Abstract

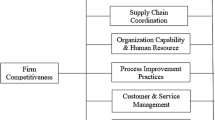

Manufacturing capability of a firm is given by the level of output generated by the production system employed which in turn decides the competitiveness in the market. The pattern of structural and infrastructural decisions in the manufacturing affects the capability of the production system. Therefore, it is crucial to know the overall manufacturing capability of a firm and the contribution of each decision in it. This paper presents quantification of manufacturing capability based on multi-criteria approach. A total of 33 decisions (criteria) and their corresponding choices have been identified from the literature analysis to quantify the manufacturing capability. These decisions are then classified into six decision areas (group criteria), and the manufacturing capability evaluation problem is modeled by using analytical hierarchy process (AHP) framework. The approach facilitates computation of manufacturing capability index by evaluating the decisions taken in the manufacturing, which is then mapped into four levels, namely, infant, industry average, adult, and world class as proposed by the Miltenburg. The methodology is illustrated with a numerical example for a job shop manufacturing system.

Similar content being viewed by others

References

Hayes RH, Wheelwright SC (1979) Link manufacturing process and product life cycles. Harv Bus Rev 57(1):133–140

Miltenburg J (2005) Manufacturing strategy—how to formulate and implement a winning plan, 2nd edn. Productivity Press, New York

Haas, E. A., (1987) Breakthrough manufacturing. Harv Bus Rev 75–81

Choudhari SC, Adil GK, Usha A (2012) Choices in manufacturing strategy decision areas in batch production system—six case studies. Int J Prod Res 50(14):3698–3717

Choudhari SC, Adil GK, Usha A (2012) Exploratory case studies on manufacturing decision areas in the job shop productions system. Int J Oper Prod Manag 32(11):1337–1361

Roy M, Platts KW (1997) Manufacturing vision and competitiveness. Integr Manuf Syst 8(5):313–322

Wheelwright, S. C. and Hayes, R. H., (1985). Competing through manufacturing. Harv Bus Rev 99–109

Vinod S, Balaji SR (2011) Fuzzy logic based leanness assessment and its decision support system. Int J Prod Res 49(13):4027–4041

Vinod S, Devadasan SR, Vasudeva Reddy B, Kusuma R (2010) Agility index measurement using multi-grade fuzzy approach integrated in a 20 criteria agile model. Int J Prod Res 48(23):7159–7176

Hallgren M, Olhager J (2006) Quantification of manufacturing strategy: a methodology and illustration. Int J Prod Econ 104:113–124

Skinner W (1969) Manufacturing—missing link in corporate strategy. Harv Bus Rev 47(3):136–145

Skinner W (1974) The focused factory. Harv Bus Rev 54(3):113–119

Santos FCA (2000) Integration of human resource management and competitive priorities of manufacturing strategy. Int J Oper Prod Manag 20(5):610–628

Hayes RH, Wheelwright SC (1984) Restoring our competitive edge: competing through manufacturing. Wiley, New York

Hill A, Hill T (2009) Manufacturing operations strategy. Palgrave Macmillan, Basingstoke, UK

Dangayach GS, Deshmukh SG (2001) Manufacturing strategy: literature review and some issues. Int J Oper Prod Manag 21(7):884–932

Leong K, Snyder D, Ward P (1990) Research in the process and content of manufacturing strategy. Omega 18(2):109–122

Giovani JC, Silveira DA (2005) Improving trade-offs in manufacturing: methods and illustration. Int J Prod Econ 95:27–38

Choudhari SC, Adil GK, Usha A (2010) Congruence of manufacturing decision areas in a production system: a research framework. Int J Prod Res 48(20):5963–5989

Miltenburg J (2008) Setting manufacturing strategy for factory within factory. Int J Prod Econ 113:307–323

Jayaram J, Cornelia D, Vickery SK (1999) The impact of human resource management practices on manufacturing performance. J Oper Manag 18:1–20

Slack N, Lewis M (2011) Operations strategy. Prentice Hall, UK

Safisadeh MH, Ritzman LP (1997) Linking performance drivers in production planning and inventory control to process choice. J Oper Manag 15(4):389–403

Kraljic P. (1983) Purchasing must become supply management. Harv Bus Rev 109–117

Vaidya OS, Sushil K (2006) Analytic hierarchy process: an overview of applications. CEJOR 169:1–29

Subramanian N, Ramanathan R (2012) A review of applications of analytic hierarchy process in operations management. Int J Prod Econ 138:215–241

Ho W, Xiaowei X, Dey PK (2010) Multi-criteria decision making approaches for supplier evaluation and selection: a literature review. Eur J Oper Res 202(1):16–24

Korpela J, Tuominen M (1996) Benchmarking logistics performance with an application of the analytic hierarchy process. IEEE Trans Eng Manag 43(3):323–333

Felix T, Chan S, Chan H, Henry K, Lau CW, Ralph WLIP (2006) An AHP approach in benchmarking logistics performance of the postal industry. Benchmarking: Int J 13(6):636–661

Partovi, Hopton (1994) The analytic hierarchy process as applied to the inventory types of inventory problem. Prod Invent Manag J 35:13–19

Khalid H, Zhang YB, Malak N (2002) Determining key capabilities of a firm using analytic hierarchy process. Int J Prod Econ 76:39–51

Akarte MM, Ravi B (2007) Casting product-process-producer compatibility evaluation and improvement. Int J Prod Res 45(21):4917–4936

Saaty TL (1990) How to make a decision: the analytic hierarchy process. Eur J Oper Res 48:9–26

Saaty TL (2008) Decision making with the analytic hierarchy process. Int J Services Sciences 1(1):83–98

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lekurwale, R.R., Akarte, M.M. & Raut, D.N. Framework to evaluate manufacturing capability using analytical hierarchy process. Int J Adv Manuf Technol 76, 565–576 (2015). https://doi.org/10.1007/s00170-014-6284-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6284-7