Abstract

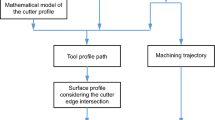

Managing macro- and micro-geometry of surfaces during manufacturing processes is a key factor for their following uses. Indeed, micro-geometry and surface topography are directly linked to the performances of functions (contact, friction, lubrication, etc.) by texture parameters to ensure the desired local geometry. Common models for simulation of surface topography are based on ideal geometry of the machining tool and cannot represent surface defects. The actual prediction and simulation of defects are one step forward in a competitive context. In this paper, the realistic model proposed aims to simulate and predict as finely as possible local defects of machined surfaces taking into account the actual edge geometry of the cutting tool. The combined use of the machining kinematics and of the measured geometry of the cutting edges leads to the representation of the geometrical envelope of the surface using a Zbuffer technique. Simulation assessment is carried out by the analysis of 3D surface topography parameters such as surface complexity and relative area and by a comparison of simulation results to an experimental case of study.

Similar content being viewed by others

References

2009 ASME B46.1: Surface texture (surface roughness, waviness, and lay). Revision of ASME B46: 1-2002

2012 ISO 25178-2: Geometrical product specifications (GPS)—surface texture: areal—Part 2: terms, definitions and surface texture parameters. ICS : 17.040.20

2013 SFrax: surface metrology and fractal analysis. http://www.surfract.com/

Antoniadis A, Savakis C, Bilalis N, Balouktsis A (2003) Prediction of surface topomorphy and roughness in ball-end milling. Int J Adv Manuf Technol 21(12):965–971. doi:10.1007/s00170-002-1418-8

Arizmendi M, Fernández J, de Lacalle LL, Lamikiz A, Gil A, Sánchez J, Campa F, Veiga F (2008) Model development for the prediction of surface topography generated by ball-end mills taking into account the tool parallel axis offset. experimental validation. CIRP Ann Manuf Technol 57(1):101–104. doi:10.1016/j.cirp.2008.03.045

Aurich J, Braun O, Warnecke G, Cronjäger L (2003) Development of a superabrasive grinding wheel with defined grain structure using kinematic simulation. CIRP Ann Manuf Technol 52(1):275–280. doi:10.1016/S0007-8506(07)60583-6

Berglund J, Brown C, Rosén BG, Bay N (2010) Milled die steel surface roughness correlation with steel sheet friction. CIRP Ann Manuf Technol 59(1):577–580. doi:10.1016/j.cirp.2010.03.140

Bouzakis K D, Aichouh P, Efstathiou K (2003) Determination of the chip geometry, cutting force and roughness in free form surfaces finishing milling, with ball end tools. Int J Mach Tools Manuf 43(5):499–514. doi:10.1016/S0890-6955(02)00265-1

Buj-Corral I, Vivancos-Calvet J (2012) Domínguez-Fernández A. Int J Mach Tools Manuf 53(1):151–159. doi:10.1016/j.ijmachtools.2011.10.006

Denkena B, Böß V, Nespor D, Samp A (2011) Kinematic and stochastic surface topography of machined TiAl6V4-parts by means of ball nose end milling. Procedia Eng 19(0):81–87. doi:10.1016/j.proeng.2011.11.083. 1st CIRP Conference on Surface Integrity (CSI)

Gao T, Zhang W, Qiu K, Wan M (2005) A new algorithm for the numerical simulation of machined surface topography in multiaxis ball-end milling. J Manuf Sci Eng 128(1):96–103. doi:10.1115/1.2123047

Guillemot N, Lartigue C, Billardon R, Mawussi B (2010) Prediction of the endurance limit taking account of the microgeometry after finishing milling. Int J Interact Des Manuf 4(4):239–249. doi:10.1007/s12008-010-0104-6

Inasaki I (1996) Grinding process simulation based on the wheel topography measurement. CIRP Ann Manuf Technol 45(1):347–350. doi:10.1016/S0007-8506(07)63077-7

Kim B, Chu C (1999) Texture prediction of milled surfaces using texture superposition method. Comput Aided Des 31(8):485–494. doi:10.1016/S0010-4485(99)00045-7

Lavernhe S, Tournier C, Lartigue C (2008) Kinematical performance prediction in multi-axis machining for process planning optimization. Int J Adv Manuf Technol 37(5-6):534–544. doi:10.1007/s00170-007-1001-4

Lavernhe S, Quinsat Y, Lartigue C (2010) Model for the prediction of 3D surface topography in 5-axis milling. Int J Adv Manuf Technol 51(9-12):915–924. doi:10.1007/s00170-010-2686-3

Liu N, Loftus M, Whitten A (2005) Surface finish visualisation in high speed, ball nose milling applications. Int J Mach Tools Manuf 45(10):1152–1161. doi:10.1016/j.ijmachtools.2004.12.007

Novovic D, Dewes R, Aspinwall D, Voice W, Bowen P (2004) The effect of machined topography and integrity on fatigue life. Int J Mach Tools Manuf 44 (2 - 3):125–134. doi:10.1016/j.ijmachtools.2003.10.018

Quinsat Y, Sabourin L, Lartigue C (2008) Surface topography in ball end milling process: Description of a 3D surface roughness parameter. J Mater Process Technol 195(1 - 3):135–143. doi:10.1016/j.jmatprotec.2007.04.129

Quinsat Y, Lavernhe S, Lartigue C (2011) Characterization of 3D surface topography in 5-axis milling. Wear 271(3 - 4):590–595. doi:10.1016/j.wear.2010.05.014. the 12th International Conference on Metrology and Properties of Engineering Surfaces

Souto-Lebel A, Guillemot N, Lartigue C, Billardon R (2011) Characterization and influence of defect size distribution induced by ball-end finishing milling on fatigue life. Procedia Eng 19:343–348. doi:10.1016/j.proeng.2011.11.123. 1st CIRP Conference on Surface Integrity (CSI)

Ungar P S, Brown C A, Bergstrom T S, Walker A (2003) Quantification of dental microwear by tandem scanning confocal microscopy and scale-sensitive fractal analyses. Scan 25(4):185–193. doi:10.1002/sca.4950250405

Zhang W H, Tan G, Wan M, Gao T, Bassir D (2008) A new algorithm for the numerical simulation of machined surface topography in multiaxis ball-end milling. J Manuf Sci Eng 003:1–11. doi:10.1115/1.2815337

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lavernhe, S., Quinsat, Y., Lartigue, C. et al. Realistic simulation of surface defects in five-axis milling using the measured geometry of the tool. Int J Adv Manuf Technol 74, 393–401 (2014). https://doi.org/10.1007/s00170-014-5689-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5689-7