Abstract

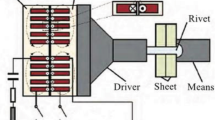

In this work, electromagnetic riveting (EMR) of aluminum alloy rivet was investigated by numerical simulation and experiments. The numerical simulation was carried out by means of ANSYS and LS-DYNA software. The SPHB (Split Hopkinson Pressure Bar) test was performed for 2A10 aluminum alloy rivets, and Johnson-Cook material model was used to describe it. The sequential electromagnetic-thermal-mechanical coupling model was established to analyze magnetic pressures, adiabatic temperature rise, and deformation process. Experiments and microstructure observation were performed to verify the proposed model. The formation of adiabatic shear band and the effective strain distribution were simulated, and the maximum temperature rise was up to 252 °C. The dynamic recrystallization was observed by optical microscopy observation under a discharging voltage of 2.0 kV. The simulation result of rivet heading accorded with experiments.

Similar content being viewed by others

References

Xu JR, Yu HP, Li CF, Lankarani H (2013) LI. Effects of process parameters on electromagnetic forming of AZ31 magnesium alloy sheets at room temperature. Int J Adv Manuf Technol 66:1591–1602

Cui XH, Mo JH, Xiao SH, Du EH (2011) LI. Numerical simulation of electromagnetic sheet bulging based on FEM. Int J Adv Manuf Technol 57:127–134

Wang LF, Chen ZY, Li CX, Huang SY (2006) LI. Numerical simulation of the electromagnetic of the electromagnetic sheet metal bulging process. Int J Adv Manuf Technol 30:395–400

Aman F, Cheraghi SH, Krishnan KK, Lankarani H (2013) Study of the impact of riveting sequence, rivet pitch, and gap between sheets on the quality of riveted lap joints using finite element method. Int J Adv Manuf Technol 67:545–562

Cheraghi SH (2008) Effect of variations in the riveting process on the quality of riveted joints. Int J Adv Manuf Technol 39:1144–1155

Meyers MA (1994) Dynamic behavior of materials. Wiley, New York, 298

Li YS, Tao NR, Lu K (2008) Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater 56:230–241

Xiao GH, Tao NR, Lu K (2009) Microstructures and mechanical properties of a Cu–Zn alloy subjected to cryogenic dynamic plastic deformation. Mater Sci Eng A 513–514:13–21

Xu F, Zhang XY, Ni HT (2013) Effect of twinning on microstructure and texture evolutions of pure Ti during dynamic plastic deformation. Mater Sci Eng A 564:22–33

Choo V, Reinhal PG, Ghassaei S (1989) Effect of high rate deformation induced precipitation hardening on the failure of aluminum rivets. J Mater Sci 24:59–60

Deng JH, Yu HP, Li CF (2009) Numerical and experimental investigation of electromagnetic riveting. Mater Sci Eng A 499:242–247

Cao ZQ (1999) Theory and application study on electromagnetic riveting: Ph.D. Dissertation of Northwestern Polytechnical University, 25–40

Yu HP, Deng JH, Li CF (2011) Effects of loading rate on TA1 rivet deformation in electromagnetic riveting. J Harbin Eng Univ 32:378–383

Andrade U, Meyers MA, Vecchio KS (1994) Dynamic recrystallization in high strain, high strain rate plastic deformation of copper. Acta Metall 42:3183–3195

Li Q, Xu YB, Lai ZH (1999) A model of dynamic recrystallization in alloys during high strain plastic deformation. J Mater Sci Technol 15:435–439

Xu F, Zhang XY, Cheng YM (2013) Study on adiabatic shear band in pure titanium subjected to dynamic plastic deformation. Rare Metal Mater Eng 42:801–804

Ge JF, Cao ZQ, Fan ZT, Sheng X (2005) Numerical simulation of electromagnetic riveting process. Forg Stamp Technol 6:62–65

Reinhal PG, Ghassaei S, Choo V (1988) An analysis of rivet die design in electromagnetic riveting. J Vib Acoust Stress Reliab Des 110:65–69

Zieve PB (1986) Low voltage electromagnetic riveter. Seattle: Ph. D. Dissertation of University of Washington

Oliveira DA, Worswick MJ, Finn M, Newmanc D (2005) Electromagnetic forming of aluminum alloy sheet: free-form and cavity fill experiments and model. J Mater Process Technol 170:350–362

QJ 782A-2005. General technical requirements for riveting

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming—a review. J Mater Process Technol 211:787–829

Deng JH (2008) Numerical and experimental investigation on electromagnetic riveting: Ph.D. Dissertation of Harbin Institute of Technology, 39–40

Cowper GR, Symonds PS (1957) Strain hardening and strain rate effect in the impact in the impact loading of cantilever beams. Brown University, Providence

Milani AS, Dabboussi W, Nemes JA, Abeyaratne RC (2009) An improved multi-objective identification of Johnson-Cook material parameters. Int J Impact Eng 36:294–302

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Yu, H.P. & Li, C.F. Multi-filed coupling numerical simulation and experimental investigation in electromagnetic riveting. Int J Adv Manuf Technol 73, 1751–1763 (2014). https://doi.org/10.1007/s00170-014-5983-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5983-4