Abstract

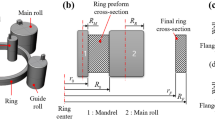

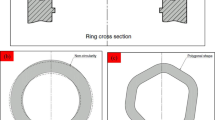

The accurate geometry and effective control during the ring rolling process are the prerequisites for the ring products’ precise forming. In this paper, the interaction modes and rules between ring and rolls in vertical hot ring rolling (VHRR) process are analyzed, and the change laws of the ring’s geometry are studied. Based on the ABAQUS/Explicit software and its subroutine VUAMP, the finite element (FE) model of the VHRR process with measurement and control is established. Then, the ring rolling process of a groove-section profile ring is simulated. During the simulation, the ring’s outer diameter, roundness error, and the stability of the rolling process are detected in time, and the close-loop control of feed plan of the drive roll and measuring roll are also employed. The results obtained show the following: (1) Four feed stages are divided by means of a step-down feed movement, that is, bite stage, main rolling stage, precise forming stage, and sizing stage. (2) At bite and main rolling stages of the VHRR process, the ring’s center swings in a spiral line, and the rolling process is unstable, the ring’s roundness becomes worse, while the process is entering the precise forming stage, by means of the guide roll, the rolling process becomes steady and the ring’s roundness tends to be better. (3) The measuring roll contacts with the ring at the main rolling stage, afterwards, it is pushed back at the precise forming stage by ring’s growth. When the measuring roll meets the desired displacement value, a stop feeding command will be fed back, and the ring rolling process enters the sizing stage. At the sizing stage, the ring’s outer diameter still increases a little. (4) A series of VHRR experiments are conducted, and FE results are in good agreement with experimental results. The absolute errors of the ring’s outer diameter and the roundness are within 1 mm. The research results of this paper have practical significance to guide the VHRR production.

Similar content being viewed by others

References

Hua L, Huang XG, Zhu CD (2001) Theory and technology of ring rolling. China Mechanical Industry Press, Beijing

Hirt G, Kopp R (2007) Implementing a high accuracy multi-mesh method for incremental bulk metal forming. CIRP Ann Manuf Technol 56(1):313–316

Zhou G, Hua L, Qian DS (2011) 3D coupled thermo-mechanical FE analysis of roll size effects on the radial-axial ring rolling process. Comput Mater Sci 50:911–924

Kebriaeia R, Frischkorna J, Reesea S (2013) Numerical modelling of powder metallurgical coatings on ring-shaped parts integrated with ring rolling. J Mater Process Technol 213(11):2015–2032

Xu WJ, Yang XB, Gong XT, Zhou J (2012) A new mathematical model for predicting the diameter expansion of flat ring in radial–axial ring rolling. Int J Adv Manuf Technol 60(9–12):913–921

Anjami N, Basti A (2010) Investigation of rolls size effects on hot ring rolling process by coupled thermo-mechanical 3D-FEA. J Mater Process Technol 210(10):1364–1377

Kim KH, Suk HG, Huh MY (2007) Development of the profile ring rolling process for large slewing rings of alloy steels. J Mater Process Technol 187–188:730–733

Jenkouk V, Hirt G, Franzke M (2012) Finite element analysis of the ring rolling process with integrated closed-loop control. CIRP Ann Manuf Technol 61(1):267–270

Wang XK, Hua L (2011) On-line measurement method for various guide modes of vertical ring rolling mill. Measurement 44(4):685–691

Wang XK, Hua L (2013) Modeling of on-line measurement for rolling the rings with blank size errors in vertical hot ring rolling process. Int J Adv Manuf Technol 68(1–4):257–262

Yin F, Hua L, Mao HJ, Han XH (2013) Constitutive modeling for flow behavior of GCr15 steel under hot compression experiments. Mater Des 43(1):393–401

Wang XK, Hua L (2011) Analysis of guide modes in vertical hot ring rolling and their effects on the ring’s dimensional precision using FE method. J Mech Sci Technol 25(3):279–285

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Hua, L., Han, X. et al. Numerical simulation and experimental study on geometry variations and process control method of vertical hot ring rolling. Int J Adv Manuf Technol 73, 389–398 (2014). https://doi.org/10.1007/s00170-014-5770-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5770-2