Abstract

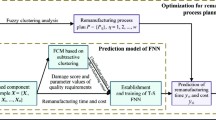

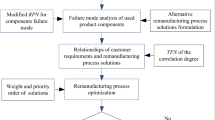

Remanufacturing represents an activity that often offers significant profit opportunities and can provide substantial environmental benefits. Process plan selection is one of the most important operational decisions in remanufacturing because it directly affects the success rate of remanufacturing as well as cost and quality. There is a need for a decision-making aid which can optimize process plan selection in the presence of wide-ranging alternatives. In response to this need, a decision method has been developed that combines the strengths of quality function deployment (QFD) and fuzzy linear regression. In this method, quality function deployment is employed to not only frame the problem but also to establish relationships between remanufacturing performance and process quality characteristics of interest. Fuzzy linear regression is used to determine the functional relationships between remanufacturing performance and process quality characteristics and obtain the optimal solution. If desired, the most suitable process plan alternative may be determined. To assess the usefulness and practicality of the proposed method, an illustrative example is given and the results are discussed.

Similar content being viewed by others

References

Karamouzian A, Teimoury E, Modarres M (2011) A model for admission control of returned products in a remanufacturing facility using queuing theory. Int J Adv Manuf Technol 54:403–412

Mukherjee K, Mondal S (2009) Analysis of issues relating to remanufacturing technology—a case of an Indian company. Tech Anal Strat Manag 21:639–642

Hatcher GD, Ijomah WL, Windmill JFC (2011) Design for remanufacture: a literature review and future research needs. J Clean Prod 19(17–18):2004–2014

Ortegon K, Nies LF, Sutherland JW (2013) Preparing for end of service life of wind turbines. J Clean Prod 39(1):191–199

Chen M, Abrishami P (2014) A mathematical model for production planning in hybrid manufacturing-remanufacturing systems. Int J Adv Manuf Technol:1–10

Zhang XG, Zhang H, Jiang ZG (2013) A decision-making approach for end-of-life strategies selection of used parts. Int J Adv Manuf Technol:1–8

Gao J, Chen X, Yilmaz O, Gindy N (2008) An integrated adaptive repair solution for complex aerospace components through geometry reconstruction. Int J Adv Manuf Technol 36(11–12):1170–1179

Andrew-Munot M, Ibrahim RN (2012) Development and analysis of mathematical and simulation models of decision-making tools for remanufacturing. Prod Plan Control (ahead-of-print):1–20

Zikopoulos C, Tagaras G (2007) Impact of uncertainty in the quality of returns on the profitability of a single-period refurbishing operation. Eur J Oper Res 182(1):205–225

Denizel M, Ferguson M, Souza G (2010) Multiperiod remanufacturing planning with uncertain quality of inputs. IEEE Trans Eng Manag 57(3):394–404

Tang XF, Mao HJ, Li XH (2011) Effect of quality uncertainty of parts on performance of reprocessing system in remanufacturing environment. J Southeast Univ 27(1):92–95

Aksoy HK, Gupta SM (2011) Optimal management of remanufacturing systems with server vacations. Int J Adv Manuf Technol 54:1199–1218

Li CB, Tang Y (2011) A GERT-based analytical method for remanufacturing process routing. 2011 I.E. International Conference on Automation Science and Engineering Trieste, Italy, August 24–27

Seliger G, Franke C, Ciupek M, Basdere B (2004) Process and facility planning for mobile phone remanufacturing. Ann CIRP 53(1):9–12

Kernbaum S, Heyer S, Chiotellis S, Seliger G (2009) Process planning for IT-equipment remanufacturing. CIRP J Manuf Sci Technol 2(1):13–20

Cao HJ, Wang BT, Liu F, Ma JQ (2010) Two-phase decision making strategy for remanufacturing process planning. Comput Integr Manuf Syst 16(5):935–941

Song C, Guan XH, Zhao QC, Jia QS (2011) Remanufacturing planning based on constrained ordinal optimization. Front Electr Electron Eng China 6(3):443–452

Li CB, Tang Y, Li CC, Li LL (2013) A modeling approach to analyze variability of remanufacturing process routing. IEEE Trans Autom Sci Eng 10(1):86–98

Govindan K, Sarkis J, Palaniappan M (2013) An analytic network process-based multicriteria decision making model for a reverse supply chain. Int J Adv Manuf Technol:1–18

Jiang ZG, Zhang H, Sutherland JW (2011) Development of multi-criteria decision making model for remanufacturing technology portfolio selection. J Clean Prod 19:1939–1945

Ke QD, Zhang HC, Liu GF, Li BB (2011) Remanufacturing engineering literature overview and future research needs. In: Hesselbach J, Herrmann C (eds) Globalized solutions for sustainability in manufacturing. Springer, Berlin, pp 437–442

Chan LK, Wu ML (2005) A systematic approach to quality function deployment with a full illustrative example. Omega 33(2):119–139

Tanaka H, Uejima S, Asai K (1982) Linear regression analysis with fuzzy model. IEEE Trans Syst Man Cybern 12:903–907

Tanaka H, Watada J (1988) Possibilistic linear systems and their application to the linear regression model. Fuzzy Sets Syst 27:275–289

Alptekin SE, Karsak EE (2011) An integrated decision framework for evaluating and selecting e-learning products. Appl Soft Comput 11(3):2990–2998

Du YB, Cao HJ, Chen X, Wang BT (2013) Reuse-oriented redesign method of used products based on axiomatic design theory and QFD. J Clean Prod 39:79–86

Jiang ZG, Zhang H, Sutherland JW (2012) Development of an environmental performance assessment method for manufacturing process plans. Int J Adv Manuf Technol 58:783–790

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Z., Fan, Z., Sutherland, J.W. et al. Development of an optimal method for remanufacturing process plan selection. Int J Adv Manuf Technol 72, 1551–1558 (2014). https://doi.org/10.1007/s00170-014-5783-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5783-x