Abstract

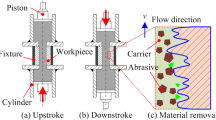

The present study examines a simple, zero-order semi-mechanistic approach towards the analysis of the two-way flow abrasive flow machining process, stemming from a need to reduce the number of time-consuming and labor-intensive experimental trials. The description consists of a set of coupled models, which are the following: an inelastic non-Newtonian model to capture the flow behavior of the abrasive media; a wall slip model, as a function of wall shear-rate, to calculate the relative motion between the media and the confining wall; and a previously derived process model describing surface roughness and stock removal evolution. Predicted results were benchmarked against experimental ones obtained from studies on straight tubes with ellipsoidal cross-sections. We end this report with an application example illustrating a method to produce uniform finishing of a tube hole with complex cross-section geometry.

Similar content being viewed by others

References

Rhoades L (1991) Abrasive flow machining: a case study. J Mater Process Technol 28:107–116

Jain VK, Kumar R, Dixit PM, Sidpara A (2009) Investigations into abrasive flow finishing of complex workpieces using FEM. Wear 267:71–80

Jain RK, Jain VK, Dixit PM (1999) Modeling of material removal and surface roughness on abrasive flow machining process. Int J Mach Tool Manuf 39:1903–9123

Buscall R (2010) Wall slip in dispersion rheometry. J Rheol 54:1177

Gorana VK, Jain VK, Lal GK (2006) Prediction of surface roughness during abrasive flow machining. Int J Adv Manuf Technol 31:258–267

Das M, Jain VK, Ghosdastidar PS (2008) Analysis of magnetorheological abrasive flow finishing (MRAFF) process. Int J Adv Manuf Technol 38:613–621

Jayswal SC, Jain VK, Dixit PM (2005) Modeling and simulation of magnetic abrasive finishing process. Int J Adv Manuf Technol 26:477–490

Wan S, Fong WS, Tay ZH “Process modelling and simulation of vibratory finishing of fixtured components”, Proc. of the 10th EUSPEN (European Society for Precision Engineering and Nanotechnology) Conf vol. 2, pp. 269–273. Oral Presentation

Queener CA, Smith TC, Mitchell WI (1965) Transient wear of machine parts. Wear 8:391–400

Sarkar AD (1976) Wear of metals. Pergamon, Oxford

Davies PJ, Fletcher AJ (1996) The assessment of the rheological characteristics of various polyborosiloxane/grit mixtures as utilized in the abrasive flow machining process. Proc Inst Mech Eng C J Mech Eng Sci 209:409–418

Jain VK, Ranganatha C, Muralidhar K (2001) Evaluation of the rheological properties of medium for AFM process. Mach Sci Technol 5(20):151–170

Wang AC, Weng SF (2007) Developing the abrasive gels in AFM process. J Mater Process Technol 192-193:496–490

Wang AC, Liu CH, Liang KZ, Pai SH (2007) Study of the rheological properties and the finishing behavior of abrasive gels. J Mech Sci Technol 21:1593–1598

Meeker SP, Bonnecaze RT, Cloitre M (2004) Slip and flow in pastes of soft particles: direct observation and rheology. J Rheol 48(6):1295–1320

Wan S Technology Disclosure, IHPC-TD-FD-2011-012 (January 2012). Instrument to gauge media consistency and polishing capability. Institute of High Performance Computing, Agency for Science, Technology and Research (A*STAR), Singapore

Macosko CW (1994) Rheology: principles, measurements and applications. Wiley-VCH, New York

Jain RK, Jain VK, Kalra PK (1999) Modelling of abrasive flow machining process: a neural network approach. Wear 231:242–248

Perti KL, Billo RE, Bidanda B (1998) A neural network process model for abrasive flow machining operations. J Manuf Syst 14(1):52–64

Sakar MR, Mondal S, Ramkumar J, Jain VK (2009) Experimental investigations and modeling of drill bit-guided abrasive flow finishing (DBG – AFF) process. Int J Adv Manuf Technol 42:678–688

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wan, S., Ang, Y.J., Sato, T. et al. Process modeling and CFD simulation of two-way abrasive flow machining. Int J Adv Manuf Technol 71, 1077–1086 (2014). https://doi.org/10.1007/s00170-013-5550-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5550-4