Abstract

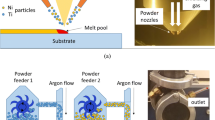

The fabrication of biomedical devices using Ni-Ti compositions is limited to conventional techniques and the use of near equiatomic pre-alloyed Ni and Ti powders. In this study, functionally graded walls and cylinder built by concurrent feeding of Ni powder and commercially pure (CP) Ti wire using direct laser metal deposition technique are presented. The built structures consist of CP Ti wire-deposited layers and Ni-Ti layers of varying Ni composition. The microstructures of the built Ni-Ti structures including phase identification, phase compositions and area fractions of the phases present at various processing parameters were determined using a combination of scanning electron microscopy/energy dispersive X-ray spectroscopy, X-ray diffractometry and image processing software. Vickers micro-hardness test was conducted on the deposited structures. It was found that the Ni-Ti layers comprise of NiTi and NiTi2 phases. The area fraction of the NiTi phase increases, whereas NiTi2 decreases with increasing the Ni powder feed rate. Ni-Ti layers with higher area fractions of NiTi2 phase are found to be harder with a maximum of 513 HV0.3 found in this study. The micro-hardness of Ni-Ti layers is, by at least a factor of 1.5, higher than the CP Ti wire laser-deposited layers.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Elahinia MH, Hashemi M, Tabesh M, Bhaduri SB (2012) Manufacturing and processing of NiTi implants: a review. Prog Mater Sci 57:911–946

Man HC, Zhang S, Cheng FT, Guoc X (2005) Laser fabrication of porous surface layer on NiTi shape memory alloy. Mater Sci Eng A 404:173–178

Yan XJ, Gugel H, Huth S, Theisen W (2011) Microstructures and properties of laser cladding NiTi alloy with W for biomedical applications. Mater Lett 65:2934–2936

Dayananda GN, Varughese B, Harish Kumar T, Subba Rao M (2005) Development of an SMA based smart landing gear for rotorcraft and other similar applications, in Proceedings of Fourth International Conference on Smart Materials, Structures and Systems. Bangalore, India. p SB–36 to 44

Clare AT, Paul RC, Davies S, Sutcliffe JC, Tsopanos S (2008) Selective laser melting of high aspect ratio 3D nickel–titanium structures two way trained for MEMS applications. Int J Mech Mater Des 4(2):181–187

Fadlallah SA, El-Bagoury N, Gad El-Rab SMF, Ahmed RA, El-Ousamii G (2014) An overview of NiTi shape memory alloy: corrosion resistance and antibacterial inhibition for dental application. J Alloys Compd 583:455–464

Kosec T, Mocnik P, Legat A (2014) The tribocorrosion behaviour of NiTi alloy. Appl Surf Sci 288:727–735

Ng KW, Man HC, Yue TM (2011) Characterization and corrosion study of NiTi laser surface alloyed with Nb or Co. Appl Surf Sci 257(8):3269–3274

Abioye TE, Folkes J, Clare AT (2013) A parametric study of Inconel 625 wire laser deposition. J Mater Process Technol 213(12):2145–2151

Azo Materials. Titanium alloys - Ti-6Al-4V Grade 5. 2002. Available at www.azom.com/article.aspx?articleID=1547. Accessed on 15th Dec., 2014.

Farayibi PK, Folkes JA, Clare AT (2013) Laser deposition of Ti-6Al-4V wire with WC for functionally graded components. J Mater Manuf Process 28(1–5):514–518

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Abioye, T.E., Farayibi, P.K., Kinnel, P. et al. Functionally graded Ni-Ti microstructures synthesised in process by direct laser metal deposition. Int J Adv Manuf Technol 79, 843–850 (2015). https://doi.org/10.1007/s00170-015-6878-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6878-8