Abstract

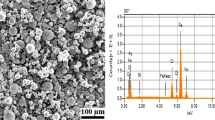

In this study, SUS316L is selected as an ideal material because of its easy workability and excellent corrosion resistance. The press equipment used in this study is a material testing system with a rated load of 25 t. Bipolar plates are manufactured, and their formabilities are evaluated according to various parameters (type of load, load size, die radius (R), and number of cycles) for dynamic load stamping. The bipolar plate formed using a sine-wave dynamic load (17 cycles, load of 50–120 kN) with a die radius of 0.3 mm has 15.0 % deeper channels than one formed with a static load of 120 kN. Moreover, when R is 0.1 mm, the bipolar plate formed using a square-wave dynamic load has 26 % deeper channels than one formed with a static load. Plates formed using sine-wave dynamic loads with R values of 0.1 and 0.3 mm have channel depths of 0.320 and 0.445 mm, respectively. Compared to an R value of 0.1 mm, the use of an R value of 0.3 mm produces channels that are 28 % deeper.

Similar content being viewed by others

References

Hamilton PJ, Pollet BG (2010) Polymer electrolyte membrane fuel cell (PEMFC) flow field plate: Design, materials and characterisation. Fuel Cells 10:489–509

Wang Y, Chen KS, Mishler J, Cho SC, Adroher XC (2011) A review of polymer electrolyte membrane fuel cells: Technology, applications, and needs on fundamental research. Appl Energy 88:981–1007

Mehta V, Cooper JS (2003) Review and analysis of PEM fuel cell design and manufacturing. J Power Sources 114:32–53

Wang H, Turner JA (2010) Reviewing metallic PEMFC bipolar plates. Fuel Cells 10:510–519

Middelman E, Kout W, Vogelaar B, Lenssen J, Waal E (2003) Bipolar plates for PEM fuel cells. J Power Sources 118:44–46

Dihrab SS, Sopian K, Alghoul MA, Sulaiman MY (2009) Review of the membrane and bipolar plates materials for conventional and unitized regenerative fuel cells. Renew Sustain Energy Rev 13:1663–1668

Hung JC, Yang TC, Li KC (2011) Studies on the fabrication of metallic bipolar plates-using micro electrical discharge machining milling. J Power Sources 196:2070–2074

Kwon HJ, Jeon YP, Kang CG (2013) Effect of progressive forming process and processing variables on the formability of aluminium bipolar plate with microchannel. Int J Adv Manuf Technol 64:681–694

Mahabunphachai S, Cora ÖN, Koç M (2010) Effect of manufacturing processes on formability and surface topography of proton exchange membrane fuel cell metallic bipolar plates. J Power Sources 195:5269–5277

Peng L, Lai X, Liu D, Hu P, Ni J (2008) Flow channel shape optimum design for hydroformed metal bipolar plate in PEM fuel cell. J Power Sources 178:223–230

Liu Y, Hua L (2010) Fabrication of metallic bipolar plate for proton exchange membrane fuel cells by rubber pad forming. J Power Sources 195:3529–3535

Jeong MG, Jin CK, Hwang GW, Kang CG (2014) Formability evaluation of stainless steel bipolar plate considering draft angle of die and process parameters by rubber forming. Int J Precis Eng Manuf 15:913–919

Jin CK, Jeong MG, Kang CG (2014) Fabrication of titanium bipolar plates by rubber forming and performance of single cell using TiN-coated titanium bipolar plates. Int J Hydrog Energy. doi:10.1016/j.ijhydene.2014.03.013

Lim SS, Kim YT, Kang CG (2013) Fabrication of aluminum 1050 micro-channel proton exchange membrane fuel cell bipolar plate using rubber-pad-forming process. Int J Adv Manuf Technol 65:231–238

Lee SJ, Chen YP, Huang CH (2005) Electroforming of metallic bipolar plates with micro-featured flow field. J Power Sources 145:369–375

Jin CK, Kang CG (2011) Fabrication process analysis and experimental verification for aluminum bipolar plates in fuel cells by vacuum die-casting. J Power Sources 196:8241–8249

Jin CK, Kang CG (2012) Fabrication by vacuum die casting and simulation of aluminum bipolar plates with micro-channels on both sides for proton exchange membrane (PEM) fuel cells. Int J Hydrog Energy 37:1661–1676

Jin CK, Jung MG, Kang CG (2014) Fabrication of aluminum bipolar plates by semi-solid forging process and performance test of TiN coated aluminum bipolar plates. Fuel Cells. doi:10.1002/fuce.201300137

Jin CK, Jang CH, Kang CG (2014) Effect of the process parameters on the formability, microstructure, and mechanical properties of thin plates fabricated by rheology forging process with electromagnetic stirring method. Metall Mater Trans B 45:193–211

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, MJ., Jin, CK. & Kang, C.G. Comparison of formabilities of stainless steel 316L bipolar plates using static and dynamic load stamping. Int J Adv Manuf Technol 75, 651–657 (2014). https://doi.org/10.1007/s00170-014-5986-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5986-1