Abstract

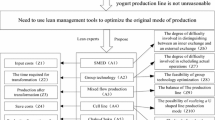

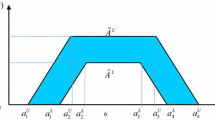

Group decision making with multiple criteria is the most popular method for ranking a set of alternatives. In this regard, all alternatives are compared based on a common criteria set. Meanwhile, decision makers sometimes encounter special situations, for example, having to select from among a set of alternatives without a set of criteria or with a set of criteria that are grouped/related to various alternatives. Thus, it may be impossible to select from among a set of alternatives using typical methods. Hence, in this study, a new, modified VIKOR method is proposed to address the lean tool selection problems in manufacturing systems. In this study, a model was developed to help practitioners improve their ability to solve problems when the possible solutions have their own individual criteria. In fact the modified VIKOR method can be applied to rank alternatives in threefold: alternatives with common criteria, without common criteria, with integrated common, and uncommon criteria. This paper offers numerical examples of the model, using a case study to illustrate an application of the proposed model and properly assess the validity of this new method. The results demonstrate the usefulness and effectiveness of the modified new method. The model covers the lack existing in the current literature to assess effectiveness of applying lean tools.

Similar content being viewed by others

References

Vinodh S, Vimal KEK (2012) “Thirty criteria based leanness assessment using fuzzy logic approach”. Int J Adv Manuf Technol 1185-1195. doi: 10.1007/s00170-011-3658

Yang Y-PO, Shieh H-M, Leu J-D, Tzeng G-H (2009) A VIKOR-based multiple criteria decision method for improving information security risk. Int J Inf Technol Decis Mak 8(2):267–287

Huang J-J, Tzeng GH, Liu HH (2009) “A revised VIKOR model for multiple criteria decision making—the perspective of regret theory”, Y. Shi et al. (eds.): MCDM 2009, CCIS 35, 761–768.

Chang CL (2010) A modified VIKOR method for multiple criteria analysis. Environ Monit Assess 168:339–344. doi:10.1007/s10661-009-1117-0

Shemshadi A, Shirazi H, Toreihi M (2011) A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Syst Appl 38:12160–12167

Opricovic S, Tzeng GH (2004) Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur J Oper Res 156:445–455

Bayou ME, Korvin A (2008) Measuring the leanness of manufacturing systems—a case study of Ford Motor Company and General Motors. J Eng Technol Manag 25:287–304

Ohno T (1998) Toyota production system: beyond large-scale production. Productivity Press, Portland

Womack JP, Jones DT (2003) LEAN THINKING: banish waste and create wealth in your corporation. Simon and Schuster, London

Liker JK (2004) The Toyota way: 14 management principles from the world’s greatest manufacturer. McGraw-Hill, New York

Smith R, Hawkins B (2004) “Lean maintenance,” Elsevier Butterworth–Heinemann, Oxford, UK 99, 42-43.

Dahlgaard JJ, Dahlgaard-Park S (2006) Lean production, six sigma quality, TQM and company culture. TQM Mag 18(3):263–281

Grewal C (2008) An initiative to implement lean manufacturing using value stream mapping in a small company. Int J Manuf Technol Manag 15(3):404–417

Marchwinski C, Shoo J (2010) “Lean lexicon: a graphical glossary for lean thinkers”, Lean Enterprise Institute, ISBN: 0966784367.

Steinlicht CL (2011) “Lean production and the organizational life cycle: a survey of lean tool effectiveness in young and mature organizations”, doctoral dissertation. CAPELLA UNIVERSITY, US

Van Erp M, Schomaker L (2002) “An overview and comparison of voting methods for pattern recognition”, in Proc. 8th Int. Workshop Frontiers Handwriting Recogn., 195–200.

Liu P, Wang M (2011) An extended VIKOR method for multiple attribute group decision making based on generalized interval-valued trapezoidal fuzzy numbers. Sci Res Essays 6(4):766–776

Zikmund WG (2013) Business research methods, 7th edn. South-Western, Ohio

Wan H, Chen F (2007) “Leanness score of value stream maps”, Proceedings of the 2007 Industrial Engineering Research Conference G. Bayraksan, W. Lin, Y. Son, and R. Wysk, eds.

Bowen P, Cattell K, Jay I (2011) Value management in the South African manufacturing industry: exploratory findings. Manag Decis 49(1):6–28

Li C (2011) A customised lean model for a Chinese aerospace OEM (original equipment manufacturer). Cranfield University, UK, MS thesis

Taj S (2005) “Applying lean assessment tools in Chinese hi-tech industries”, Collage of Business Administration, University of Detroit Mercy, and Detroit. Michigan, USA

Herron C, Braiden PM (2006) A methodology for developing sustainable quantifiable productivity improvement in manufacturing companies. Int J Prod Econ 104(1):143–153

Wilson L (2010) “How to implement lean manufacturing”, McGraw Hill, New York Chicago San Francisco Lisbon London Madrid Mexico City Milan New Delhi San Juan Seoul Singapore-ISBN: 978-0-07-162508-1.

Rivera L, Chen FF (2007) Measuring the impact of lean tools on the cost–time investment of a product using cost–time profiles║. Robot Comput Integr Manuf 23(6):684–689

Lam L, Suen CY (1997) Application of majority voting to pattern recognition: an analysis of its behavior and performance. IEEE Trans Syst Man Cybern Syst Hum 27(5):553

Obata T, Ishii H (2003) A method for discriminating efficient candidates with ranked. Voting data. Eur J Oper Res 151:233–237

Lee D-S, Srihari SN (1993) “Hand printed digit recognition: a comparison of algorithms”, in Proc. 3rd Int. Workshop Frontiers Hand writing Recognition, Buffalo, NY, 153–162.

Mahapatra SS, Mohanty SR (2007) Lean manufacturing in continuous process industry: an empirical study. J Sci Ind Res 66:19–27

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anvari, A., Zulkifli, N. & Arghish, O. Application of a modified VIKOR method for decision-making problems in lean tool selection. Int J Adv Manuf Technol 71, 829–841 (2014). https://doi.org/10.1007/s00170-013-5520-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5520-x