Abstract

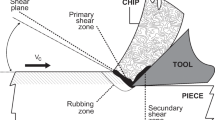

The present work is set to study the thermal contact phenomena in the tool–chip contact area, which affects the tool life and product quality in the machining process. The objective of this paper is to develop a reliable, efficient, and easy-to-use method for determining important and useful parameters required to study the thermal phenomena in the interface such as the thermal heat flux flowing into the cutting tool and the temperature distribution in the cutting tool. To estimate the heat flux, an inverse procedure is developed based on the sequential function specification (SFS) method. The thermocouples inserted into the specific locations of the cutting tool provide the inverse solver input data during the machining tests performed on AISI 1045 and AISI 304 steels. Future time regularisation method is used to reduce the errors caused by noise in the measured data. Temperature distribution in the tool is computed by performing transient thermal analysis using a 3D finite element model of the cutting tool. The effects of the machining parameters such as cutting speed and feed rate as well as the workpiece material properties on the thermal heat flux and tool temperature in the tool–chip interface are investigated and discussed considering the heat generation and propagation in the secondary deformation zone. The results of the research provide good insight into the effects of the machining parameters, workpiece properties, and tool surface quality on the thermal phenomena in the tool–chip interface.

Similar content being viewed by others

References

Iqbal SA, Mativenga PT, Sheikh MA (2007) Characterization of machining of AISI 1045 steel over a wide range of cutting speeds. Part 2: evaluation of flow stress models and interface friction distribution schemes. Proc Inst Mech Eng Part B J Eng Manuf 221:917–926. doi:10.1243/09544054JEM797

Molinari A, Cheriguene R, Miguelez H (2012) Contact variables and thermal effects at the tool–chip interface in orthogonal cutting. Int J Solids Struct 49:3774–3796. doi:10.1016/j.ijsolstr.2012.08.013

Pawade RS, Sonawane HA, Joshi SS (2009) An analytical model to predict specific shear energy in high-speed turning of Inconel 718. Int J Mach Tools Manuf 49:979–990. doi:10.1016/j.ijmachtools.2009.06.007

Ee K, Dillonjr O, Jawahir I (2005) Finite element modeling of residual stresses in machining induced by cutting using a tool with finite edge radius. Int J Mech Sci 47:1611–1628. doi:10.1016/j.ijmecsci.2005.06.001

Jam J, Norouzi Fard V (2011) A novel method to determine tool–chip thermal contact conductance in machining. IJEST 3:8491–8501

Filice L, Umbrello D, Beccari S, Micari F (2006) On the FE codes capability for tool temperature calculation in machining processes. J Mater Process Technol 174:286–292. doi:10.1016/j.jmatprotec.2006.01.012

Filice L, Micari F, Rizzuti S, Umbrello D (2007) A critical analysis on the friction modelling in orthogonal machining. Int J Mach Tools Manuf 47:709–714. doi:10.1016/j.ijmachtools.2006.05.007

Grzesik W (2006) Determination of temperature distribution in the cutting zone using hybrid analytical-FEM technique. Int J Mach Tools Manuf 46:651–658. doi:10.1016/j.ijmachtools.2005.07.009

Umbrello D, Filice L, Rizzuti S, Micari F (2007) On the evaluation of the global heat transfer coefficient in cutting. Int J Mach Tools Manuf 47:1738–1743. doi:10.1016/j.ijmachtools.2006.12.002

Ay H, Yang WJ (1998) Heat transfer and life of metal cutting tools in turning. Int J Heat Mass Transf 41:613–623

Ren X, Yang QX, James RD, Wang L (2004) Cutting temperatures in hard turning chromium hardfacings with PCBN tooling. J Mater Process Technol 147:38–44. doi:10.1016/j.jmatprotec.2003.10.013

Dour G, Dargusch M, Davidson C (2006) Recommendations and guidelines for the performance of accurate heat transfer measurements in rapid forming processes. Int J Heat Mass Transf 49:1773–1789. doi:10.1016/j.ijheatmasstransfer.2005.10.045

