64(1–4):349–256

Yi JJ, Ding YJ, Zhao SH, Ji BY, Zhou JJ (2009) A novel technique of polishing gear working surface using PECMP. Int J Precis Eng Manuf 10(4):57–62

Michalski J (2009) Surface topography of the cylindrical gear tooth flanks after machining. Int J Adv Manuf Technol 63(5–6):513–528

Shih YP, Huang YC, Lee YH, Wu JM (2013) Manufacture of face-hobbed straight bevel gears using a six-axis CNC bevel gear cutting machine. Int J Adv Manuf Technol 68(9–12):2499–2515

Tang JY, Yin F, Chen XM (2013) The principle of profile modified face-gear grinding based on disk wheel. Mech Mach Theory 70:1–15

Litvin FL, Fuentes A, Zanzi C, Pontiggia M (2002) Design, generation, and stress analysis of two versions of geometry of face-gear drives. Mech Mach Theory 37(10):1179–1211

Litvin FL, Fuentes A, Zanzi C, Pontiggia M, Handschuh RF (2002) Face-gear drive with spur involute pinion: geometry, generation by a worm, stress analysis. Comput Meth Appl Mech Eng 191(25–26):2785–2813

Binney DA, Vinayak H, Gmirya Y, Zunski LM, Houser DR, Ames EC (2003) Face gear transmission development program at Sikorsky Aircraft. ASME 2003 Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, USA, pp 1–7

Litvin FL, Perez IG, Fuentes A, Vecchiato D, Hansen BD, Binney D (2005) Design, generation and stress analysis of face-gear drive with helical pinion. Comput Meth Appl Mech Eng 194(36–38):3870–3901

Heath GF, Slaughter SC, Fisher DJ, Lewicki DG, Fetty J (2011) Helical face gear development under the enhanced rotorcraft drive system program. NASA/TM-2011-217125

Huang Y, Chou YK, Liang SY (2007) CBN tool wear in hard turning: a survey on research progresses. Int J Adv Manuf Technol 35(5–6):443–453

Miao Q, Ding WF, Xu JH, Yang CY, Fu YC (2013) Fractal analysis of wear topography of brazed polycrystalline cBN abrasive grains during grinding nickel super alloy. Int J Adv Manuf Technol 68(9–12):2229–2236

Köhler J, Schindler A, Woiwode S (2012) Continuous generating grinding—tooth root machining and use of CBN-tools. CIRP Ann Manuf Technol 61(1):291–294

Ding WF, Miao Q, Xu JH, Ma CY, Zhao B, Yang CY (2013) Joining interface and grain fracture of single-layer brazed grinding wheels with binderless CBN grains. Int J Adv Manuf Technol 68(5–8):1261–1266

You HY, Ye PQ, Wang JS, Deng XY (2003) Design and application of CBN shape grinding wheel for gears. Int J Mach Tools Manuf 43(12):1269–1277

Gawronski Z, Kruszynski B, Kula P (2005) Synergistic effects of thermo-chemical treatment and super abrasive grinding in gears’ manufacturing. J Mater Process Technol 159(2):249–256

Wei J, Zhang Q, Xu ZZ, Lyu SK (2010) Study on precision grinding of screw rotors using CBN wheel. Int J Precis Eng Manuf 11(5):651–658

Wei J, Zhang GH (2010) A precision grinding method for screw rotors using CBN grinding wheel. Int J Adv Manuf Technol 48(5–8):495–503

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Lan, Z., Hou, L. et al. A precision generating grinding method for face gear using CBN wheel. Int J Adv Manuf Technol 79, 1839–1848 (2015). https://doi.org/10.1007/s00170-015-6962-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6962-0