Abstract

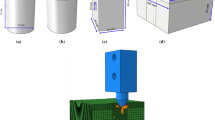

In the high-speed milling process of large end milling cutter, the stress of cutter caused by centrifugal force accounts for a large proportion of the total stress of the cutter and has a great influence on the milling process. In this paper, an end milling cutter with a diameter of 2,800 mm used on large and high-speed aluminum blank milling machine tools is taken as a research object, and the equations of internal stress caused by centrifugal force have been derived by using analytic method. On this basis, the factors affecting the internal stress were analyzed. Furthermore, the analytic results and the finite element analysis results were compared in order to confirm their correctness. Finally, according to the results of stress analysis, structure topology optimization design for large end milling cutter was carried out in order to reduce the weight and centrifugal force of the cutter.

Similar content being viewed by others

References

Ai X, Liu Z, Huang C, Deng J, Zhao J (2002) High speed cutting technology [J]. Aeronaut Manful Technol 3:20–23

Liu G, Tan, G, Li, G, Rong, Y K (2013) Multidisciplinary design optimization of a milling cutter for high-speed milling of stainless steel [J]. International Journal of Advanced Manufacturing Technology, v 68, n 9–12:p 2431–2438

Timoshenko, S. P. (2004) Theory of Elasticity [M]. Beijing: Tsinghua University:190–192

Wang X (1997) Stress analytical solution of laddering rotating wheel with variable thickness [J]. Mech Eng 19(1):20–23

Renkul A M (2011) The rotation stress of inhomogeneous viscoelasticity composite cylinder with variable thickness [J]. Applied Mathematics and Mechanics 12(4):483-492

Zenkour A M. (2006) Rotating variable-thickness orthotropic cylinder containing a solid core of uniform-thickness [J], Arch Apl Mech 76(1/2):89–102

Zenkour A M (2006) Stresses in cross-ply laminated circular cylinders of axially variable thickness [J], ActaMech 187(1):85–102

Tutuncu N (1995) Effect of anisotropy on stresses in rotating discs [J].International Journal of Mechanical Science 37(8): 873–881

Qingrong Li (1982) Internal stress analysis of a disc of uniform thickness when it is rotating at a uniform angular velocity [J].Computer Engineering: 2

Z Liu (2012) MATLAB scientific computing [M].Beijing: Electronic Industry Press:121–122

Y Qin, Y Xia, T Mao (2004) Centrifugal stress analysis of flywheel made of hybrid composite materials [J]. Acta Materiae Compositae Sinica 8, 4(21):157–161

H Ge, S Huang (2006) The theoretical calculation of elastic limit speed of high speed end milling cutter blade and its influencing factors. Modern Manufacturing Engineering,(2):78-80

Chen J-S, Huang Y-K, Cheng C.–C (2004) Mechanical model and contouring analysis of high-speed ball-screw drive systems with compliance effect. International Journal of Advanced Manufacturing Technology v 24, n 3–4, p 241–250

C Zhang (2010) ANSYS12.0 structure analysis of the engineering application examples [M]. Beijing:China Machine:509–538

Zuo K-T, Chen L-P, Zhang Y-Q, Yang, J (2007) Study of key algorithms in topology optimization [J]. International Journal of Advanced Manufacturing Technology v 32, n 7–8:p 787–796

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, Z., Wang, J. & Chen, D. Centrifugal stress analysis and structure optimization of large and high-speed end milling cutter. Int J Adv Manuf Technol 73, 101–111 (2014). https://doi.org/10.1007/s00170-014-5747-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5747-1