Abstract

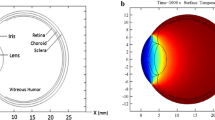

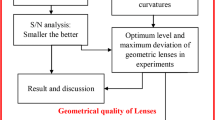

Residual stresses are important criteria for evaluating precision compression molded glass lenses. In this research, residual stresses inside a molded aspherical glass lens were investigated using both experimental and numerical methods. Specifically, residual stresses were calculated from optical measurements obtained by the use of a circular polariscope. From the measurements, both the magnitude and distribution of residual stresses in the aspherical glass lens were obtained. The residual stresses were also calculated using the structural relaxation model implemented in the finite element method software, and the results were compared to the measurements in experiments that were performed using matching molding conditions. In addition, residual stresses under different cooling rates were investigated in simulation and the impact of the cooling rate on the aspherical surface deviation was also discussed.

Similar content being viewed by others

References

Maschmeyer RO, Andrysick CA, Geyer TW et al (1983) Precision molded-glass optics. Appl Opt 22:2410–2412. doi:10.1364/AO.22.002410

Yi AY, Jain A (2005) Compression molding of aspherical glass lenses-a combined experimental and numerical analysis. J Am Ceram Soc 88:579–586. doi:10.1111/j.1551-2916.2005.00137.x

He P, Wang F, Li L et al (2011) Development of a low cost high precision fabrication process for glass hybrid aspherical diffractive lenses. J Opt 13:085703. doi:10.1088/2040-8978/13/8/085703

Li L, He P, Wang F et al (2011) A hybrid polymer-glass achromatic microlens array fabricated by compression molding. J Opt 13:055407. doi:10.1088/2040-8978/13/5/055407

Aben H, Guillemet C (1993) Photoelasticity of glass. Springer, New York

Chen Y, Yi AY, Su L et al (2008) Numerical simulation and experimental study of residual stresses in compression molding of precision glass optical components. J Manuf Sci Eng 130:051012–051021. doi:10.1115/1.2950062

Ito H, Arai M, Matsui Y, Itagaki D (2013) Experimental testing and FEM simulation for thermal imprinting of micro/nano glass-optical devices. J Non-Cryst Solids 362:246–254. doi:10.1016/j.jnoncrysol.2012.10.018

Doyle JF, Danyluk HT (1978) Integrated photoelasticity for axisymmetric problems. Exp Mech 18:215–220. doi:10.1007/BF02328416

Schupp D (1999) Optical tensor field tomography for the determination of 3D stress in photoelastic materials. 1st World Congress on Industrial Process Tomography. Buxton, Greater Manchester, UK, pp 494-501

Aben H, Ainola L, Anton J (2000) Integrated photoelasticity for nondestructive residual stress measurement in glass. Opt Laser Eng 33:49–64. doi:10.1016/S0143-8166 (00) 00018-X

Hammer H, Lionheart WRB (2005) Reconstruction of spatially inhomogeneous dielectric tensors through optical tomography. J Opt Soc Am A 22:250–255. doi:10.1364/JOSAA.22.000250

Wijerathne MLL, Oguni K, Hori M (2008) Stress field tomography based on 3D photoelasticity. J Mech Phys Solids 56:1065–1085. doi:10.1016/j.jmps.2007.06.004

Jain A (2006) Experimental study and numerical analysis of compression molding process for manufacturing precision aspherical glass lenses. Dissertation, The Ohio State University

Fujidie Co., (2003), Material: Cemented Carbide Alloys, http://www.fujidie.co.jp

Soules TF, Busbey RF, Rekhson SM et al (1987) Finite-element calculation of stresses in glass parts undergoing viscous relaxation. J Am Ceram Soc 70:90–95. doi:10.1111/j.1151-2916.1987.tb04935.x

Aben H, Ainola L, Errapart A (2010) Application of the Abel inversion in case of a tensor field. Inverse Probl Sci Eng 18:241. doi:10.1080/17415970903545124

Anton, Errapart A, Aben H, Ainola L (2008) A discrete algorithm of integrated photoelasticity for axisymmetric problems. Exp Mech 48:613–620. doi:10.1007/s11340-008-9121-9

Errapart A, Aben H, Ainola L, Anton J (2011) Photoelastic tomography for the measurement of thermal and residual stresses in glass. 9th International Congress on Thermal Stresses

Aben H, Errapart A (2007) A non-linear algorithm of photoelastic tomography for the axisymmetric problem. Exp Mech 47:821–830. doi:10.1007/s11340-007-9057-5

Ajovalasit A, Barone S, Petrucci G (1998) A method for reducing the influence of quarter-wave plate errors in phase stepping photoelasticity. J Strain Anal Eng Des 33:207–216. doi:10.1243/0309324981512922

Zhao W, Chen Y, Shen L, Yi AY (2009) Refractive index and dispersion variation in precision optical glass molding by computed tomography. Appl Opt 48:3588–3595. doi:10.1364/AO.48.003588

Hillar A, Ainola L, Anton J (1999) Half-fringe phase-stepping with separation of the principal stress directions. Proceedings of the Estonian Academy of Sciences, Engineering. pp 198-211

Su L, Wang F, He P et al (2014) An integrated solution for mold shape modification in precision glass molding to compensate refractive index change and geometric deviation. Opt Laser Eng 53:98–103. doi:10.1016/j.optlaseng.2013.08.016

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tao, B., He, P., Shen, L. et al. Quantitatively measurement and analysis of residual stresses in molded aspherical glass lenses. Int J Adv Manuf Technol 74, 1167–1174 (2014). https://doi.org/10.1007/s00170-014-6058-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6058-2