Abstract

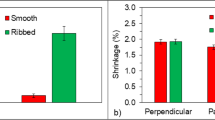

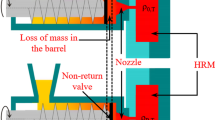

Due to the fact that different injection molding conditions tailor the mechanical response of the thermoplastic material, such effect must be considered earlier in the product development process. The existing approaches implemented in different commercial software solutions are very limited in their capabilities to estimate the influence of processing conditions on the mechanical properties. Thus, the accuracy of predictive simulations could be improved. In this study, we demonstrate how to establish straightforward processing-impact property relationships of talc-filled injection-molded polypropylene disc-shaped parts by assessing the thermomechanical environment (TME). To investigate the relationship between impact properties and the key operative variables (flow rate, melt and mold temperature, and holding pressure), the design of experiments approach was applied to systematically vary the TME of molded samples. The TME is characterized on computer flow simulation outputs and defined by two thermomechanical indices (TMI): the cooling index (CI; associated to the core features) and the thermo-stress index (TSI; related to the skin features). The TMI methodology coupled to an integrated simulation program has been developed as a tool to predict the impact response. The dynamic impact properties (peak force, peak energy, and puncture energy) were evaluated using instrumented falling weight impact tests and were all found to be similarly affected by the imposed TME. The most important molding parameters affecting the impact properties were found to be the processing temperatures (melt and mold). CI revealed greater importance for the impact response than TSI. The developed integrative tool provided truthful predictions for the envisaged impact properties.

Similar content being viewed by others

References

Ribeiro CJ, Viana JC (2011) Optimization of injection moulded polymer automotive components. In: Chiaberge M (ed) New trends and developments in automotive system engineering. InTech, Rijeka, pp 65–100

Viana JC (2006) Polymeric materials for impact and energy dissipation. Plast Rubber Compos 35:260–267. doi:10.1179/174328906X146522

Aretxabaleta L, Aurrekoetxea J, Urrutibeascoa I, Sanchez-Soto M (2005) Characterisation of the impact behaviour of polymer thermoplastics. Polym Test 24:145–151. doi:10.1016/j.polymertesting.2004.09.014

Perkins WG (1999) Polymer toughness and impact resistance. Polym Eng Sci 39:2445–2460. doi:10.1002/pen.11632

Aurrekoetxea J, Sarrionandia M, Urrutibeascoa I, Maspoch ML (2003) Effects of injection moulding induced morphology on the fracture behaviour of virgin and recycled polypropylene. Polymer 44:6959–6964. doi:10.1016/S0032-3861(03)00493-2

Sahin S, Yayla P (2005) Effects of processing parameters on the mechanical properties of polypropylene random copolymer. Polym Test 24:1012–1021. doi:10.1016/j.polymertesting.2005.07.010

Daiyan H, Andreassen E, Grytten F, Lyngstad OV, Luksepp T, Osnes H (2010) Low-velocity impact response of injection-moulded polypropylene plates—part 2: effects of moulding conditions, striker geometry, clamping, surface texture, weld line and paint. Polym Test 29:894–901. doi:10.1016/j.polymertesting.2010.06.001

Viana JC, Cunha AM, Billon N (2007) Experimental characterization and computational simulations of the impact behavior of injection-molded polymers. Polym Eng Sci 47:337–346. doi:10.1002/pen.20678

Barbosa CN, Viana JC, Franzen M, Simoes R (2012) Effect of the impact conditions on the mechanical properties of injection-molded parts. Polym Eng Sci 52:1845–1853. doi:10.1002/pen.23135

Kalay G, Bevis M (1997) Processing and physical property relationships in injection-molded isotactic polypropylene—part 1: mechanical properties. J Polym Sci B 35:241–263. doi:10.1002/(SICI)1099-0488(19970130)35:2<241::AID-POLB5>3.0.CO;2-V

Viana JC, Cunha AM (2002) The impact behavior of weld-lines in injection molding. J Inject Mold Technol 6:259–271

Kalay G, Bevis M (1997) Processing and physical property relationships in injection-molded isotactic polypropylene—part 2: morphology and crystallinity. J Polym Sci B 35:265–291. doi:10.1002/(SICI)1099-0488(19970130)35:2<265::AID-POLB6>3.0.CO;2-R

Mendoza R, Régnier G, Seiler W, Lebrun JL (2003) Spatial distribution of molecular orientation in injection molded iPP: influence of processing conditions. Polymer 44:3363–3373. doi:10.1016/S0032-3861(03)00253-2

Viana JC, Cunha AM, Billon N (2002) The thermomechanical environment and the microstructure of an injection moulded polypropylene copolymer. Polymer 43:4185–4196. doi:10.1016/S0032-3861(02)00253-7

Xu T, Yu J, Jin Z (2001) Effects of crystalline morphology on the impact behavior of polypropylene. Mater Des 22:27–31. doi:10.1016/S0261-3069(00)00033-9

Viana JC, Cunha AM, Billon N (2001) The effect of the skin thickness and spherulite size on the mechanical properties of injection mouldings. J Mater Sci 36:4411–4418. doi:10.1023/A:1017970416968

Meijer HE, Govaert LE (2005) Mechanical performance of polymer systems: the relation between structure and properties. Prog Polym Sci 30:915–938. doi:10.1016/j.progpolymsci.2005.06.009

Housmans J-W, Gahleitner M, Peters GW, Meijer HE (2009) Structure–property relations in molded, nucleated isotactic polypropylene. Polymer 50:2304–2319. doi:10.1016/j.polymer.2009.02.050

Godinho JS, Cunha AM, Crawford RJ (2000) Prediction of mechanical properties of polyethylene mouldings based on laminate theory and thermomechanical indices. Plast Rubber Compos 29:329–339. doi:10.1179/146580100101541139

Viana JC, Billon N, Cunha AM (2004) The thermomechanical environment and the mechanical properties of injection moldings. Polym Eng Sci 44:1522–1533. doi:10.1002/pen.20149

Cunha AM, Godinho JS, Viana JC (2000) Processing-structure properties relationships in injection moulded parts. In: Cunha AM, Fakirov S (eds) Structure development during polymer processing. Kluwer Academic Publishers, Dordrecht, pp 255–277

Barbosa CN, Simoes R, Franzen M, Viana JC (2013) Thermomechanical environment characterisation in injection moulding and its relation to the mechanical properties of talc-filled polypropylene. J Mater Sci 48:2597–2607. doi:10.1007/s10853-012-7052-4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barbosa, C.N., Carvalho, F., Viana, J.C. et al. Impact performance prediction of injection-molded talc-filled polypropylene through thermomechanical environment assessment. Int J Adv Manuf Technol 77, 873–883 (2015). https://doi.org/10.1007/s00170-014-6495-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6495-y