Abstract

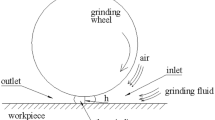

This research established a mathematical model of the useful grinding fluid flow rate of a rough grinding wheel. The abrasive distribution matrix of the grinding wheel surface topography was programmed on the MATLAB software platform to obtain the grinding wheel porosity φ at different particle sizes. The grinding fluid flow field was simulated and studied by using the volume of fluid multiphase flow model of FLUENT. Results showed that given a certain circular velocity of the grinding wheel, a larger grinding fluid jet velocity resulted in greater useful grinding fluid flow. When the grinding fluid jet velocity was set, the useful grinding fluid flow increased with increasing circular velocity of the grinding wheel. With the increasing velocity of the grinding wheel, as affected by the airbond layer, the increasing rate of the useful grinding fluid flow decreased, and the flow likewise showed a tendency to decrease. With a certain grinding fluid jet velocity, the useful flow rate of the grinding fluid was positively proportional to the useful flow. When the grinding fluid jet velocity changed and grinding wheel velocity was set, the grinding fluid jet velocity increased as the useful flow rate decreased. When the grinding fluid jet velocity was equivalent to the grinding wheel velocity, the useful flow rate of the grinding fluid was positively proportional to the useful flow. When the minimum clearance of grinding zone h increased, the useful grinding fluid flow and useful flow rate likewise increased. When the grinding fluid jet velocity was equivalent to the grinding wheel velocity, a larger nozzle gap width increased the flow supply for the grinding fluid and the useful grinding fluid flow. However, the increase in the useful flow rate of the grinding fluid was significantly smaller than that of the nozzle flow. This condition decreased the useful flow rate of the grinding fluid.

Similar content being viewed by others

References

Kopac J, Krajnik P (2006) High-performance grinding—a review. J Mater Process Technol 175(1–3):278–284

Jin T, Cai GQ (2001) Analytical thermal models of oblique moving heat source plane for deep grinding and cutting. J Manufact Sci Eng-ASME 123(1):185–90

Malkin S, Guo C (2007) Thermal analysis of grinding. CIRP Ann Manuf Technol 56(2):760–782

Brinksmeier E, Aurich JC, Govekar E (2006) Advances in modeling and simulation of grinding processes. CIRP Ann Manuf Technol 55(2):667–697

Ebbrell S, Woolley NH, Tridimas YD, Allanson DR, Rowe WB (2000) The effects of cutting fluid application methods on the grinding process. Int J Mach Tools Manuf 40(2):209–223

Bo Z, Akira N (2000) Hydrodynamic fluid pressure in grinding zone during grinding with metal-bonded diamond wheels. J Tribol 122:603–608

Frank C, Wojciech Z, Edwin F (2004) Fluid performance study for groove grinding a nickel-based Superalloy using electroplated cubic boron nitride (CBN) grinding wheels. J Manuf Sci Eng 126(3):451–458

Gao Y, Tse S, Mak H (2003) An active coolant cooling system for applications in surface grinding. Appl Therm Eng 23(5):523–537

Gviniashvili V, Webster J, Rowe B (2005) Fluid flow and pressure in the grinding wheel-workpiece interface. Trans ASME 127(1):198–205

Morgan MN, Jackson AR, Wu H, Baines-Jonesb V, Batakoa A, Rowe WB (2008) Optimisation of fluid application in grinding. CIRP Annals-Manuf Technol 57(1):363–366

Baheti U, Guo C, Malkin S (1998) Environmentally conscious cooling and lubrication for grinding. Proc Int Semin on Improv Mach Tool Perform Vol 2:643–654

Weinert K, Inasaki I, Sutherland JW (2004) Dry machining and minimum quantity lubrication. Annals of the CIRP 53(2):323–349

Donaldson K, Li XY, MacNee W (1998) Ultrafine (nanometer) particle mediated lung injury. J Aerosol Sci 29(5):553–60

Park K-H, Olortegui-Yume J, Yoon M-C (2010) A study on droplets and their distribution for minimum quantity lubrication (MQL). Int J Machine Tool Manuf 50(9):824–33

Kaliszer H, Trmal G (1975) Mechanics of grinding fluid delivery [J]. SME Tech. Paper

Campbell J D (1993) An investigation of the grinding fluid film boiling limitation. Technical papers-society of manufacturing engineers-all series 1993

Campbell J D (1995) Optimized coolant application. Technical papers- society of manufacturing engineers-all series 1995

Ganesan M, Guo C, Malkin S (1995) Measurement of hydrodynamic forces in grinding. Trans-North Am Manuf Res Inst SME 1995:103–108

Ganesan M, Guo C, Ronen A, Malkin, S. (1996) Analysis of hydrodynamic forces in grinding. Transactions-north American manufacturing research institution of SME (10/11): 6–12

Chang CC, Wang SH, Szeri AZ (1996) On the mechanism of fluid transport across the grinding zone. J Mech Des 118(3):332–338

Klocke F, Baus A, Beck T (2000) Coolant induced forces in CBN high speed grinding with shoe nozzles. CIRP Annals-Manuf Technol 49(1):241–244

Hryniewicz P, Szeri AZ, Jahanmir S (2001) Application of lubrication theory to fluid flow in grinding: part I-flow between smooth surfaces. J Tribol 123(1):94–100

Hryniewicz P, Szeri AZ, Jahanmir S (2001) Application of lubrication theory to fluid flow in grinding: part II-influence of wheel and workpiece roughness. J Tribol 123(1):101–107

