Abstract

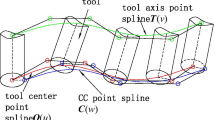

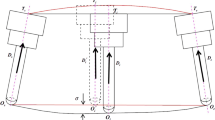

The aim of this study is to propose a five-axis toolpath smoothing method in order to improve the quality of machined surfaces. Currently, toolpaths are commonly computed from CAD models presenting small geometrical discontinuities. These discontinuities may be caused by an insufficient quality of the CAD model (geometrical discontinuities) and the use of meshed surfaces (e.g., stereolithography (STL) files). Normally, CAM systems generate linearly interpolated toolpaths. CNC options are then used on the machine to smooth the toolpath. The geometrical discontinuities of CAD models and linear toolpath interpolation may induce an unsmooth toolpath. This type of toolpath causes marks on the machined workpiece even if classical enhanced CNC options are used. Generally, these marks are unacceptable for the functionality of the workpiece. To reduce this problem, this study proposes a method to efficiently smooth toolpaths and consequently improve the obtained surface quality. The proposed method may be employed with high-end controllers commonly used on five-axis CNC machines. First, a five-degree polynomial interpolation method is presented. This interpolation is computed to ensure geometrical continuity in the slope and curvature of the obtained toolpath. Next, a concatenation method is proposed to reduce the size of the CNC program and to improve the toolpath smoothness. Moreover, the purpose of this concatenation is to obtain an optimized repartition of points along the toolpath. Furthermore, in a reverse engineering process, this method avoids surface reconstruction, decreasing the process time and improving the quality of the obtained surface. The efficiency of these methods is validated by the machining of biomedical prostheses. The CAD model used for the test is a meshed surface.

Similar content being viewed by others

References

Lim SP, Haroun H (2012) Surface reconstruction techniques: a review. Artif Intell Rev. doi:10.1007/s10462-012-9329-z

Park SC, Chung YC (2000) Tool-path generation from measured data. Comput Aided Des 35:467–475. doi:10.1016/S0010-4485(02)00070-2

Zhang Y, Ge L (2011) Adaptive tool-path generation on point-sampled surfaces. Precis Eng-J Int Soc 35:591–601. doi:10.1016/j.precisioneng.2011.04.002

Feng HY, Teng ZJ (2005) Iso-planar piecewise linear NC tool path generation from discrete measured data points. Comput Des 37:55–64. doi:10.1016/j.cad.2004.04.001

Chui KL, Chiu WK, Yu KM (2008) Direct 5-axis tool-path generation from point cloud input using 3D biarc fitting. Robot Comput Integr 24:270–286. doi:10.1016/j.rcim.2006.11.004

Sun YW, Guo DM, Jia ZY et al (2006) Iso-parametric tool path generation from triangular meshes for free-form surface machining. Int J Adv Manuf 28:721–726. doi:10.1007/s00170-004-2437-4

Park SC (2004) Sculptured surface machining using triangular mesh slicing. Comput Aided Des 36:279–288. doi:10.1016/S0010-4485(03)00114-3

Jun CS, Kim DS, Park SC (2002) A new curve-based approach to polyhedral machining. Comput Aided Des 34:379–389. doi:10.1016/S0010-4485(01)00110-5

Kim SJ, Yang MY (2006) A CL surface deformation approach for constant scallop height tool path generation from triangular mesh. Int J Adv Manuf Technol 28:314–320. doi:10.1007/s00170-004-2372-4

Lauwers B, Kiswanto G, Kruth JP (2003) Development of a five-axis milling tool path generation algorithm based on faceted models. CIRP Ann Manuf Technol 52(1):85–88. doi:10.1016/S0007-8506(07)60537-X

Lu J, Cheatham R, Jensen CG, Chen Y, Bowman B (2008) A three-dimensional configuration-space method for 5-axis tessellated surface machining. Int J Comput Integr Manuf 21(5):550–568. doi:10.1080/09511920701263313

Kiswanto G, Lauwers B, Kruth JP (2007) Gouging elimination through tool lifting in tool path generation for five-axis milling based on faceted models. Int J Adv Manuf Technol 32(3–4):293–309. doi:10.1007/s00170-005-0338-9

Lasemi A, Xue D, Gu P (2010) Recent development in NC machining of freeform surfaces: a state-of-the-art review. Comput Aided Des 42:641–651. doi:10.1016/j.cad.2010.04.002

Chaves-Jacob J, Linares JM, Sprauel JM (2011) Increasing of surface quality in friction free-form surfaces of knee prosthesis. CIRP Ann Manuf Tech 60:531–534. doi:10.1016/j.cirp.2011.03.059

Langeron JM, Duc E, Lartigue C, Bourdet P (2004) A new format for 5-axis tool path computation, using Bspline curves. Comput Aided Des 36:1219–1229. doi:10.1016/j.cad.2003.12.002

Lartigue C, Tournier C, Ritou M, Dumur D (2004) High-performance NC for HSM by means of polynomial trajectories. CIRP Ann Manuf Tech 53:317–320. doi:10.1016/S0007-8506(07)60706-9

Yong TH, Narayanaswami R (2003) A parametric interpolator with confined chord errors, acceleration and deceleration for NC machining. Comput Aided Des 35:1249–1259. doi:10.1016/S0010-4485(03)00043-5

Lavernhe S, Tournier C, Lartigue C (2008) Kinematical performance prediction in multi-axis machining for process planning optimization. Inte J Manuf Technol 37:534–544. doi:10.1007/s00170-007-1001-4

Vickers GW, Quan KW (1989) Ball-mills versus end-mills for curved surface machining. J Eng Ind Trans ASME 111(1):22–26. doi:10.1115/1.3188728

Huang YC, Oliver JH (1994) Non-constant parameter NC tool path generation on sculptured surfaces. Int J Adv Manuf Technol 9(5):281–290. doi:10.1007/BF01781282

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bouchenitfa, H., Chaves-Jacob, J., Linares, JM. et al. Improvement of toolpath quality combining polynomial interpolation with reduction of toolpath points. Int J Adv Manuf Technol 78, 875–883 (2015). https://doi.org/10.1007/s00170-014-6696-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6696-4