Abstract

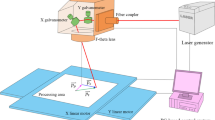

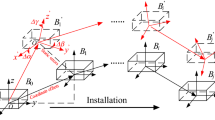

We have developed a one-axis on-the-fly system that can continuously process a large area by using a laser scanner. Existing laser processing using scanner systems can be used for precision processing, but have a limitation in the area of processing. To supplement this shortcoming, a step and scanning technique using a stage has been developed. This technique can process a large area in such a way that, after laser processing, the stage moves repetitively; however, this method has a demerit in that processing quality in the part between the scan areas is not even. To solve this problem, there is a method of synchronizing the scanner and the stage. This study developed an on-the-fly system that synchronizes the one-axis stage and the two-axis scanner. Also, in synchronized processing, the velocity of the stage due to the velocity of fabrication is very important. If the velocity of the stage is not proper, the laser processing deviates from the scanner work area. We proposed an algorithm in which, using a cell decomposition method, the velocity of the stage is automatically calculated by compensating for the acceleration/deceleration time occurring in the stage rotation and the reverse rotation due to the velocity of the fabrication. We compared the step and scanning method to the on-the-fly method through a low-frequency experiment and proved that the latter has better precision for the boundary of the scan area; we further analyzed the precision by using a large area marking and an overlapping experiment. In addition, by measuring encoder output signals, a compensation algorithm for the stage acceleration/deceleration time was verified.

Similar content being viewed by others

References

Zhang C, Salama IA, Quick NR, Kar A (2006) Modeling of microvia drilling with Nd:YAG laser. J Phys D: Appl Phys 39:3910–3918

Shin D, Lee J, Sohn H, Noh J, Paik B (2010) A FPCB cutting process using a pico-second laser. JLMN 5(1):48–52

Khan Malek CG (2006), vol 385

Kang HJ, Kim HJ, Kim JS, Choi WY, Chu WS, Ahn SH (2010) Laser marking system for light guide panel using design of experiment and web-based prototyping. Robotics and Computer-Integrated Manufacturing 26:535–540

Avanish KD, Vinod Y (2008) Experimental study of Nd:YAG laser beam machining—an overview. J Mater Process Technol 195:15–26

Borangiu T, Dogar A, Dumitrache A (2008) Constraints-based motion planning for an automatic, flexible laser scanning robotized platform, automation, quality and testing. Robotics 2:65–69

Kim KH, Yoon KH, Lee JH (2010) Path generation algorithm development for ultrafast/wide area laser processing. J KSPE 27(10):34–39

Iiguez, Rosell J (2003) Probabilistic harmonic-function-based method for robot motion planning. In: Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, pp 382–387

Lingelbach F (2004) Path planning using probabilistic cell decomposition. In: Proceedings of the IEEE International Conference on Robotics and Automation, pp 467–472

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoon, KH., Kim, KH. & Lee, JH. One-axis on-the-fly laser system development for wide-area fabrication using cell decomposition. Int J Adv Manuf Technol 75, 1681–1690 (2014). https://doi.org/10.1007/s00170-014-6267-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6267-8