Dour G, Dargusch M, Davidson C, Nef A (2005) Development of a non-intrusive heat transfer coefficient gauge and its application to high pressure die casting: effect of the process parameters. J Mater Process Technol 169:223–233. doi:10.1016/j.jmatprotec.2005.03.026

Davies M, Ueda T, M’saoubi R et al (2007) On the measurement of temperature in material removal processes. CIRP Ann Technol 56:581–604. doi:10.1016/j.cirp.2007.10.009

Yen D, Wright P (1986) A remote temperature sensing technique for estimating the cutting interface temperature distribution. J Eng Ind (Trans ASME) 108:1986

Lin J (1995) Inverse estimation of the tool–work interface temperature in end milling. Int J Mach Tools Manuf 35:751–760

Kwon P, Schiemann T, Kountanya R (2001) An inverse estimation scheme to measure steady-state tool–chip interface temperatures using an infrared camera. Int J Mach Tools Manuf 41:1015–1030. doi:10.1016/S0890-6955(00)00113-9

Huang C-H, Jan L-C, Li R, Shih AJ (2007) A three-dimensional inverse problem in estimating the applied heat flux of a titanium drilling—theoretical and experimental studies. Int J Heat Mass Transf 50:3265–3277. doi:10.1016/j.ijheatmasstransfer.2007.01.031

Carvalho SR, Silva SLE (2006) Temperature determination at the chip–tool interface using an inverse thermal model considering the tool and tool holder. J Mater 179:97–104. doi:10.1016/j.jmatprotec.2006.03.086

Liang L, Xu H, Ke Z (2013) An improved three-dimensional inverse heat conduction procedure to determine the tool–chip interface temperature in dry turning. Int J Therm Sci 64:152–161. doi:10.1016/j.ijthermalsci.2012.08.012

Woodbury K (2003) Inverse engineering handbook. Press, CRC

Beck JV, Blackwell BF, St C (1985) Inverse heat conduction Ill-posed problems. Wiley Interscience, New York

Grzesik W, Nieslony P (2004) Prediction of friction and heat flow in machining incorporating thermophysical properties of the coating–chip interface. Wear 256:108–117. doi:10.1016/S0043-1648(03)00390-9

Grzesik W (2000) The influence of thin hard coatings on frictional behaviour in the orthogonal cutting process. Tribol Int 33:131–140. doi:10.1016/S0301-679X(00)00072-4

Courbon C, Mabrouki T, Rech J et al (2012) On the existence of a thermal contact resistance at the tool–chip interface in dry cutting of AISI 1045 : formation mechanisms and influence on the cutting process. Appl Therm Eng. doi:10.1016/j.applthermaleng.2012.06.047

Korkut I, Donertas MA (2007) The influence of feed rate and cutting speed on the cutting forces, surface roughness and tool–chip contact length during face milling. Mater Des 28:308–312. doi:10.1016/j.matdes.2005.06.002

Kilic DS, Raman S (2007) Observations of the tool–chip boundary conditions in turning of aluminum alloys. Wear 262:889–904. doi:10.1016/j.wear.2006.08.019

Grzesik W, Nieslony P (2003) A computational approach to evaluate temperature and heat partition in machining with multilayer coated tools. Int J Mach Tools Manuf 43:1311–1317. doi:10.1016/S0890-6955(03)00160-3

Grzesik W (1999) Experimental investigation of the influence of adhesion on the frictional conditions in the cutting process. Tribol Int 32:15–23. doi:10.1016/S0301-679X(99)00004-3

Singhal V, Litke P, Black A, Garimella S (2005) An experimentally validated thermo-mechanical model for the prediction of thermal contact conductance. Int J Heat Mass Transf 48:5446–5459. doi:10.1016/j.ijheatmasstransfer.2005.06.028

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Norouzifard, V., Hamedi, M. A three-dimensional heat conduction inverse procedure to investigate tool–chip thermal interaction in machining process. Int J Adv Manuf Technol 74, 1637–1648 (2014). https://doi.org/10.1007/s00170-014-6119-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6119-6