Abstract

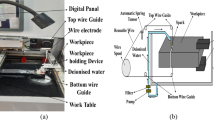

Aluminium metal matrix composites (MMCs) reinforced with silicon carbide particulate (SiCp) find several applications due to their improved mechanical properties over the conventional metals for a wide variety of aerospace and automotive applications. However, the presence of discontinuously distributed hard ceramic in the MMCs made them as difficult-to-cut materials for conventional machining methods. The wire electrical discharge machining (WEDM), as a widely adopted non-traditional machining method for difficult-to-cut precision components, found an appropriate metal removal process for MMCs to enhance quality of cut within the stipulated cost. While machining the advanced materials like MMCs, a clear understanding into the machining performance of the process for its control variables could make the process uncomplicated and economical. In light of the growing industrial need of making high performance-low cost components, the investigation aimed to explore the machining performance characteristics of SiCp reinforced Al7075 matrix composites (Al7075/SiCp) during WEDM. While conducting the machining experiments, surface roughness, metal removal rate, and wire wear ratio are considered the responses to evaluate the WEDM performance. Response surface methodology is used to develop the empirical models for these WEDM responses. SiC particulate size and volume percentages are considered the process variables along with pulse-on time, pulse-off time, and wire tension. Analysis of variance (ANOVA) is used to check the adequacy of the developed models. Since the machining responses are conflicting in nature, the problem is formulated as a multi-objective optimization problem and is solved using the Non-dominated Sorting Genetic Algorithm-II to obtain the set of Pareto-optimal solutions. The derived optimal process responses are confirmed by the experimental validation tests, and the results are analyzed by SEM.

Similar content being viewed by others

References

Sikder S, Kishawy HA (2012) Analytical model for force prediction when machining metal matrix composite. Int J Mech Sci 59:95–103

Li X, Seah WKH (2001) Tool wear acceleration in relation to workpiece reinforcement percentage in cutting of metal matrix composites. Wear 247:161–171

Sahin Y (2003) Preparation and some properties of SiC particle reinforced aluminium alloy composites. Mater Des 24:671–679

Ciftci I, Turker M, Seker U (2004) CBN cutting tool wear during machining of particulate reinforced MMCs. Wear 257:1041–1046

E. Kılıçkap, O. Çakır, M. Aksoy, A. İnan, Study of tool wear and surface roughness in machining of homogenised SiC-p reinforced aluminium metal matrix composite, Journal of Materials Processing Technology 164–165 (2005) 862–867

Mannaa A, Bhattacharayya B (2003) A study on machinability of Al/SiC-MMC. J Mater Process Technol 140:711–716

Heath PJ (2001) Developments in applications of PCD tooling. J Mater Process Technol 116:31–38

Paulo Davim J (2002) Diamond tool performance in machining metal–matrix composites. J Mater Process Technol 128:100–105

Andrewes CJE, Feng H-Y, Lau WM (2000) Machining of an aluminum/SiC composite using diamond inserts. J Mater Process Technol 102:25–29

Muthukrishnan N, Murugan M, Prahlada Rao K (2008) Machinability issues in turning of Al-SiC (10p) metal matrix composites. Int J Adv Manuf Technol 39:211–218

Palanikumar K, Muthukrishnan N, Hariprasad KS (2008) Surface roughness parameters optimization in machining a356/ SiC/20p metal matrix composites by PCD tool using response surface methodology and desirability function. Mach Sci Technol 12:529–545

Senthilkumar RC, Ganesan G, Karthikeyan R (2009) Study of electrochemical machining characteristics of Al/SiCp composites. Int J Adv Manuf Technol 43:256–263

Kok M (2010) Tool life modeling for evaluating the effects of cutting speed and reinforcements on the machining of particle reinforced metal matrix composites. Int J Miner Metall Mater 17(3):353–362

Ho KH, Newman ST, Rahimifard S, Allen RD (2004) State of the art in wire electrical discharge machining (WEDM). Int J Mach Tools Manuf 44:1247–1259

Yan BH, Tsai HC, Huang FY, Lee LC (2005) Examination of wire electrical discharge machining of Al2O3p /6061Al composites. Int J Mach Tools Manuf 45:251–259

Patil NG, Brahmankar PK (2006) Some investigations into wire electro-discharge machining performance of Al/SiCp composites. Int J Mach Mach Mater 1(4):412–431

Manna A, Bhattacharyya B (2006) Taguchi and Gauss elimination method: A dual response approach for parametric optimization of CNC wire cut EDM of PR AlSiC MMC. Int J Adv Manuf Technol 28:67–75

