Abstract

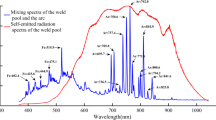

Thermal radiation of a weld pool contains plenty of welding quality information in a high-power fiber laser welding process, in which the weld pool width can reflect the welding stability. Thus, extracting the weld pool width characters of high-power fiber laser welding based on infrared imaging is an important method for monitoring the welding status. In this paper, the type 304 austenitic stainless steel is welded by a 10-kW high-power fiber laser continuously. A high-speed infrared video camera is employed to capture the infrared images of weld pools and their surroundings in the laser welding process. The infrared image characteristics of a weld pool are analyzed, and the improved homomorphic filtering algorithm based on Fourier transform is used to extract weld pool width which depends on the characteristic variation of weld pool images. And the comparison between improved homomorphic filtering algorithm and traditional homomorphic filtering algorithm is also discussed. Welding experimental results show that the proposed improved homomorphic filtering algorithm can extract the weld pool width and reflect the status of high-power fiber laser welding process accurately.

Similar content being viewed by others

References

Gao XD, Yong DY, Katayama S (2012) Seam tracking monitoring based on adaptive Kalman filter embedded Elman neural network during high-power fiber laser welding. IEEE Trans Ind Electron 59(11):4315–4325

Katayama S, Yousuke K, Masami M (2010) Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys Procedia 5:9–17

Gao XD, Mo L, Wen Q, Katayama S (2013) Neural network model for recognizing joint offset during fiber laser welding. Weld J 92(9):251–257

Katayama S, Kawahito Y (2008) Laser direct joining of metal and plastic. Scripta Mater 59(12):1247–1250

Çam G, Erim S, Yeni Ç, Koçak M (1999) Determination of mechanical and fracture properties of laser beam welded steel joints. Weld J 78(6):193s–201s

Çam G, Yeni Ç, Erim S, Ventzke V, Koçak M (1998) Investigation into properties of laser welded similar and dissimilar steel joints. Sci Technol Weld Join 3(4):177–189

Çam G, Koçak M (1998) Progress in joining of advanced materials—part I: solid state joining, fusion joining, and joining of intermetallics. Sci Technol Weld Join 3(3):105–126

Çam G, Koçak M (1998) Progress in joining of advanced materials. Int Mater Rev 43(1):1–44

Li ZY, Wang Y, Wang W, Wang XY (2010) Analysis on the interaction between laser and MIG plasma. Int J Appl Electrom 33:527–532

Chang CL, Chen YH (2005) Measurements of fillet weld by 3D laser scanning system. Int J Adv Manuf Technol 25(5–6):466–470

Gao XD, Mo L, Zhong XG, You DY, Katayama S (2011) Detection of seam tracking offset based on infrared image during high-power fiber laser welding. Acta Phys Sin 60(8):088105-1-8

Aurel VB, Cristian C, Alexandru P (2012) Pulsed LASER-(micro) TIG hybrid welding: process characteristics. J Mater Process Technol 212:890–902

Gao XD, Yong DY, Katayama S (2012) Infrared image recognition for seam tracking monitoring during fiber laser welding. Mechatronics 22(4):370–380

Gao XD, Wen Q (2013) Monitoring of high-power fiber laser welding based on principal component analysis of molten pool configuration. Laser Phys 23(12):126001–126009

Mitchell D, Gu F (2013) Autonomous weld seam identification and localization using eye-in-hand stereo vision for robotic arc welding. Robot Cim-Int Manuf 29(5):288–301

Fabrice B, Adolfo C, Jose MLH, Olivier C, Pascal A, Thierry D, Mats H, Per N, Peter J, Julian DCJ, Duncan PH (2005) Optical techniques for real-time penetration monitoring for laser welding. Appl Optics 44(19):3869–3876

Liu AH, Tang XH, Lu FG (2013) Weld pool profile characteristics of Al alloy in double-pulsed GMAW. Int J Adv Manuf Technol 68(9–12):2015–2023

Zhang ZF, Yu HW, Lv N, Chen SB (2013) Real-time defect detection in pulsed GTAW of Al alloys through on-line spectroscopy. J Mater Process Technol 213(7):1146–56

De A, Parle D (2003) Real time seam tracking system for automated fusion arc welding. Sci Technol Weld Join 8(5):340–346

Satoru A, Kushi T, Katsumi K, Tudaaki K, Kenichi N (1998) Development of fully automatic GMAW system with visual sensor. IIW Doc. XII - 1546, International Institute of Welding, Vienna 245–272

Middel W, Ouden GD (1999) Additive assisted through the arc sensing during gas tungsten arc welding. Sci Technol Weld Join 4:335–339

Kumar GS, Natarajan U, Ananthan SS (2012) Vision inspection system for the identification and classification of defects in MIG welding joints INT. J Adv Manuf Technol 61:923–933

Gao ZG, Wu YX, Huang J (2009) Analysis of weld pool dynamic during stationary laser—MIG hybrid welding. Int J Adv Manuf Technol 44(9–10):870–879

Takeshita K, Uchibori A, Mizukami Y, Satoh T, Tanaka K, Uchikado S (2003) A communication system for ALS patients using eye blink. Int J Appl Electrom 18:3–10

Matteï S, Grevey D, Mathieu A, Kirchner L (2009) Using infrared thermography in order to compare laser and hybrid (laser+MIG) welding processes. Opt Laser Technol 41:665–670

Shen HY, Wu J, Lin T, Chen SB (2008) Arc welding robot system with seam tracking and weld pool control based on passive vision. Int J Adv Manuf Technol 39(7–8):669–678

Li XC, Deng H, Li GQ (2012) Improved switching median filter for removing impulse noise from the image of the welded joint. 2012 5th INT. CISP 312–315

Chen B, He L, Liu P (2005) A morphological edge detector for gray-level image thresholding. LNCS 3656:659–666, ICIAR 2005

Yang WD, Guo W, Peng K, Liu LB (2012) Research on removing shadow in workpiece image based on homomorphic filtering. Procedia Eng 29:2360–2364

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Gao, X. Detection of weld pool width using infrared imaging during high-power fiber laser welding of type 304 austenitic stainless steel. Int J Adv Manuf Technol 74, 1247–1254 (2014). https://doi.org/10.1007/s00170-014-6081-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6081-3