Abstract

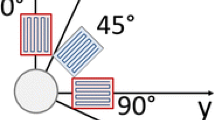

A major role in the process of quality assurance of cast parts is the analysis of porosities. In this paper, a method providing an evaluation technique of the available 3D data offered by the new computed tomography (CT) technology is developed, describing how the material’s strength at the location of the porosity gets attenuated. The steps in achieving this goal are as follows: First, the multitude of tensile testing results of porosity-afflicted samples at hand is to be studied giving rise for quantitative descriptions of the main influential factors of the material’s degradation, like the porosity shape, the position, the minimum radius, the distance to surface, etc. Then, the second step is to build up a numerical testing setup, facilitating to modify these parameters independently of each other utilizing characteristic porosity geometries. After validation of this model in regard of the known experimental results, at third, a design of experiments (DOE) has to be performed on it revealing the main dependencies of the shape’s properties on the stress concentration factors. Eventually, the applied approach is evaluated for prediction of fatigue life and fracture plane position of porous material.

Similar content being viewed by others

References

Campbell J (2003) Castings. Butterworth-Heinemann

Anson J, Gruzleski J (1999) The quantitative discrimination between shrinkage and gas microporosity in cast aluminum alloys using spatial data analysis. Mater Charact 43(5):319–335

Buffière J-Y et al (2001) Experimental study of porosity and its relation to fatigue mechanisms of model Al–Si7–Mg0.3 cast Al alloys. Mater Sci Eng A 316(1):115–126

Babout L et al (2003) Damage assessment in metallic structural materials using high resolution synchrotron X-ray tomography. Nucl Inst Methods Phys Res B Beam Interact Mater Atoms 200:303–307

Weiler J et al (2005) Relationship between internal porosity and fracture strength of die-cast magnesium AM60B alloy. Mater Sci Eng A 395(1):315–322

Ji S, Gu Q, Xia B (2006) Porosity dependence of mechanical properties of solid materials. J Mater Sci 41(6):1757–1768

Weiler J, Wood J (2009) Modeling fracture properties in a die-cast AM60B magnesium alloy II—the effects of the size and location of porosity determined using finite element simulations. Mater Sci Eng A 527(1):32–37

Vanderesse N et al (2011) Microtomographic study and finite element analysis of the porosity harmfulness in a cast aluminium alloy. Int J Fatigue 33(12):1514–1525

Shirani M, Härkegård G (2012) Damage tolerant design of cast components based on defects detected by 3D X-ray computed tomography. Int J Fatigue 41:188–198

Stephens RI, Fuchs HO (2001) Metal fatigue in engineering. Wiley, New York

Baumel A Jr, Seeger T (1990) Materials data for cyclic loading. Supplement 1. Elsevier Science Publishers, Amsterdam

Suresh S (1998) Fatigue of materials. Cambridge University Press, Cambridge

Wadell H (1935) Volume, shape, and roundness of quartz particles. J Geol 43:250–280

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amirirad, Y., Afkar, A. & Wisweh, L. Analysis of porosity-induced stress intensity factors for the evaluation of inline-computer tomography scans of cast parts. Int J Adv Manuf Technol 74, 1469–1485 (2014). https://doi.org/10.1007/s00170-014-6067-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6067-1