Seo YW, Kim D, Ramulu M (2006) Electrical discharge machining of functionally graded 15–35 vol % SiCp/Al composites. J Mater Manuf Proc 21:479–487

Sushant D, Rajesh P, Nishant S, Akhil S, Hemath Kumar G (2007) Mathematical modeling of electric discharge machining of cast Al-4Cu-6Si alloy-10 wt. % SiCp composites. J Mater Process Technol 194:24–29

Karthikeyan R, Lakshmi Narayanan PR, Naagarazan RS (1999) Mathematical modeling for electric discharge machining of aluminium–silicon carbide particulate composites. J Mater Process Technol 87:59–63

Warrier Ashish M, George PM, Raghunath BK, Manocha LM (2004) EDM machining of carbon–carbon composite–A Taguchi approach. J Mater Process Technol 145:66–71

Habib SS (2009) Study of the parameters in electrical discharge machining throughresponse surface methodology approach. Appl Math Model 33:4397–4407

Garg RK, Singh KK, Anish S, Sharma VS, Kuldeep O, Sharanjit S (2010) Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int J Adv Manuf Technol 50:611–624

Kalyanmoy D, Samir A, Amrit P, Meyarivan T (2002) A Fast Elitist Non-Dominated Sorting Genetic Algorithm for Multi-Objective Optimization: NSGA-II. IEEE Trans Evol Comput 6:2

Box GEP, Wilson KB (1951) On the Experimental Attainment of Optimum Conditions (with discussion). J R Stat Soc Ser B 13(1):1–45

Kilickap E, Huseyinoglu M, Yardimeden A (2011) Optimization of drilling parameters on surface roughness in drilling of AISI 1045 using response surface methodology and genetic algorithm. Int J Adv Manuf Technol 52:79–88

Palanikumar K (2007) Modeling and analysis for surface roughness in machining glass fibre reinforced plastics using response surface methodology. Mater Des 28:2611–2618

Palanikumar K, Latha B, Senthilkumar VS, Karthikeyan R (2009) Multiple performance optimization in machining of GFRP composites by a PCD tools using non dominated sorting genetic algorithm (NSGA-II). Met Mater Int 15(2):249–258

Kansal HK, Sehijpal S, Kumar P (2005) Parametric optimization of powder mixed electrical discharge machining by response surface methodology. Int J Mater Proc Technol 169:427–436

Yusuf Sahin A, Motorcu R (2005) Surface roughness model for machining mild steel. Mater Des 26(4):321–326

Ghafari S, Aziz HA, Isa MH, Zinatizadeh AA (2009) Application of response surface methodology (RSM) to optimize coagulation–flocculation treatment of leachate using poly-aluminum chloride (PAC) and alum. J Hazard Mater 163:650–656

Stat-Ease Inc (2001) Design-Expert Software, Educational Version 6.0.9 for Windows, John Wiley & Sons, Inc

Kanagarajan D, Karthikeyan R, Palanikumar K, Paulo Davim J (2008) Optimization of electrical discharge machining characteristics of WC/Co composites using non-dominated sorting genetic algorithm (NSGA-II). Int J Adv Manuf Technol 36:1124–1132

Saravanan R, Ramabalan S, Godwin Raja Ebenezer N, Natarajan R (2009) Evolutionary bi-criteria optimum design of robots based on task specifications. Int J Adv Manuf Technol 41:386–406

Mandal D, Pal SK, Partha S (2007) Modelling of electrical discharge machining process using back propagation neural network and multi-objective optimization using non-dominated sorting genetic algorithm-II. J Mate Proc Technol 186:154–162

Deb K (2001) Multi-objective optimization using evolutionary algorithms. Wiley, Chichester

Bhushan RK, Kumar S, Das S (2013) Fabrication and characterization of 7075 Al alloy reinforced with SiC particulates. Int J Adv Manuf Technol 65(5–8):611–624

Palanikumar K, Karthikeyan R (2006) Optimal machining conditions for turning of particulate metal matrix composites using Taguchi and response surface methodologies. Mach Sci Technol: Intern J 10(4):417–433

Montgomery DC, Peck EA, Vining GG (2003) Introduction to linear regression analysis, 3rd edn. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rao, T.B., Krishna, A.G. Selection of optimal process parameters in WEDM while machining Al7075/SiCp metal matrix composites. Int J Adv Manuf Technol 73, 299–314 (2014). https://doi.org/10.1007/s00170-014-5780-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5780-0