Abstract

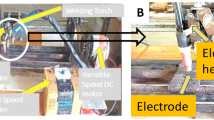

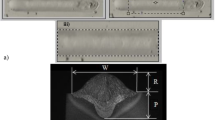

In this work, the oscillating arc narrow gap all-position gas metal arc (GMA) welding process was developed to improve efficiency and quality in the welding of thick-walled pipes. The statistical models of narrow gap all-position GMA weld bead geometry were developed using response surface methodology (RSM) based on central composite design (CCD). The developed models were checked for their adequacy and significance by ANOVA, and the effects of wire feed rate, travel speed, dwell time, oscillating amplitude and welding position on weld bead dimension were studied. Finally, the optimal welding parameters at welding positions of 0° to 180° were obtained by numerical optimization using RSM.

Similar content being viewed by others

References

Christensen KH, Sørensen T, Kristensen J (2005) Gas metal arc welding of butt joint with varying gap width based on neural networks. Sci Technol Weld Join 10(1):32–43. doi:10.1179/174329305X19303

Malin VY (1983) State-of-the-art of narrow gap welding. Weld J 62(Compendex):22–30

Wang JY, Ren YS, Yang F, Guo HB (2007) Novel rotation arc system for narrow gap MAG welding. Sci Technol Weld Join 12(6):505–507. doi:10.1179/174329307x213756

Murakami S, Kitagawa A, Nakajima H, Nagai A, Yonezawa M (1986) A study on horizontal narrow gap welding for heavy plates. Hitachi Zosen Technol Rev 47(1):33–38

Hirakoso K, Kano M, Nomura K (1980) Welding apparatus with shifting magnetic field. U.S Patent 4190760 A, 26 Feb

Guo N, Lin SB, Gao C, Fan CL, Yang CL (2009) Study on elimination of interlayer defects in horizontal joints made by rotating arc narrow gap welding. Sci Technol Weld Join 14(6):584. doi:10.1179/136217109X456942

Min D, Xin-hua T, Feng-gui L, Shun Y (2010) Welding of quenched and tempered steels with high-spin arc narrow gap MAG system. Int J Adv Manuf Technol 55(5–8):527–533. doi:10.1007/s00170-010-3052-1

Wang J, Zhu J, Fu P, Su R, Han W, Yang F (2012) A swing arc system for narrow gap GMA welding. Isij Int 52(1):110–114

Xu WH, Lin SB, Fan CL, Yang CL (2012) Feasibility study on tandem narrow gap GMAW of 65 mm thick steel plate. China Weld 21(3):7–11

Lassaline E, Zajaczkowski B, North TH (1989) Narrow groove twin-wire GMAW of high-strength steel. Weld J 68(9):53–58

Manonmani K, Murugan N, Buvanasekaran G (2007) Effects of process parameters on the bead geometry of laser beam butt welded stainless steel sheets. Int J Adv Manuf Technol 32(11–12):1125–1133. doi:10.1007/s00170-006-0432-7

Kim IS, Basu A, Siores E (1996) Mathematical models for control of weld bead penetration in the GMAW process. Int J Adv Manuf Technol 12(6):393–401. doi:10.1007/BF01186927

Gunaraj V, Murugan N (1999) Application of response surface methodology for predicting weld bead quality in submerged arc welding of pipes. J Mater Process Technol 88(1):266–275. doi:10.1016/S0924-0136(98)00405-1

Koleva E (2005) Electron beam weld parameters and thermal efficiency improvement. Vacuum 77(4):413–421. doi:10.1016/j.vacuum.2004.09.002

Starling C, Marques PV, Modenesi PJ (1995) Statistical modelling of narrow-gap GTA welding with magnetic arc oscillation. J Mater Process Technol 51(1):37–49. doi:10.1016/0924-0136(94)01356-6

Kim J, Kim I, Lee J, Jung S (2011) An experimental study on the prediction of back-bead geometry in pipeline using the GMA welding process. Int Sci J 49(1):53–61

Badkar DS, Pandey KS, Buvanashekaran G (2012) Application of the central composite design in optimization of laser transformation hardening parameters of commercially pure titanium using Nd:YAG laser. Int J Adv Manuf Technol 59(1–4):169–192. doi:10.1007/s00170-011-3492-2

Ii EJL, Torres GCF, Felizardo I, Filho FAR, Bracarense AQ (2005) Development of a robot for orbital welding. Ind Robot: Int J 32(4):321–325. doi:10.1108/01439910510600182

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, W.H., Lin, S.B., Fan, C.L. et al. Statistical modelling of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int J Adv Manuf Technol 72, 1705–1716 (2014). https://doi.org/10.1007/s00170-014-5799-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5799-2