Abstract

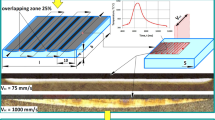

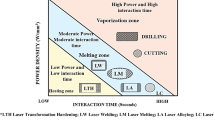

For laser surface hardening (LSH) of large-sized workpieces, a wide and uniform hardened layer of a single track is pursued. In this study, two kinds of shaped laser beams were used in LSH of 42CrMo cast steel to obtain the required hardened layer. One is a stripy spot with uniform-intensity array spots and the other a stripy spot with intensity blowup in the edge of the whole array spots. As a comparison, a Gaussian laser beam was also adopted. A three-dimensional finite element model was used to simulate the thermal history of specific points by the latter shaped beam and the Gaussian laser beam. The surface morphology, microstructure, microhardness, and uniformity of hardened layers were studied. The results showed that a wider and more uniform hardened layer could be obtained using the latter shaped beam at relative higher scanning velocities and laser power. The thermal history of a material has an important effect on the microstructure and microhardness finally formed. Due to the high peak temperature and heating rate caused by the latter shaped beam, a higher value of microhardness in the transformation hardened zone was found.

Similar content being viewed by others

References

Shin HJ, Yoo YT, Ahn DG, Im K (2007) Laser surface hardening of S45C medium carbon steel using ND:YAG laser with a continuous wave. J Mater Process Technol 187–188:467–470

Wu W, Liang NG, Gan CH, Yu G (2006) Numerical investigation on laser transformation hardening with different temporal pulse shapes. Surf Coat Technol 8:2686–2694

Dinesh Babu P, Buvanashekaran G, Balasubramanian KR (2013) Experimental investigation of laser transformation hardening of low alloy steel using response surface methodology. Int J Adv Manuf Technol 67:1883–1897

Xu H, Chen WW, Zhou K, Huang Y, Wang QJ (2010) Temperature field computation for a rotating cylindrical workpiece under laser quenching. Int J Adv Manuf Technol 47:679–686

Giorleo L, Previtali B, Semeraro Q (2011) Modelling of back tempering in laser hardening. Int J Adv Manuf Technol 54:969–977

Chen SL, Shen D (1999) Optimization and quantitative evaluation of the qualities for Nd-YAG laser transformation hardening. Int J Adv Manuf Technol 15:70–78

Zhou P, Ma YX, Wang XL, Ma HT, Xu XJ, Liu ZJ (2009) Average intensity of a partially coherent rectangular flat-topped laser array propagating in a turbulent atmosphere. Appl Optics 48:5251–5258

Li CW, Wang Y, Han B (2011) Microstructure, hardness and stress in melted zone of 42CrMo steel by wide-band laser surface melting. Opt Lasers Eng 49:530–535

Hagino H, Shimizu S, Ando H, Kikuta H (2010) Design of a computer-generated hologram for obtaining a uniform hardened profile by laser transformation hardening with a high-power diode laser. Precis Eng 34:446–452

Hwang J-H, Lee Y-S, Kim D-Y, Youn J-G (2002) Laser surface hardening of gray cast iron used for piston ring. J Mater Eng Perform 11:294–300

Pantelis D, Bouyiouri E, Kouloumbi N, Vassiliou P, Koutsomichalis A (2002) Wear and corrosion resistance of laser surface hardened structural steel. Surf Coat Technol 161:125–134

Sandven O (1981) Laser surface transformation hardening. Metals handbook, 9th edn. ASM, Metals Park, OH

Soriano C, Leunda J, Lambarri J, Garcia Navas V, Scanz C (2011) Effect of laser hardening on the microstructure, hardness and residual stresses of austempered ductile iron grades. Appl Surf Sci 257:7101–7106

Leung MKH, Man HC, Yu JK (2007) Theoretical and experimental studies on laser transformation hardening of steel by customized beam. Int J Heat Mass Transfer 50:4600–4606

Kock DJ (2004) Lasers offer unique heat treating capabilities. www.industrialheating.com

Safdar S, Li L, Sheikh MA, Liu Z (2006) An analysis of the effect of laser beam geometry on laser transformation hardening. J Manuf Sci E-T ASME 12:8659–8667

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, P., Li, S., Yu, G. et al. Laser surface hardening of 42CrMo cast steel for obtaining a wide and uniform hardened layer by shaped beams. Int J Adv Manuf Technol 70, 787–796 (2014). https://doi.org/10.1007/s00170-013-5292-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5292-3