Abstract

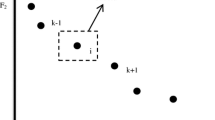

Optimization for the surface grinding process is a problem with high complexity and nonlinearity. Hence, evolutionary algorithms are needed to apply to get the optimum solution of the problem instead of the traditional optimization algorithms. In this work, a hybrid particle swarm optimization (HPSO) algorithm which combines the dynamic neighborhood particle swarm optimization (DN-PSO) algorithm with the strategy of mutation considering constraints is presented to handle multi-objective optimization for surface grinding process. Such four process parameters as wheel speed, workpiece speed, depth of dressing, and lead of dressing are considered as the variables for optimization, and the following three objectives such as production cost, production rate, and surface roughness are used in a multi-objective function model with a weighted approach. Meanwhile, the constraints of thermal damage, wheel wear, and machine tool stiffness are considered. Computational experiments are conducted on cases of both rough grinding and finish grinding, and comparison results with the previously published results obtained by using other optimization techniques shows the efficiency of the proposed algorithm.

Similar content being viewed by others

References

Malkin S (1985) Practical approaches to grinding optimization. In: Shaw MC (ed) Grinding symposium, ASME winter annual meeting. Miami Beach, FL, pp. 289–299

Amitay G, Malkin S, Koren Y (1981) Adaptive control optimization of grinding. J Eng Ind(Trans ASME) 103(1):103–108

Wen XM, Tay AAO, Nee AYC (1992) Micro-computer-based optimization of the surface grinding process. J Mater Process Technol 29(1):75–90

Saravanan R, Asokan P, Sachidanandam M (2002) A multi-objective genetic algorithm (GA) approach for optimization of surface grinding operations. Int J Mach Tools Manuf 42(12):1327–1334

Baskar N, Saravanan R, Asokan P, Prabhaharan G (2004) Ants colony algorithm approach for multi-objective optimisation of surface grinding operations. Int J Adv Manuf Technol 23(5–6):311–317

Krishna AG, Rao KM (2006) Multi-objective optimisation of surface grinding operations using scatter search approach. Int J Adv Manuf Technol 29(5):475–480

Gopala Krishna A (2007) Retracted: optimization of surface grinding operations using a differential evolution approach. J Mater Process Technol 183(2):202–209

Pawar PJ, Rao RV, Davim JP (2010) Multiobjective optimization of grinding process parameters using particle swarm optimization algorithm. Mater Manuf Process 25(6):424–431

Lee KM, Hsu MR, Chou JH, Guo CY (2011) Improved differential evolution approach for optimization of surface grinding process. Expert Syst Appl 38(5):5680–5686

Kennedy J, Eberhart R (1995) Particle swarm optimization. In: Proceedings of the IEEE international conference on neural networks, IEEE, vol 4, pp 1942–1948

Kalayci CB, Gupta SM (2013) A particle swarm optimization algorithm with neighborhood-based mutation for sequence-dependent disassembly line balancing problem. Int J Adv Manuf Technol 69(1–4):197–209

Jia Q, Seo Y (2013) An improved particle swarm optimization for the resource-constrained project scheduling problem. Int J Adv Manuf Technol 67(9–12):2627–2638

Li X, Gao L, Wen X (2012) Application of an efficient modified particle swarm optimization algorithm for process planning. Int J Adv Manuf Technol 67(5–8):1355–1369

Yildiz AR, Solanki KN (2012) Multi-objective optimization of vehicle crashworthiness using a new particle swarm based approach. Int J Adv Manuf Technol 59(1–4):367–376

Yang WA, Guo Y, Liao WH (2011) Optimization of multi-pass face milling using a fuzzy particle swarm optimization algorithm. Int J Adv Manuf Technol 54(1–4):45–57

Costa A, Celano G, Fichera S (2011) Optimization of multi-pass turning economies through a hybrid particle swarm optimization technique. Int J Adv Manuf Technol 53(5–8):421–433

Srinivas J, Giri R, Yang SH (2009) Optimization of multi-pass turning using particle swarm intelligence. Int J Adv Manuf Technol 40(1–2):56–66

Lee TS, Ting TO, Lin YJ, Htay T (2007) A particle swarm approach for grinding process optimization analysis. Int J Adv Manuf Technol 33(11–12):1128–1135

Lin X, Li H (2008) Enhanced pareto particle swarm approach for multi-objective optimization of surface grinding process. In: Second international symposium on intelligent information technology application, IITA ’08. IEEE, vol 2, pp 618–623

Hu X, Eberhart R (2002) Multiobjective optimization using dynamic neighborhood particle swarm optimization. In: Proceedings of the 2002 congress on evolutionary computation, 2002, CEC ’02. IEEE, vol 2, pp 1677–1681

Karpat Y, Özel T (2007) Multi-objective optimization for turning processes using neural network modeling and dynamic-neighborhood particle swarm optimization. Int J Adv Manuf Technol 35(3–4):234–247

Koziel S, Michalewicz Z (1999) Evolutionary algorithms, homomorphous mappings, and constrained parameter optimization. Evol Comput 7(1):19–44

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, G., Liu, M., Li, J. et al. Multi-objective optimization for surface grinding process using a hybrid particle swarm optimization algorithm. Int J Adv Manuf Technol 71, 1861–1872 (2014). https://doi.org/10.1007/s00170-013-5571-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5571-z