Abstract

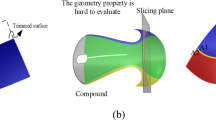

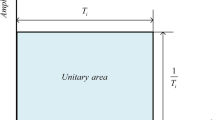

Free-form surfaces are used for many industrial applications from aeronautical parts, to molds or biomedical implants. In the common machining process, computer-aided manufacturing (CAM) software generates approximated tool paths because of the limitation induced by the input tool path format of the industrial CNC. Then, during the tool path interpolation, marks on finished surfaces can appear induced by non smooth feedrate planning. Managing the geometry of the tool path, as well as the kinematical parameters of the machine tool, are two key factors for quality and productivity improvements. The aim of this paper is to present a unified method to compute the trajectory directly on the surface to be machined avoiding CAM approximations and producing a smoother trajectory. This paper proposes an interpolation of the trajectory based on the free-form surface mathematical model while considering the kinematical limitations of a high-speed milling machine (velocity, acceleration, and jerk). The amelioration of the data exchange between computer-aided design (CAD)/CAM and CNC opens new ways to optimize the manufacturing process. The direct trajectory interpolation on the surface (DTIS) method allows to obtain both a higher productivity and a better surface quality. Machining experiments carried out with an Open CNC on a 5-axis high-speed milling machine show the benefits of the proposed method compared to the classical strategies available with an industrial CNC.

Similar content being viewed by others

References

LinuxCNC: Software for realtime control, (2014) http://www.linuxcnc.org, accessed June 2014

Beudaert X, Lavernhe S, Tournier C (2012) Feedrate interpolation with axis jerk constraints on 5-axis NURBS and G1 tool path. Int J Mach Tool Manu 57(0):73–82. doi:10.1016/j.ijmachtools.2012.02.005

Beudaert X, Lavernhe S, Tournier C (2013) 5-axis local corner rounding of linear tool path discontinuities. Int J Mach Tool Manu 73(0):9–16. doi:10.1016/j.ijmachtools.2013.05.008

Boujelbene M, Moisan A, Tounsi N, Brenier B (2004) Productivity enhancement in dies and molds manufacturing by the use of C1 continuous tool path. Int J Mach Tool Manu 44(1):101–107. doi:10.1016/j.ijmachtools.2003.08.005

Cheng CW, Tseng WP (2006) Design and implementation of a real-time NURBS surface interpolator. Int J Adv Manuf Tech 30(1-2):98–104. doi:10.1007/s00170-005-0021-1

Erkorkmaz K, Yeung CH, Altintas Y (2006) Virtual CNC system - Part II - High speed contouring application. Int J Mach Tool Manu 46(10):1124–1138. doi:10.1016/j.ijmachtools.2005.08.001

Erkorkmaz K, Layegh S E, Lazoglu I, Erdim H (2013) Feedrate optimization for freeform milling considering constraints from the feed drive system and process mechanics. CIRP Annals - Manufacturing Technology 62 (1):395–398. doi:10.1016/j.cirp.2013.03.084

Farouki RT, Manjunathaiah J, Yuan GF (1999) G codes for the specification of pythagorean-hodograph tool paths and associated feedrate functions on open-architecture CNC machines. Int J Mach Tool Manu 39(1):123–142. doi:10.1016/S0890-6955(98)00018-2

ISO (2004a) Industrial automation systems and integration - physical device control—data model for computerized numerical controllers—part 10: general process data. International Organization for Standardization ISO 14649-10

ISO (2004b) Industrial automation systems and integration - physical device control—data model for computerized numerical controllers—part 11: process data for milling. International Organization for Standardization ISO 14649-11

SEL K, Erdim H, Lazoglu I (2012) Offline force control and feedrate scheduling for complex free form surfaces in 5-axis milling. Procedia CIRP 1(0):96–101. doi:10.1016/j.procir.2012.04.015

Koren Y, Lin RS (1995) Five-axis surface interpolators. CIRP Ann-Manuf Techn 44(1):379–382. doi:10.1016/S0007-8506(07)62346-4

