Abstract

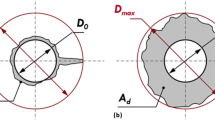

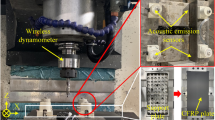

Drilling operations in composite materials introduce damage along the periphery of the hole that depends on the process parameters. Damage assessment requires image processing using either different algorithms or threshold levels for segmentation in order to be able to measure and calculate the delamination factors. The aim of this work is to carry out a systematic analysis on the image processing methodologies and algorithms to clarify and quantify their influence on the levels of delamination factors in carbon fibre-reinforced polymers (CFRP). Several tests were carried out using different types and shapes of carbide drills. The results show that both the algorithms and threshold levels for segmentation have a strong influence on the final results. Contrary to the usual procedure in the literature, the threshold level cannot be a predefined standard constant because its optimum value depends on the image histogram. The delamination factor and the adjusted delamination factor were found to be influenced by the threshold level in such a way that its increase causes an exponential decay in both factors. This clearly evidences the need to standardize the image processing methodologies so that different drilling results can be comparable.

Similar content being viewed by others

References

Persson E, Eriksson I, Zackrisson L (1997) Effects of hole machining defects on strength and fatigue life of composite laminates. Compos A: Appl Sci Manuf 28:141–151

Davim JP, Reis P (2003) Drilling carbon fiber reinforced plastics manufactured by autoclave—experimental and statistical study. Mater Des 24:315–324

Hamdoun Z, Guillaumat L, Lataillade J (2006) Influence of the drilling quality on the fatigue compression behaviour of carbon epoxy laminates. Int J Fatigue 28:1–8

Campos Rubio J, Abra˜o AM, Faria P, Correia AE, Davim JP (2008) Effects of high speed in the drilling of glass fibre reinforced plastic: evaluation of the delamination factor. Int J Mach Tools Manuf 48:715–720

Rawat S, Attia H (2009) Wear mechanisms and tool life management of WC–Co drills during dry high speed drilling of woven carbon fibre composites. Wear 267:1022–1030

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: an innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tools Manuf 49:1185–1196

Avdelidis N, Almond D, Dobbinson A, Hawtin B, Ibarra-Castanedo C, Maldague X (2004) Aircraft composites assessment by means of transient thermal NDT. Prog Aerosp Sci 40:143–162

Tsao CC, Hocheng H (2005) Computerized tomography and C-scan for measuring delamination in the drilling of composite materials using various drills. Int J Mach Tools Manuf 45:1282–1287

Tsao CC, Hocheng H (2007) Effect of tool wear on delamination in drilling composite materials. Int J Mech Sci 49:983–988

Khashaba UA (2004) Delamination in drilling GFR-thermoset composites. Compos Struct 63:313–327

Seif MA, Khashaba UA, Rojas-Oviedo R (2007) Measuring delamination in carbon/epoxy composites using a shadow moiré laser based imaging technique. Compos Struct 79:113–118

W–C C (1997) Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int J Mach Tools Manuf 37:1097–1108

Durão LMP, de Moura M, Torres Marques A (2008) Numerical prediction of delamination onset in carbon/epoxy composites drilling. Eng Fract Mech 75:2767–2778

Torres Marques A, Durão LMP, Magalhães AG, Silva JF, Tavares JMRS (2009) Delamination analysis of carbon fibre reinforced laminates: evaluation of a special step drill. Compos Sci Technol 69:2376–2382

Durão LMP, Tavares JMRS, de Albuquerque VHC, Golçalves DJS (2013) Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos Struct 96:576–583

Arul S, Vijayaraghavan L, Malhotra S, Krishnamurthy R (2006) The effect of vibratory drilling on hole quality in polymeric composites. Int J Mach Tools Manuf 46:252–259

Ho-Cheng H, Dharan CKH (1990) Delamination during drilling in composite laminates. J Eng Ind 112:236

Gaitonde VN, Karnik SR, Rubio JC, Correia AE, Abrão AM, Davim JP (2008) Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J Mater Process Technol 203:431–438

Capello E (2004) Workpiece damping and its effect on delamination damage in drilling thin composite laminates. J Mater Process Technol 148:186–195

Curnick P (2011) An investigation into the drilling of fibre-reinforced polymer composites using the optical microscopy inspection method. Insight Non-Destruct Test Cond Monit 53:248–252

Tsao CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tools Manuf 44:1085–1090

Hocheng H, Tsao CC (2005) The path towards delamination-free drilling of composite materials. J Mater Process Technol 167:251–264

Davim JP, Rubio JC, Abrão AM (2007) A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos Sci Technol 67:1939–1945

Grilo T, Paulo R, Silva C, Davim J (2013) Experimental delamination analyses of CFRPs using different drill geometries. Compos Part B 45:1344–1350

Sezgin M, Sankur B (2004) Survey over image thresholding techniques and quantitative performance evaluation. J Electron Imaging 13:146–165

Kittler J, Illingworth J (1986) Minimum error thresholding. Pattern Recogn 19:41–47

Kapur J, Sahoo P, Wong A (1985) A new method for gray-level picture thresholding using the entropy of the histogram. Comput Vision Graph Image Process 29:273–285

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, D., Pamies Teixeira, J. & Machado, C.M. Methodology analysis for evaluation of drilling-induced damage in composites. Int J Adv Manuf Technol 71, 1919–1928 (2014). https://doi.org/10.1007/s00170-014-5616-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5616-y