Guo C, Malkin S (1992) Analysis of fluid flow through the grinding zone. J Eng Ind ASME 114(2):427–434

Engineer F, Guo C, Malkin S (1992) Experimental measurement of fluid flow through the grinding zone. J Eng Ind 114(4):61–66

Gviniashvili V, Webster J, Rowe B (2005) Fluid flow and pressure in the grinding wheel-workpiece interface. J Manuf Sci Eng 127(1):198–205

Gviniashvili V, Rowe WB, Morgan MN (2004) Useful flowrate based on grinding power. J Key Eng Mater 257–258:333–338

Gviniashvili VK, Woolley NH, Rowe WB (2004) Useful coolant flowrate in grinding. Int J Mach Tools Manuf 44(2):629–636

Li CH, Hou YL, Fang Z (2011) Analytical and experimental investigation of grinding fluid hydrodynamic pressure at wedge-shaped zone. Int J Abras Technol 4(2):140–155

Changhe L, Yali H, Guangqi XSC (2008) Model and simulation of slurry velocity and hydrodynamic pressure in abrasive jet finishing with grinding wheel as restraint. Key Eng Mater 375–376:449–453

Chang-he L, Guang-qi C, Shi-chao X (2007) Hydrodynamic pressure modeling and verification of contact zone on abrasive jet finishing with grinding wheel as restraint. Acta Armamentarii 28(2):202–205

Han ZL, Li CH (2013) Theoretical modeling and simulation of airflow field near grinding wheel. Int J Control Autom 6(4):145–155

Li CH, Han ZL (2013) Modeling and simulation of the airflow field in wedge-shaped zone during the high-speed grinding. Int J Abras Technol 6(2):114–131

Junyi Z, Nan L, Zhengfeng J (2009) Application study on two-phase flow field properties of grinding fluidic jet. Mach Tool Hydraul 37(1):20–23

Barczak LM, Batako ADL, Morgan MN (2010) A study of plane surface grinding under minimum quantity lubrication (MQL) conditions. Int J Mach Tools Manuf 50(11):977–985

Ramesh K, Huang H, Yin L (2004) Analytical and experimental investigation of coolant velocity in high speed grinding. Int J Mach Tools Manuf 44:1069–1076

Brinksmeier E, Minke E (1993) High-performance surface grinding—the influence of coolant on the abrasive process. Annals of the CIRP 42(1):367–370

Engineer F, Guo C, Malkin S (1992) Experimental measurement of fluid flow through the grinding zone. ASME J Eng Ind 114:61–66

Chang CC, Wang SH, Szeri AZ (1996) On the mechanism of fluid transport across the grinding zone. J Manuf Sci Eng Trans ASME 118(3):332–338

Chang CC, Wang SH, Szeri AZ (1996) On the mechanism of fluid transport across the grinding zone. J Manuf Sci Eng 118(8):332–338

Schumack MR, Jin-Bok C, Schultz WW (1991) Analysis of fluid flow under a gringing wheel. Transaction of the. ASME 113(5):190–197

Vladimir G, John W, Brian R (2005) Fluid flow and pressure in the grinding wheel-workpiece interface. Trans of the ASME 127(2):198–205

Chang CC (1997) An application of lubrication theory to predict useful flow-rate of coolant on grinding porous media. Tribol Int 30(8):575–581

Heinemann R, Hinduja S, Barrow G, Petuelli G (2006) Effect of MQL on the tool life of small twist drills in deep-hole drilling. Int J Mach Tools Manuf 46(1):1–6

Han ZL, Li CH (2013) Modelling and simulation of the airflow field in wedge-shaped zone during the high-speed grinding. Int J Abras Technol 6(2):114–131

Cong M, Hongfu Z, Xiangming H, Jian Z, Zhixiong Z (2013) The influence of spraying parameters on grinding performance for nanofluid minimum quantity lubrication. Int J Adv Manuf Technol 64(9–12):1791–1799

Dongzhou J, Li C, Li R (2014) Modeling and experimental investigation of the flow velocity field in the grinding zone. Int J Control Autom 7(2):405–416

Zhong ZW, Venkatesh VC (2009) Recent developments in grinding of advanced materials. Int J Adv Manuf Technol 41(5–6):468–480

Marius W, Wen L, Sami K, Christoph H (2014) Stepwise approach to reduce the costs and environmental impacts of grinding processes. Int J Adv Manuf Technol 71(5–8):919–931

Lin B, Morgan MN, Chen XW, Wang YK (2009) Study on the convection heat transfer coefficient of coolant and the maximum temperature in the grinding process. Int J Adv Manuf Technol 42(11–12):1175–1186

Hou ZB, Komanduri R (2003) On the mechanics of the grinding process–part I. Stochastic nature of the grinding process. Int J Mach Tools Manuf 43(15):1579–1593

Wang Sheng, Li Changhe, Zhang Dongkun, Jia Dongzhou, Zhang Yanbin (2014) Modeling the operation of a common grinding wheel with nanoparticle jet flow minimal quantity lubrication. Int J Adv Manuf Technol

Li CH, Liu ZR, Mao WP, Cai GQ (2010) Investigation of coolant fluid through grinding zone in high-speed precision grinding. J Donghua Univ (Engl Ed) 27(1):87–91

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Zhang, X., Zhang, Q. et al. Modeling and simulation of useful fluid flow rate in grinding. Int J Adv Manuf Technol 75, 1587–1604 (2014). https://doi.org/10.1007/s00170-014-6257-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6257-x