Abstract

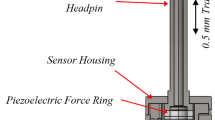

Injection molding part quality is modeled using a multivariate sensor. Melt pressure and temperature are respectively obtained through the incorporation of a piezo-ceramic element and infrared thermopile within the sensor head. Melt velocity is derived from the transient response of the melt temperature as the polymer melt flows across the sensor’s lens. The apparent melt viscosity is then derived based on the melt velocity and the time derivative of the increasing melt pressure given the cavity thickness. Quality metrics taken into account are finished part thickness, width, length, weight, and tensile strength. A 12-run, blocked half-fractional design of experiments was performed to derive predictive models for part mass, dimensions, and structural properties. Several predictive part quality models were created using data from the machine, a suite of commercial sensors, the multivariate sensor, and combinations thereof. The results indicate that multiple orthogonal streams of process data yield higher-fidelity models with coefficients of determination approaching one. Furthermore, best subset analysis indicates that the most important process data are gathered from in-mold sensors, where the acquired information is closest to the states of the polymer forming the final product.

Similar content being viewed by others

References

SPI (2012) Size and impact of the plastics industry on the U.S. economy, ed: Society of the Plastics Industry

Chen Z, Turng LS (2005) A review of current developments in process and quality control for injection molding. Adv Polym Technol 24:165–182

Mann JW (1974) Process parameter control: the key to optimization. Plast Eng 30:25–27

Coates PD, Speight RG (1995) Towards intelligent process control of injection moulding of polymers. Proc Inst Mech Eng B J Eng Manuf 209:357–367

Dubay R, Bell AC, Gupta YP (1997) Control of plastic melt temperature: a multiple input multiple output model predictive approach. Polym Eng Sci 37:1550–1563

Tanner I (2000) Engineering rheology

Malkin AY, Isayev AI (2005) Rheology: concepts, methods, and applications: ChemTec Publishing

Diduch C, Dubay R, Li WG (2004) Temperature control of injection molding. Part I: modeling and identification. Polym Eng Sci 44:2308–2317

Kurt M, Kaynak Y, Kamber OS, Mutlu B, Bakir B, Koklu U (2010) Influence of molding conditions on the shrinkage and roundness of injection molded parts. Int J Adv Manuf Technol 46:571–578

Hassan H (2013) An experimental work on the effect of injection molding parameters on the cavity pressure and product weight. Int J Adv Manuf Technol 67:675–686

Yokoi H, Murata Y, Tsukakoshi H (1992) Measurement of melt temperature profiles during filling and packing processes using a new integrated thermocouple sensor. ANTEC 92–Shap Futur 2:1875–1881

Kazmer DO, Johnston SP, Gao RX, Fan Z (2011) Feasibility analysis of an in-mold multivariate sensor. Int Polym Process 26:63

Yang Y, Gao F (2006) Injection molding product weight: online prediction and control based on a nonlinear principal component regression model. Polym Eng Sci 46:540–548

Min B (2003) A study on quality monitoring of injection-molded parts. J Mater Process Technol 136:1–6

Richalet J (1993) Industrial applications of model based predictive control. Automatica 29:1251–1274

Kazmer DO, Westerdale S (2009) A model-based methodology for on-line quality control. Int J Adv Manuf Technol 42:280–292

Bicerano J (2002) Prediction of polymer properties: CRC Press, Boca Raton, IL

Wang Y, Xiao Y, Zhang Q, Gao XL, Fu Q (2003) The morphology and mechanical properties of dynamic packing injection molded PP/PS blends. Polymer 44:1469–1480

Kazmer D, Westerdale S, Hazen D (2008) A comparison of statistical process control (SPC) and on-line multivariate analyses (MVA) for injection molding. Int Polym Process 23:447–458

Fisches MK, Kazmer DO, Gordon GW (2003) Verification of rheological mixing rules to the application of masterbatches, presented at the Society of Plastics Engineers (SPE) ANTEC, Cincinnati, OH

Eastment H, Krzanowski W (1982) Cross-validatory choice of the number of components from a principal component analysis. Technometrics 24:73–77

Efron B, Gong G (1983) A leisurely look at the bootstrap, the jackknife, and cross-validation. Am Stat 37:36–48

Yokoi H, Masuda N, Mitsuhata H (2002) Visualization analysis of flow front behavior during filling process of injection mold cavity by two-axis tracking system. J Mater Process Technol 130:328–333

Gamberini R, Regattieri A (2008) Double pressing for porcelain stoneware tiles: an exploratory analysis. Ind Manag Data Syst 108:1081–1100

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gordon, G., Kazmer, D.O., Tang, X. et al. Quality control using a multivariate injection molding sensor. Int J Adv Manuf Technol 78, 1381–1391 (2015). https://doi.org/10.1007/s00170-014-6706-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6706-6