Abstract

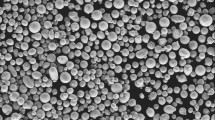

Additive manufacturing by selective laser melting (SLM) was used to investigate the effect of laser energy density on 316L stainless steel properties. Point distance and exposure time were varied and their impact on porosity, surface finish, microstructure, density and hardness, was evaluated. The surface roughness was primarily affected by point distance with increased point distance resulting in increased surface roughness, R a, from 10 to 16 μm. Material hardness reached a maximum of 225 HV at 125 J/mm3 and was related to the material porosity; with increased porosity leading to decreased material hardness. Different types of particle coalescence leading to convex surface features were observed (sometimes referred to as balling); from small ball features at low laser energy density to a mixture of both small and large ball features at high laser energy density. Laser energy density was shown to affect total porosity. The minimum amount of porosity, 0.38 %, was observed at an energy density of 104.52 J/mm3.

Similar content being viewed by others

References

Kruth J P, Badrossamay M, Yasa E, Deckers J, Thijs L, Humbeeck J V (2010) Part and material properties in selective laser melting of metals, in 16th International symposium on electromachining (ISEM XVI), doi: https://lirias.kuleuven.be/handle/123456789/265815

Paul BK, Baskaran S (1996) Issues in fabricating manufacturing tooling using powder-based additive freeform fabrication. J Mater Process Technol 61:168–172. doi:10.1016/0924-0136(96)02482-X

Hao L, Dadbakhsh S, Seaman O, Felstead M (2009) Selective laser melting of a stainless steel and hydroxyapatite composite for load-bearing implant development. J Mater Process Technol 209:5793–5801. doi:10.1016/j.jmatprotec.2009.06.012

Mathisen M B (2012) "In-situ tensile testing combined with EBSD analysis of Ti-6Al-4V samples from components fabricated by additive layer manufacture," Materials Science and Engineering, Submitted June 2012, doi: http://www.diva-portal.org/smash/record.jsf?pid=diva2:566362

Su X, Yang Y (2012) Research on track overlapping during selective laser melting of powders. J Mater Process Technol 212:2074–2079. doi:10.1016/j.jmatprotec.2012.05.012

Gebhardt A, Schmidt FM, Hotter JS, Sokalla W, Sokalla P (2010) "Additive manufacturing by selective laser melting the realizer desktop machine and its application for the dental industry," in Laser Assisted Net Shape Engineering 6, Proceedings of the LANE 2010, Part 2, doi: http://dx.doi.org/10.1016/j.phpro.2010.08.082

Chatterjee AN, Kumar S, Saha P, Mishra PK, Choudhury AR (2003) An experimental design approach to selective laser sintering of low carbon steel. J Mater Process Technol 136:151–157. doi:10.1016/S0924-0136(03)00132-8

Kruth JP, Froyen L, Vaerenbergh JV, Mercelis P, Rombouts M, Lauwers B (2004) Selective laser melting of iron-based powders. J Mater Process Technol 149:616–622. doi:10.1016/j.jmatprotec.2003.11.051

Wang Z, Guan K, Gao M, Li X, Chen X, Zeng X (2012) The microstructure and mechanical properties of deposited-IN718 by selective. J Alloys Compd 513:518–523. doi:10.1016/j.jallcom.2011.10.107

Mumtaz KA, Erasenthiran P, Hopkinson N (2008) High density selective laser melting of Waspaloy. J Mater Process Technol 195:77–87. doi:10.1016/j.jmatprotec.2007.04.117

Liu F, Lin X, Huang C, Song M, Yang G, Chen J, Huang W (2011) The effect of laser scanning path on microstructures and mechanical properties of laser solid formed nickel-base superalloy Inconel 718. J Alloys Compd 509(13):4505–4509. doi:10.1016/j.jallcom.2010.11.176

Simchi A (2006) Direct laser sintering of metal powders mechanism, kinetics and microstructural features. Mater Sci Eng A 428:148–158. doi:10.1016/j.msea.2006.04.117

Ekrami Y, Forth S C and Waid M C, "Characterization of electron beam free-form fabricated 2219 aluminum and 316 stainless steel", Technical Report, NASA, USRP, doi: http://ntrs.nasa.gov/search.jsp?R=20110008207

Yasa E, Kruth JP (2011) Microstructural investigation of selective laser melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng 19:389–395. doi:10.1016/j.proeng.2011.11.130

Gu D, Shen Y (2009) Balling phenomenon in direct laser sintering of stainless steel powder: metallurgical mechanisms and control methods. Mater Des 30:2903–2910. doi:10.1016/j.matdes.2009.01.013

Tolchko NK, Mozzharov SE, Yadroitsev IA, Laoui T, Froyen L, Titov VI, Ignatiev MB (2004) Balling process during selective laser treatment of powders. Rapid Prototyp J 10(2):78–87. doi:10.1108/13552540410526953

Körner C, Attar E, Heinl P (2011) Mesoscopic simulation of selective beam melting processes. J Mater Process Technol 211(6):978–987. doi:10.1016/j.jmatprotec.2010.12.016

Li Z, Mukai K, Zeze M, Mills KC (2005) Determination of the surface tension of liquid stainless steel. J Mater Sci 40:2191–2195. doi:10.1007/s10853-005-1931-x

Li R, Liu J, Shi Y, Wang L, Jiang W (2012) Balling behavior of stainless steel and nickel powder during selective laser melting process. Int J Adv Manuf Technol 59:1025–1035. doi:10.1007/s00170-011-3566-1

Khan M, Dickens P (2010) Selective laser melting (SLM) of pure gold. Gold Bull 43(2):114–121. doi:10.1007/BF03214976

Li R, Shi Y, Wang Z, Wang L, Liu J, Jiang W (2010) Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl Surf Sci 256:4350–4356. doi:10.1016/j.apsusc.2010.02.030

Simchi A (2008) Effect of C and Cu addition on the densification and microstructure of iron powder in direct laser sintering process. Mater Lett 62:2840–2843. doi:10.1016/j.matlet.2008.01.113

Campanelli SL, Contuzzi N, Angelastro A, Ludovico AD (2010) Capabilities and performances of the selective laser melting process, new trends in technologies: devices, computer, communication and industrial systems, M. J. Er, Ed., Open Access Book, DOI: http://www.intechopen.com/books/howtoreference/new-trends-in-technologies--devices--computer--communication-and-industrial-systems/capabilities-and-performances-of-the-selective-laser-melting-process

Taha MA, Yousef AF, Gany KA, Sabour HA (2012) On selective laser melting of ultra high carbon steel: effect of scan speed and post heat treatment. Mat wiss u werkstofftech 43(11):913–923. doi:10.1002/mawe.201200030

Zhang B, Coddet C (2012) Effects of processing parameters on properties of selective laser melting Mg–9%Al powder mixture. Mater Des 34:753–758. doi:10.1016/j.matdes.2011.06.061

Tolosa I, Garciandia F, Zapirain F, Zubiri F, Esnaola A (2010) Study of mechanical properties of AISI 316 stainless steel processed by "selective laser melting", following different manufacturing strategies. Int J Adv Manuf Technol 51:639–647. doi:10.1007/s00170-010-2631-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cherry, J.A., Davies, H.M., Mehmood, S. et al. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Technol 76, 869–879 (2015). https://doi.org/10.1007/s00170-014-6297-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6297-2