Abstract

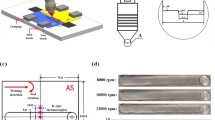

In order to study the effect of plastic deformation on the banded texture and flashes in friction stir welding process, a three-dimensional Lagrangian incremental finite element model was developed. The plastic deformation of friction stir welding and the forming and healing of transient keyhole during the welding process were studied visually by numerical simulation and validated by corresponding experiments. The simulation results were acceptably in good agreement with the experimental data. As shown in the numerical and experimental results, the flash of FSW joint which could be divided into two layers was mainly distributed on the retreating side. The forming and healing process of transient state keyhole includes outflow of weld materials from the beginning to 1/3 rotation period and backflow into the keyhole after 2/3 period. The distribution of plastic deformation was inhomogeneous upon the transverse cross-section, while the large deformation region was near the top surface and close to the advancing side.

Similar content being viewed by others

References

Thomas MW, Nicholas J, Needham JC, Much MG, Templesmith P, Dawes CJ (1995) Friction stir butt welding, GB Patent Application no. 9125978 · 8, 1991; US Patent no. 5460317, 1995

Balasubramanian N, Mishra RS, Krishnamurthy K (2011) Process forces during friction stir channeling in an aluminum alloy. J Mater Process Technol 211:305–311

Yan JH, Sutton MA, Reynolds AP (2005) Process-structure-property relationships for nugget and heat affected zone regions of AA2524-T351 friction stir welds. Sci Technol Weld Join 10(6):725–736

Sato YS, Takauchi H, Park SHC, Kokawa H (2005) Characteristics of the kissing-bond in friction stir welded Al alloy 1050. Mater Sci Eng A 405:333–338

Chen HB, Yan K, Lin T, Chen SB, Jiang CY, Zhao Y (2006) The investigation of typical welding defects for 5456 aluminum alloy friction stir welds. Mater Sci Eng A 433:64–69

Hamilton C, Dymek S, Blicharski M (2008) A model of material flow during friction stir welding. Mater Charact 59:1206–1214

Sutton MA, Yang BC, Reynolds AP, Yan JH (2004) Banded microstructure in 2024-T351 and 2524-T351 aluminum friction stir welds: Part II. Mechanical characterization. Mater Sci Eng A 364:66–74

da Silva AAM, Arruti E, Janeiro G, Aldanondo E, Alvarez P, Echeverria A (2011) Material flow and mechanical behaviour of dissimilar AA2024-T3 and AA7075-T6 aluminium alloys friction stir welds. Mater Des 32:2021–2027

Schmidt HNB, Dickerson TL, Hattel JH (2006) Material flow in butt friction stir welds in AA2024-T3. Acta Mater 54:1199–1209

Krishnan KN (2002) On the formation of onion rings in friction stir welds. Mater Sci Eng A 327:246–251

Fonda RW, Bingert JF (2007) Texture variations in an aluminum friction stir weld. Scr Mater 57:1052–1055

Neto DM, Neto P (2013) Numerical modeling of friction stir welding process: a literature review. Int J Adv Manuf Technol 65:115–126

Li JQ, Liu HJ (2013) Effects of welding speed on microstructures and mechanical properties of AA2219-T6 welded by the reverse dual-rotation friction stir welding. Int J Adv Manuf Technol 68:2071–2083

Fratini L, Buffa G, Micari F, Shivpuri R (2009) On the material flow in FSW of T-joints: influence of geometrical and technological parameters. Int J Adv Manuf Technol 44:570–578

Sutton MA, Yang B, Reynolds AP, Taylor R (2002) Microstructural studies of friction stir welds in 2024-T3 aluminum. Mater Sci Eng A 323:160–166

Sutton MA, Reynolds AP, Yang BC, Taylor R (2003) Mode I fracture and microstructure for 2024-T3 friction stir welds. Mater Sci Eng A 354:6–16

Xu SW, Deng XM (2008) A study of texture patterns in friction stir welds. Acta Mater 56:1326–1341

Chen ZW, Cui S (2008) On the forming mechanism of banded structures in aluminium alloy friction stir welds. Scr Mater 58:417–420

Cui GR, Ma ZY, Li SX (2008) Periodical plastic flow pattern in friction stir processed Al–Mg alloy. Scr Mater 58:1082–1085

Nandan R, Debroy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding-Process, weldment structure and properties. Prog Mater Sci 53:980–1023

Reynolds AP (2008) Flow visualization and simulation in FSW. Scr Mater 58:338–342

Xia TD, Peng FQ, Zhao WJ, Zhang ZH (2010) Study on dry tribological behavior of several deformed aluminum alloy against stainless steel. Mater Heat Treat 22:53–56

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, P., Guo, N., Chen, G. et al. Plastic deformation behavior of the friction stir welded AA2024 aluminum alloy. Int J Adv Manuf Technol 74, 673–679 (2014). https://doi.org/10.1007/s00170-014-6031-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6031-0