Abstract

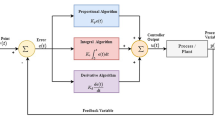

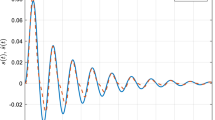

This paper discusses how to improve the position precision of a semi-closed loop servo system. A support vector regression algorithm is chosen to model and predict position error. The predicted error is then fed back to the input entry to compensate the error. Fuzzy PID control is introduced to adjust the controlling rule of the PID controller in the semi-closed loop servo system so as to improve the dynamic response characteristics of the servo system and reach a high degree of position precision. A case study is implemented. The simulation and experimental results show that combining the improved fuzzy control with predicted position error feedback ensures a high degree of position precision and a high degree of dynamic response characteristics.

Similar content being viewed by others

References

Pritschowa G, Bretschneidera J (1999) A self-tuning controller for digitally controlled electromechanical servo drives in machine tools. CIRP Ann Manuf Technol 48(1):307–312

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools—a review part I: geometric, cutting-force induced, and fixture-dependent errors. Int J Mach Tools Manuf 40(9):1235–1256

Ziegert JC, Kalle P (1994) Error compensation in machine tools: a neural network approach. J Intell Manuf 5:143–151

Ang JH, Goh CK, Teoh EJ, Tan KC (2007) Designing a recurrent neural network-based controller for gyro-mirror line-of-sight stabilization system using an artificial immune algorithm. Stud Comput Intell 66:189–209

Yang S, Yuan J, Ni J (1996) The improvement of thermal error modeling and compensation on machine tools by CMAC neural network. Int J Mach Tools Manuf 36(4):527–537

Yuan J, Ni J (1998) The real-time error compensation technique for CNC machining systems. Mechatronics 8:359–380

Xie SQ, Yu PL, Sheng B, Zhou ZD (2001) An integral sliding model tracking strategy for 3d laser beam position control. Int J Adv Manuf Technol 18:633–640

Jee S, Koren Y (2004) Adaptive fuzzy logic controller for feed drives of a CNC machine tool. Mechatronics 14:299–326

Lertpiriyasuwat V, Berg MC (2006) Adaptive real-time estimation of end-effector position and orientation using precise measurements of end-effector position. IEEE/ASME Trans Mechatronics 11(3):304–319

Yang JZ, Li ZX (2011) A novel contour error estimation for position loop-based cross-coupled control. IEEE/ASME Trans Mechatronics 16(4):643–655

Ding F, Qu MC, Lin YQ (2003) Realization of PID control method in AC position servo system. Electro-Mech Eng 19:52–54

Veldhuis SC, Elbestawi MA (1995) A strategy for the compensation of error in five-axis machining. Ann CIRP 44(1):373–377

Ferreira PM, Liu CR (1986) An analytical quadratic model for the geometric errors of a machine tool. J Manuf Syst 5(1):51–62

Hirose N, Iwasaki M, Kawafuku M, Hirai H (2009) Initial value compensation using additional input for semi-closed control systems. IEEE Trans Ind Electron 56(3):635–641

Goto S, Nakamura M (2006) Multidimensional feedforward compensator for industrial systems through pole assignment regulator and observer. IEEE Trans Ind Electron 53(3):886–894

Vapnike V (1999) The Nature of Statistical Learning Theory. Springer, N. Y

Burges JC (2002) A tutorial on support vector machines for pattern recognition. Data Min Knowl Disc 2:121–167

Chakguy P, Theodore BT, Raman S (2003) Support vector regression for determination of minimum zone. ASME J Manuf Sci E-T 125(4):736–739

Keerthi SS et al (1999) “A fast iterative nearest point algorithm for support vector machine classifier design.” Indian Institute of Science Bangatolore

Stella MC, Jan HG, Timothy WS (2005) Analysis of support vector regression for approximation of complex engineering analyses. J Mech Des 127(6):1076–1087

Lin YL, Hsieh JG, Wu HK, Jeng JH (2011) “Three-parameter sequential minimal optimization for support vector machines.” Neurocomputing In Press

Suykens JAK, Branbanter JK, Lukas L (2002) Weighted least squares support vector machines: Robustness and spare approximation. Neurocomputing 48(1):85–105

Jayadeva, Reshma K, Suresh C (2008) Regularized least squares support vector regression for the simultaneous learning of a function and its derivatives. Inform Sci 178(17):3402–3414

Kapoor SG, DeVor RE, Zhu R (1998) Development of mechanistic models for the prediction of machining performance: model building methodology. Mach Sci Technol 2(1):213–238

Chinnam RB (2002) Online reliability estimation for individual components using statistical degradation signal models. Qual Reliab Eng Int 18(1):53–73

Theodor F, Hu SJ (2002) Impact of machining parameters on machine reliability and system productivity. ASME J Manuf Sci E-T 124(2):296–304

Meng S, Yoshiharu F et al (2002) Handwritten numeral recognition using gradient and curvature of gray scale image. Pattern Recogn 35(10):2051–2059

Liu CL, Masaki N (2001) Evaluation of prototype learning algorithms for nearest-neighbor classifier in application to handwritten character recognition. Pattern Recogn 34(3):601–615

Lee JH, Yang SH (2001) Fault diagnosis and recovery for a CNC machine tool thermal error compensation system. J Manuf Syst 19(6):428–434

Donmez A (1986) A general methodology for machine tool accuracy enhancement by error compensation. Precis Eng 8(4):187–196

Anjanappa M, Anand DK, Kirk JA (1988) Error correction methodologies and control strategies for numerical control machines. Control Method Manuf Process 7:41–49

Islam S, Liu PX (2011) Robust adaptive fuzzy output feedback control system for robot manipulators. IEEE/ASME Trans Mechatronics 16(2):288–296

Chen YF, Zhu DM, Zhu GB, Wang HZ (2008) The application of an improved PID control in servo control. Servo Control 1:53–55

Zhou Y, Chen JH, Peng FY (2007) Mechatronic integrated system simulation for a high-speed and high-precision CNC feed drive. Mech Sci Technol 26(2):135–139

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, C., Xie, S.Q., Wu, J. et al. Position error compensation of semi-closed loop servo system using support vector regression and fuzzy PID control. Int J Adv Manuf Technol 71, 887–898 (2014). https://doi.org/10.1007/s00170-013-5495-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5495-7