López de Lacalle L, Lamikiz A, Sánchez J, Salgado M (2004) Effects of tool deflection in the high-speed milling of inclined surfaces. Int J Adv Manuf Tech 24(9-10):621–631. doi:10.1007/s00170-003-1723-x

Lartigue C, Thiebaut F, Maekawa T (2001) CNC tool path in terms of B-spline curves. Comput Aided Design 33(4):307–319. doi:10.1016/S0010-4485(00)00090-7

Lartigue C, Tournier C, Ritou M, Dumur D (2004) High-performance NC for HSM by means of polynomial trajectories. CIRP Ann-Manuf Techn 53(1):317–320. doi:10.1016/S0007-8506(07)60706-9

Liang H, Li X (2013) Five-axis STEP-NC controller for machining of surfaces. Int J Adv Manuf Tech 68(9-12):2791–2800. doi:10.1007/s00170-013-4871-7

Lin RS (2000) Real-time surface interpolator for 3-D parametric surface machining on 3-axis machine tools. Int J Mach Tool Manu 40(10):1513–1526. doi:10.1016/S0890-6955(00)00002-X

Lo CC (2000) CNC machine tool surface interpolator for ball-end milling of free-form surfaces. Int J Mach Tool Manu 40(3):307–326. doi:10.1016/S0890-6955(99)00071-1

Omirou SL, Barouni AK (2005) Integration of new programming capabilities into a CNC milling system. Robot CIM-Int Manuf 21(6):518–527. doi:10.1016/j.rcim.2004.10.002

Otsuki T, Ogino H, Ide S, Chiba T (2004) Curve interpolation method. Japan, Fanuc LTD Yamanashi, (US Patent 6823234 B2)

Pateloup V, Duc E, Ray P (2010) B-spline approximation of circle arc and straight line for pocket machining. Comput Aided Design 42(9):817–827. doi:10.1016/j.cad.2010.05.003

Rauch M, Laguionie R, Hascoët JY, Suh SH (2012) An advanced STEP-NC controller for intelligent machining processes. Robot CIM-Int Manuf 28(3):375–384. doi:10.1016/j.rcim.2011.11.001

Siemens, Sinumerik (2009) 5 axis machining. Doc order no 6FC5095-0AB10-0BP1

de Souza AF, Coelho R (2007) Experimental investigation of feed rate limitations on high speed milling aimed at industrial applications. Int J Adv Manuf Tech 32(11–12):1104–1114. doi:10.1007/s00170-006-0445-2

Tsai MC, Cheng CW, Cheng MY (2003) A real-time NURBS surface interpolator for precision three-axis CNC machining. Int J Mach Tool Manu 43(12):1217–1227. doi:10.1016/S0890-6955(03)00154-8

Uhlmann E, Abackerli AJ, Schützer K, Lepikson HA, Helleno AL, Papa MCO, Conte EG, Mewis J (2014) Simulation and analysis of error impact on freeform surface milling. Int J Adv Manuf Technol 70(1–4):607–620. doi:10.1007/s00170-013-5280-7

Yang X (2002) Efficient circular arc interpolation based on active tolerance control. Comput Aided Design 34(13):1037–1046. doi:10.1016/S0010-4485(01)00164-6

Yutkowitz SJ, Chester W (2005) Apparatus and method for smooth cornering in a motion control system. Siemens Energy & Automation, Inc Alpharetta GA. (US Patent 6922606)

Zezhong CC, Maqsood KA (2014) A new approach to generating arc length parameterized NURBS tool paths for efficient three-axis machining of smooth, accurate sculptured surfaces. Int J Adv Manuf Tech 70(5-8):1355–1368. doi:10.1007/s00170-013-5411-1

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beudaert, X., Lavernhe, S. & Tournier, C. Direct trajectory interpolation on the surface using an open CNC. Int J Adv Manuf Technol 75, 535–546 (2014). https://doi.org/10.1007/s00170-014-6134-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6134-7