Abstract

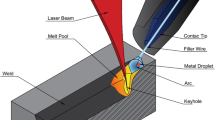

In this study, four welding methods, pulsed laser welding, defocused pulsed laser welding, laser–arc tandem welding, and laser–arc hybrid welding, were tested on 304 stainless steel sheets, and the differences between the weld cross-section outlines, especially the weld depth, were compared under different welding conditions. The author suggests that during the hybrid welding process, the upper part of the keyhole was surrounded by a large amount of melt such that the evaporation recoil pressure caused the gas–liquid interface to move towards the solid–liquid interface near weld pool surface. This flow behavior promoted both heat transfer from the central region of the weld pool to the solid–liquid interface near the weld pool surface, which resulted in an increased weld width, and increased the diameter of the upper part of the keyhole, which reduced the number of times the laser beam is reflected inside the keyhole and the coupling efficiency of laser energy. During pulse Nd:YAG laser–TIG arc tandem welding, there was a smaller amount of melt around the keyhole, which made it easier to form a U-shaped keyhole, which benefited the multiple reflection of laser beam in the keyhole and promoted the coupling of laser energy. The weld depths obtained from tandem welding and laser–arc hybrid welding were similar, which may be related to the difference in the keyhole shapes produced from the two welding processes.

Similar content being viewed by others

References

Steen WM (1980) Arc augmented laser processing of materials. J Appl Phys 51:5636–5641

Li CB, Liu LM (2013) Investigation on weldability of magnesium alloy thin sheet T-joints: arc welding, laser welding, and laser-arc hybrid welding. Int J Adv Manuf Technol 65:27–34

Casalino G, Campanelli SL, Ludovico AD (2013) Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int J Adv Manuf Technol 68:209–216

Chen YB, Feng JC, Li LQ, Li Y, Chang S (2013) Effects of welding positions on droplet transfer in CO2 laser–MAG hybrid welding. Int J Adv Manuf Technol 68:1351–1359

Campana G, Fortunato A, Ascari A, Tani G, Tomesani L (2007) The influence of arc transfer mode in hybrid laser-mig welding. J Mater Process Technol 191:111–113

Casalino G (2007) Statistical analysis of MIG-laser CO2 hybrid welding of Al-Mg alloy. J Mater Process Technol 191:106–110

Hu B, Richardson IM (2007) Microstructure and mechanical properties of AA7075(T6) hybrid laser/GMA welds. Mater Sci Eng A A459(1–2):94–100

Huang RS, Liu LM, Song G (2007) Infrared temperature measurement and interference analysis of magnesium alloys in hybrid laser-TIG welding process. Mater Sci Eng A 447(1–2):239–243

Liu LM, Wang JF, Song G (2004) Hybrid laser-TIG welding, laser beam welding and gas tungsten arc welding of AZ31B magnesium alloy. Mater Sci Eng A 381(1–2):129–133

Hu B, Den Ouden G (2005) Laser-induced stabilisation of the welding arc. Sci Technol Weld Join 10(1):76–81

Chen YB, Lei ZL, Wu L (2006) Experimental study on welding characteristics of CO2 laser TIG hybrid welding process. Sci Technol Weld Join 11(4):403–411

Hu B, den Ouden G (2005) Synergetic effects of hybrid laser/arc welding. Sci Technol Weld Join 10(4):427–431

Herbert S (2004) Laser-hybrid welding of ships. Weld J 83:39–43

Graf T, Staufer H (2003) Laser-hybrid welding drives VW improvements. Weld J 82:42–48

Defalco J (2007) Practical applications for hybrid laser welding. Weld J 86:47–51

Ribic B, Burgardt P, DebRoy T (2011) Optical emission spectroscopy of metal vapor dominated laser-arc hybrid welding plasma. J Appl Phys 109(8):083301

Liu LM, Hao XF (2008) Study of the effect of low-power pulse laser on arc plasma and magnesium alloy target in hybrid welding by spectral diagnosis technique. J Phys D Appl Phys 41(20):205202

Mahrle A, Schnick M, Rose S, Demuth C, Beyer E (2011) Process characteristics of fibre-laser-assisted plasma arc welding. J Phys D Appl Phys 44(34):345502

Qin GL, Lei Z, Lin SY (2007) Effects of Nd: YAG laser + pulsed MAG arc hybrid welding parameters on its weld shape. Sci Technol Weld Join 12(1):79–86

Kwon H, Baek WK, Kim MS, Shin WS, Yoh JJ (2012) Temperature-dependent absorptance of painted aluminum, stainless steel 304, and titanium for 1.07 μm and 10.6 μm laser beams. Opt Lasers Eng 50(2):114–121

Kaplan A (1994) A model of deep penetration laser welding based on calculation of the keyhole profile. J Phys D Appl Phys 27(9):1805–1814

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Gao, X., Sun, M. et al. Weld outline comparison between various pulsed Nd:YAG laser welding and pulsed Nd:YAG laser–TIG arc welding. Int J Adv Manuf Technol 75, 153–160 (2014). https://doi.org/10.1007/s00170-014-6122-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6122-y