Abstract

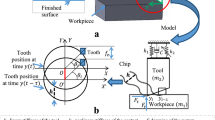

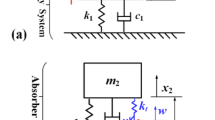

In the last years, different active methods and devices have been proposed to suppress chatter vibrations. Among active control devices, inertial actuators have demonstrated their good behaviour in several studies. However, their dimensioning and tuning are not clear issues. This work proposes the utilization of a novel coupled model, based on experimental data, where the cutting process and the effect of an active inertial device are simulated in time domain. In this way, the model permits to simulate different control strategies, control filters and actuators. The location of the actuator and the collocation or not of accelerometer can be taken into account, as well. In this work, the mathematical formulation of the model is developed, several applications are shown and, finally, its predictions are verified by means of real cutting operations.

Similar content being viewed by others

References

Tlusty J, Polacek M (1957) Beispiele der behandlung der selbsterregten Schwingung der Werkzeugmaschinen FoKoMa. Hanser Verlag, Munchen, Germany, pp 47–56

Tobias, SA, Fishwick, W (1958) Theory of regenerative machine tool chatter. The Engineer, 205

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Annals—Manufact Technol 40(1):357–362

Insperger T, Stepan G (2002) Semi-discretization method for delayed systems. Int J Numer Methods Eng 55(5):503–518

Liang XG, Yao ZQ, Luo L, Hu J (2013) An improved numerical integration method for predicting milling stability with varying time delay. Int J Adv Manuf Technol 68(9–12):1967–1976

Munoa, J, Zatarain, M, Dombovari, Z, Yang, Y (2009) Effect of mode interaction on stability of milling processes. Proceedings of the 12th CIRP Conference on Modelling of Machining Operations, San Sebastian, Spain.

Zatarain M, Bediaga I, Munoa J, Insperger T (2010) Analysis of directional factors in milling: importance of multi-frequency calculation and of the inclusion of the effect of the helix angle. Int J Adv Manuf Technol 47(5–8):535–542

Munoa J, Zatarain M, Bediaga I, Lizarralde R (2005) Optimization of hard material roughing by means of a stability model. 8th CIRP International Workshop on Modelling of Machining Operations, Chemnitz, Germany

Sims ND (2007) Vibration absorbers for chatter suppression: a new analytical tuning methodology. J Sound Vib 301:592–607

Yang Y, Munoa J, Altintas Y (2010) Optimization of multiple tuned mass dampers to suppress machine tool chatter. Int J of Mach Tools Manuf 50(9):834–852

Cowley A, Boyle A (1970) Active dampers for machine tools. CIRP Annals—Manuf Technol 18(1):213–222

Alter DM, Tsao TC (1994) Stability of turning processes with actively controlled linear motor feed drives. J Eng Ind–Trans of the ASME 116:298–307

Kamalzadeh A, Erkorkmaz K (2007) Compensation of axial vibrations in ball screw drives. CIRP Annals—Manuf Technol 56(1):373–378

Wong WWS, Erkorkmaz K (2010) Constrained identification of virtual CNC drives using a genetic algorithm. Int J Adv Manuf Technol 50(1–4):275–288

Trumper DL, Lu XD (2006) Fast tool servos: advance in precision, acceleration, and bandwidth. The 11th International Conference on Precision Engineering (ICPE), Tokyo, Japan

Knospe CR (2007) Active magnetic bearing for machining applications. Control Eng Pract 15(3):307–313

Tsai NC, Shih LW, Lee RM (2010) Spindle vibration suppression for advanced milling process by using self-tuning feedback control. Int J Adv Manuf Technol 48:1–10

Tsai NC, Lee RM (2011) Regulation of spindle position by magnetic actuator array. Int J Adv Manuf Technol 53:93–104

Uriarte L, Etxaniz I, Iturbe I (2012) Development of magnetically levitated high speed spindles and possibilities they give for the iteration with the milling process. 9th International Conference on Machine Tools, Automation, Technology and Robotics (MATAR), Prague, Czech Republic

Ehmann C, Nordmann R (2002) Low cost actuator for active damping of large machines. IFAC Conference on Mechatronic Systems, Berkeley, USA

Brecher C, Schulz A, Week M (2005) Electrohydraulic active damping system. CIRP Annals—Manuf Technol 54(1):389–392

Munoa J, Mancisidor I, Loix N, Uriarte LG, Barcena R, Zatarain M (2013) Chatter suppression in ram type travelling column milling machines using a biaxial inertial actuator. CIRP Annals–Manuf Technol 62:407–410

Sajedipour D, Behbahani S, Tabatabaei SMK (2010) Mechatronic modeling and control of a lathe machine equipped with a MR damper for chatter suppression. Proceedings of 8th IEEE International Conference on Control and Automation, Xiamen, China

Zaeh MF, Waibel M, Baur M (2009) A computational approach to the integration of adaptronic structures in machine tools. Comput Struct Eng. 1017–1028

Altintas Y (2012) Manufacturing automation, 2nd edn. Cambridge University Press, New York, USA

Iglesias A, Munoa J, Ciurana J (2014) Optimisation of face milling operations with structural chatter using a stability model based process planning methodology. Int J Adv Manuf Technol 70(1–4):559–571

Preumont A (2002) Vibration control of active structures: an introduction. 2nd ed. Kluwer Academic Publishers

Brecher C, Schulz A (2004) Active Auxiliary Mass Damper. Proceedings of ISMA 2004 International Conference on Noise and Vibration Engineering, Leuven, Belgium

Huyanan S, Sims ND (2007) Vibration control strategies for proof-mass actuators. J Vib Control 13(12):1785–1806

Albertelli P, Elmas S, Jackson MR, Bianchi G, Parkin RM, Monno M (2012) Active spindle system for a rotary planning machine. Int J Adv Manuf Technol 63:1021–1034

Bilbao-Guillerna A, Barrios A, Mancisidor I, Loix N, Munoa J (2010) Control laws for chatter suppression in milling using an inertial actuator. Proceedings of ISMA2010 International Conference on Noise and Vibration Engineering, Leuven, Belgium

Bilbao-Guillerna A, Azpeitia I, Luyckx S, Loix N, Munoa J (2012) Low frequency chatter suppression using an inertial actuator. 9th CIRP International Conference on High Speed Machining, San Sebastian, Spain

Ogata K (1995) Discrete-time control systems. Englewood Cliffs, NJ, Prentice-Hall

Mancisidor I, De la Fuente J, Barrios A, Barcena R, Muñoa J (2013) Diseño de un amortiguador activo para la eliminación de chatter en máquina herramienta. 19 Congreso de Máquinas-Herramienta y Tecnologías de Fabricación, San Sebastian, Spain

Vold H, Crowley J (1987) Polyreference modal parameter estimation from FRF’s with variable frequency spacing, The Fifth International Modal Analysis Conference

Stepan G, Dombovari Z, Munoa J (2011) Identification of cutting force characteristics based on chatter experiments. CIRP Annals – Manuf Technol 60:113–116

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mancisidor, I., Munoa, J., Barcena, R. et al. Coupled model for simulating active inertial actuators in milling processes. Int J Adv Manuf Technol 77, 581–595 (2015). https://doi.org/10.1007/s00170-014-6469-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6469-0