Abstract

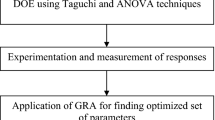

Aluminum 6061-T6 is an important alloy as it has dominant mechanical properties like weldability and hardness, and has the potential to be used at variable temperatures. AL6061-T6 is frequently used in the aerospace industry, as well as aircraft, automotive, and packaging food industries. Milling of Al6061-T6 is important especially to produce various product shapes for adapting to diverse applications. The aptitude of the CNC milling machine for batch production would be a noteworthy advantage. However, the demand for high quality brings attention to product quality, particularly the roughness of the machined surface because of its effect on product appearance, function, and reliability. Introducing correct lubrication to the machining zone could improve the tribological characteristics of Al6061-T6. For additional improvement, applying nanolubrication may produce superior product quality, as the rolling action of billions of nanoparticle units in the tool chip interface can significantly decrease the cutting forces. In this research work, the optimum MoS2 nanolubrication parameters in Al6061-T6 milling to achieve the lowest cutting force, cutting temperature and surface roughness are investigated. The parameters include nanolubricant concentration, nozzle orientation and air carrier pressure. Taguchi optimization along with standard orthogonal array L16(43) are employed. Furthermore, surface roughness and cutting force are analyzed via signal-to-noise (S/N) response analysis and the analysis of variance (Pareto ANOVA) in the hopes of achieving optimum conditions and to determine which process parameters are statistically significant. Finally, optimization improvements are investigated through confirmation tests.

Similar content being viewed by others

Reference

Lakshminarayanan A, Balasubramanian V, Elangovan K (2009) Effect of welding processes on tensile properties of AA6061 aluminium alloy joints. Int J Adv Manuf Technol 40:286–296

Shankar MR, Chandrasekar S, Compton WD, King AH (2005) Characteristics of aluminum 6061-T6 deformed to large plastic strains by machining. Mater Sci Eng A 410–411:364–368

Li Y, Liang SY (1999) Cutting force analysis in transient state milling processes. Int J Adv Manuf Technol 15:785–790

Hsu SM (2004) Nano-lubrication: concept and design. Tribol Int 37:537–545

Lee J, Cho S, Hwang Y, Cho HJ, Lee C, Choi Y, Ku BC, Lee H, Lee B, Kim D, Kim SH (2009) Application of fullerene-added nano-oil for lubrication enhancement in friction surfaces. Tribol Int 42:440–447

Tao X, Jiazheng Z, Kang X (1996) The ball-bearing effect of diamond nanoparticles as an oil additive. J Phys D Appl Phys 29:2932–2937

Lathkar GS, Bas USK (2000) Clean metal cutting process using solid lubricants. In: Proceedings of the 19th AIMTDR conference. Narosa Publishing House IIT Madras, pp 15–31

Reddy NSK, Nouari M, Yang M (2010) Development of electrostatic solid lubrication system for improvement in machining process performance. Int J Mach Tools Manuf 50:789–797

Dilbag S, Rao PV (2008) Performance improvement of hard turning with solid lubricants. Int J Adv Manuf Technol 38:529–535

Sharma VS, Dogra M, Suri NM (2009) Cooling techniques for improved productivity in turning. Int J Mach Tools Manuf 49:435–453

Sreejith PS, Ngoi BKA (2000) Dry machining: machining of the future. J Mater Process Technol 101:287–291

Klocke F, Eisenblätter G (1997) Dry cutting. CIRP Ann Manuf Technol 46:519–526

Lee P, Naam JS, Li C, Lee SW (2012) An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int J Precis Eng Manuf 13(3):331–338

He S (1982) Solid lubrication materials for high temperature: a review. Tribol Int 15:303–314

Miaosun S (2000) Solid lubrication materials. China Chemistry Press, Beijing

Nakamura T, Tanaka S, Hayakawa K, Fukai Y (2000) A study of the lubrication behavior of solid lubricants in the upsetting process. J Tribol 122:803–808

Alberts M, Kalaitzidou K, Melkote S (2009) An investigation of graphite nanoplatelets as lubricant in grinding. Int J Mach Tools Manuf 49:966–970

Deshmukh SD, Basu SK (2006) Significance of solid lubricants in metal cutting, in: 22nd AIMTDR

Sayuti M, Sarhan AAD, Hamdi M (2013) An investigation of optimum SiO2 nanolubrication parameters in end milling of aerospace Al6061-T6 alloy. Int J Adv Manuf Technol 67(1–4):833–849

