Abstract

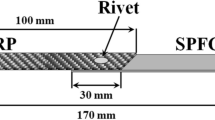

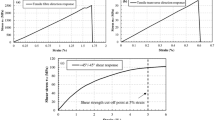

This paper focuses on the description of damage propagation around rivets in multiple joined single lap carbon fiber reinforced plastics (CFRP)-steel structures due to loads as a consequence of different coefficients of thermal expansion. Materials and rivets were chosen according to automotive body shop applications. Specimens were evaluated non-destructively in ultrasonic C-scans to characterize damage behavior of blind and self-piercing rivets in CFRP-steel-connections before and after the application of thermal loads. An algorithm for an automated detection of damage size on ultrasonic C-scan images was developed as the basis for further damage classification. The results show that blind riveting (BR) causes crack-like initial damage that broadens to roundish plane defects due to heating. Initial extensive damage due to self-piercing riveting (SPR) propagates in elliptic shape. Additionally, tension tests revealed a loss in ultimate load by 10–15 % induced by thermal loads and associated with damage propagation. A correlation between initial damage, relative displacement, and thermal loads was observed.

Similar content being viewed by others

References

ASTM D5961/D5961M Standard test method for bearing response of polymer matrix composite laminates

Barnes T, Pashby I (2000) Joining techniques for aluminium spaceframes used in automobiles. J Mater Process Technol 99(1–3):72–79. doi:10.1016/S0924-0136(99)00361-1

Barron TH (1998) Generalized theory of thermal expansion of solids. In: Ho C Y, Taylor R E (eds) Thermal expansion of solids, vol.4.ASM International,Materials Park and Ohio

Camanho P, Matthews F (1997) Stress analysis and strength prediction of mechanically fastened joints in frp: a review. Compos Part A 28(1):529–547

Chaplot SL, Mittal R, Choudhury N (2010) Thermodynamic properties of solids: Experiment and modeling. Wiley-VCH, Weinheim

Goswami S (2005) A finite element investigation on progressive failure analysis of composite bolted joints under thermal environment. J Reinforc Plast Compos 24(2):161–171. doi:10.1177/0731684405042958

Hahn O, Hufenbach W, Gude M, Kläger O (2004) Entwicklung eines auslegungskonzepts für geklebte und genietete cfk/al-karosseriestrukturen auf basis experimenteller und numerischer untersuchungen. In: Freundeskreis LWF Universität Paderborn e.V. (ed) In: Mechanisches Fügen und Kleben

Hart-Smith LJ (1987) Design and empirical analysis of bolted or riveted joints.In:Joining fibre-reinforced plastics. In: Matthews F L (ed) Joining fibre reinforced plastics. Elsevier Applied Science Publishers, Barking, pp 227–270

He X, Pearson I, Young K (2008) Self-pierce riveting for sheet materials: State of the art. J Mater Process Technol 199(1–3):27–36. doi:10.1016/j.jmatprotec.2007.10.071

Kim R, Whitney J (1976) Effect of temperature and moisture on pin bearing strength of composite laminates. J Compos Mat 10(2):149–155. doi:10.1177/002199837601000204

Kim YG, Lee DG (1998) Influence of fabrication residual thermal stresses on rubber-toughened adhesive tubular single lap steel-steel joints under tensile load. J Adhes 65(1–4):163–185. doi:10.1080/00218469808012244

Kim YG, Lee SJ, Lee DG, Jeong KS (1997) Strength analysis of adhesively-bonded tubular single lap steel-steel joints under axial loads considering residual thermal stresses. J Adhes 60(1–4):125–140. doi:10.1080/00218469708014414

Kochan A (2012) Untersuchungen zur zerstörungsfreien Prüfung von CFK-Bauteilen für die fertigungsbegleitende Qualitätssicherung im Automobilbau,Shaker,Aachen

Lee SJ, Lee DG (1995) Optimal design of the adhesively-bonded tubular single lap joint. J Adhes 50(2–3):165–180. doi:10.1080/00218469508014364

Persson E, Eriksson I, Zackrisson L (1997) Effects of hole machining defects on strength and fatigue life of composite laminates. Compos Part A 28(2):141–151. doi:10.1016/S1359-835X(96)00106-6

Reedy E, Guess T (1996) Butt joint strength: Effect of residual stress and stress relaxation. J Adhes Sci Technol 10(1):33–45. doi:10.1163/156856196X00436

Richter F (ed) (1974) Die wichtigsten physikalischen Eigenschaften von 52 Eisenwerkstoffen, vol. 5, 1 edn. Verlag Stahleisen, Düsseldorf. doi:10.1002/mawe.19740050419

Sadowski T, Kneć M, Golewski P (2010) Experimental investigations and numerical modelling of steel adhesive joints reinforced by rivets. Int J Adhes Adhes 30(5):338–346. doi:10.1016/j.ijadhadh.2009.11.004

Thoppul SD, Finegan J, Gibson RF (2009) Mechanics of mechanically fastened joints in polymer–matrix composite structures—a review. Compos Sci Technol 69(3–4):301–329. doi:10.1016/j.compscitech.2008.09.037

Tönshoff H, Kaak R, Christoph G, Mester O (1999) Festigkeitsverhalten blindgenieteter fvk/stahl-verbindungen. VDI-Z 10(9):58–60. http://www.vdi-z.de/vdi-z/article.php?data[article_id]=14398

Tsao C, Hocheng H (2005) Computerized tomography and c-scan for measuring delamination in the drilling of composite materials using various drills. Int J Mach Tool Manufact 45(11):1282–1287. doi:10.1016/j.ijmachtools.2005.01.009

Walker SP (2002) Thermal effects on the pin-bearing behavior of im7/peti5 composite joints. J Compos Mat 36(23):2623–2651. doi:10.1177/002199802761675557

Wilhelm M, Füssel U, Nancke T, Duschl M (2013) Herausforderung cfk-stahl-mischbau: Quantifizierung von delaminationen infolge des umformtechnischen fügens (06.-08.05). http://jt2013.dgzfp.de/

Wilhelm MF, Fuessel U, Richter T, Riemer M, Foerster M (2014) Analysis of the shear-out failure mode for cfrp connections joined by forming. Journal of Composite Materials

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wagner, J., Wilhelm, M., Baier, H. et al. Experimental analysis of damage propagation in riveted CFRP-steel structures by thermal loads. Int J Adv Manuf Technol 75, 1103–1113 (2014). https://doi.org/10.1007/s00170-014-6197-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6197-5