Abstract

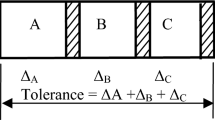

The quality of any product depends upon its component tolerance and assembly variations. Most products are composed of more than one component. These products require some type of assembly during production. Assembly is the process of joining two or more parts together. The functional performance of an assembled product and its manufacturing cost are directly affected by the individual component tolerances. However, tolerance is inevitable because manufacturing exactly equal parts is impossible. When the components are assembled together interchangeably, the assembly tolerance is the sum of the component tolerances. If the required assembly tolerance variation is less than the sum of the components’ tolerances, the rejection rate of assemblies will be more. In such cases, the selective assembly is the method to achieve tight assembly tolerance with the components manufactured at wider tolerances. This is accomplished by partitioning produced components into groups prior to random assembly. The mating components in the selective groups are then assembled at random. In this paper, artificial immune system (AIS) algorithm is developed to obtain the best combination of selective group with minimum variation in the assembly tolerance and least loss value within the specification range. The concept of Taguchi’s loss function is applied into the selective assembly method to evaluate the deviation from the mean. The selection of number of groups for selective assembly is also analyzed in this paper.

Similar content being viewed by others

References

Asha A, Kannan SM, Jayabalan V (2008) Optimization of clearance variation in selective assembly for components with multiple characteristics. Int J Adv Manuf Technol 38:1026–1044

Kannan SM, Asha A, Jayabalan V (2005) A new method in selective assembly to minimize clearance variation for a radial assembly using genetic algorithm. Qual Eng 17:595–607

Kannan SM, Jayabalan V, Jeevanantham K (2003) Genetic algorithm for minimizing assembly variation in selective assembly. Int J Prod Res 41(14):3301–3313

Kannan SM, Jayabalan V (2001) A new grouping method to minimize surplus parts in selective assembly for complex assemblies. Int J Prod Res 39(9):1851–1864

Kannan SM, Jayabalan V (2001) Selective assembly for minimizing assembly tolerance in linear assembly. 12th ISME Conference 420–425

Kannan SM, Jayabalan V (2001) A new grouping method for minimizing the surplus parts in selective assembly. Qual Eng 14(1):67–75

Chan KC, Linn RJ (1998) A grouping method for selective assembly of parts of dissimilar distributions. Qual Eng 11(2):221–234

Fang XD, Zhang Y (1995) A new algorithm for minimizing the surplus parts in selective assembly. Comput Ind Eng 28(2):341–350

Allen Pugh G (1992) Selective assembly with components of dissimilar variance. Comput Ind Eng 23:487–491

Shan HS, Satyawadi A (1989) Computer-aided component selection for precision assembling. 10th international conference on production research, University of Nottingham, UK, pp 734–739

Allen Pugh G (1986) Partitioning for selective assembly. Comput Ind Eng 11:175–179

Mansoor EM (1961) Selective assembly—its analysis and applications. Int J Prod Res 1(1):13–24

Kannan SM, Sivasubramanian R, Jayabalan V (2008) Particle swarm optimization for minimizing assembly variation in selective assembly. Int J Adv Manuf Technol 42:793–803

Ponnambalam SG, Saravana Sankar S, Sriram S, Gurumarimuthu M (2006) Parallel populations genetic algorithm for minimizing assembly variation in selective assembly. Proceeding of the 2006 I.E. International Conference on Automation Science and Engineering 496–500

Victor Raj M, Saravana Sankar S, Ponnambalam SG (2011) Optimization of assembly tolerance variations and manufacturing system efficiency by using genetic algorithm in batch selective assembly. Int J Adv Manuf Technol 55:1193–1208

Victor Raj M, Saravana Sankar S, Ponnambalam SG (2011) Maximising manufacturing system efficiency for multi-characteristic linear assembly by using particle swarm optimization in batch selective assembly. Int J Prod Res 49(21):6491–6516

Kern DC (2003) Forecasting manufacturing variation using historical process capability data: application for random assembly and serial processing. Dissertation, Massachusetts Institute of Technology, pp 137–188

Mease D, Sudjianto A, Nair VN (2004) Selective assembly in manufacturing: statistical issues and optimal binning strategies. Technometrics 46(2):165–175

Satheesh Kumar RM, Asokan P, Kumanan S (2009) Artificial immune system-based algorithm for the unidirectional loop layout problem in a flexible manufacturing system. Int J Adv Manuf Technol 40:553–565

Kannan SM, Jeevanantham AK, Jayabalan V (2008) Modelling and analysis of selective assembly using Taguchi’s loss function. Int J Prod Res 46(15):4309–4330

Taguchi G, Chowdhury S, Wu Y (2005) Taguchi’s quality engineering handbook. John Wiley and Sons, New Jersey

Engin O, Döyen A (2004) A new approach to solve hybrid flow shop scheduling problems by artificial immune system. Futur Gener Comput Syst 20:1083–1095

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Babu, J.R., Asha, A. Tolerance modelling in selective assembly for minimizing linear assembly tolerance variation and assembly cost by using Taguchi and AIS algorithm. Int J Adv Manuf Technol 75, 869–881 (2014). https://doi.org/10.1007/s00170-014-6097-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6097-8