Keblinski P, Phillpot SR, Choi SUS, Eastman JA (2002) Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int J Heat Mass Transf 45:855–863

Wang W, Liu K, Jiao M (2007) Thermal and non-Newtonian analysis on mixed liquid–solid lubrication. Tribol Int 40:1067–1074

Lee JH, Hwang KS, Jang SP, Lee BH, Kim JH, Choi SUS, Choi CJ (2008) Effective viscosities and thermal conductivities of aqueous nanofluids containing low volume concentrations of Al2O3 nanoparticles. Int J Heat Mass Transf 51:2651–2656

Murshed SMS, Leong KC, Yang C (2009) A combined model for the effective thermal conductivity of nanofluids. Appl Therm Eng 29:2477–2483

Masmiati N, Sarhan AAD, Hamdi M (2012) Optimizing the cutting parameters for better surface quality in 2.5D cutting utilizing titanium coated carbide ball end mill. Int J Precis Eng Manuf 13(12):2097–2102

Davis JR (1990) Metals handbook, Vol. 2 — Properties and selection: Nonferrous alloys and special-purpose material, 10th edn. ASM International, Materials Park, OH

Liew WYH (2010) Low-speed milling of stainless steel with TiAlN single-layer and TiAlN/AlCrN nano-multilayer coated carbide tools under different lubrication conditions. Wear 269:617–63

Yan J, Zhang Z, Kriyagawa T (2011) Effect of nano-particle lubrication in diamond turning of reaction-bonded SiC. Int J Autom Technol 5:307–312

Hung TC, Su YT (2006) A method for reducing tool wear in a polishing process. Int J Mach Tools Manuf 46:413–423

Wu YY, Tsui WC, Liu TC (2007) Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262:819–825

Mu-Jung Kao CRL (2009) Evaluating the role of spherical titanium oxide nanoparticles in reducing friction between two pieced of cast iron. J Alloys Compd 483:456–459

Sarhan AAD, Sayuti M, Hamdi M (2012) Reduction of power and lubricant oil consumption in milling process using a new SiO2 nanolubrication system. Int J Adv Manuf Technol 63(5–8):505–512

Yousefi YIR (2000) A study on ultra-high-speed cutting of aluminium alloy: formation of welded metal on the secondary cutting edge of the tool and its effects on the quality of finished surface. J Int Soc Precis Eng Nanotechnol 24:371–376

N Suresh Kumar Reddy, P Venkateswara Rao (2006) Experimental investigation to study the effect of solid lubricants on cutting forces and surface quality in end milling. Int J Mach Tools Manuf 46:189–198

Sayuti M, Sarhan AAD, Tanaka T, Hamdi M, Saito Y (2013) Cutting force reduction and surface quality improvement in machining of aerospace duralumin AL-2017-T4 using carbon onion nanolubrication system. Int J Adv Manuf Technol 65(9–12):1493–1500

Wakabayashi SST, Inasaki I, Terasaka K, Musha Y, Toda Y (2007) Tribological action and cutting performance of MQL media in machining of aluminium. Ann CIRP 56/1

Lin HSYC (2004) Limitations on use of ZDDP as an antiwear additive in boundary lubrication. Tribol Int 37:25–33

Prado LEMRA, Shindo DJ, Soto KF (2001) Tool wear in the friction-stir welding of aluminium alloy 6061 + 20% Al2O3: a preliminary study. Scr Mater 45:75–80

Hamdan AA, Sarhan AAD, Hamdi M (2012) An optimization method of the machining parameters in high speed machining of stainless steel using coated carbide tool for best surface finish. Int J Adv Manuf Technol 58(1):81–91

Rapoport ONL, Lapsker I, Verdyan A, Moshkovich A, Feldman Y, Tenne R (2005) Behavior of fullerene-like WS2 nanoparticles under severe contact conditions. Wear 259:703–707

Rapoport VLL, Lvovsky M, Nepomnyashchy O, Volovik Y, Tenne R (2002) Mechanism of friction of fullerenes. Ind Lubr Tribol 54:171–176

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahmati, B., Sarhan, A.A.D. & Sayuti, M. Investigating the optimum molybdenum disulfide (MoS2) nanolubrication parameters in CNC milling of AL6061-T6 alloy. Int J Adv Manuf Technol 70, 1143–1155 (2014). https://doi.org/10.1007/s00170-013-5334-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5334-x