Abstract

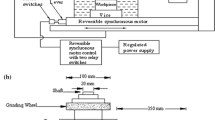

Machining of metal matrix composites (MMCs) has been a big challenge for manufacturing industries due to its superior mechanical properties. Unconventional machining methods have become an alternative to give desired shapes with intricate profiles and stringent design requirements. The present research investigates the grinding performance of copper–iron–graphite MMC using electric discharge diamond face grinding (EDDFG), which is electric discharge machining-based hybrid machining process. Experiments have been performed on a self-developed experimental setup of EDDFG with scientifically designed experiments. Effects of process input parameters on two important performances, material removal rate (MRR) and surface roughness (SR), have been analyzed. Genetic algorithm-based optimization of MRR and SR models show considerable improvements in both characteristics, as confirmed by verification experiments. Results reveal that peak current is a common significant factor for both MRR and SR.

Similar content being viewed by others

References

Garg RK, Singh KK, Sachadeva A, Sharma V, Ojha K (2010) Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int J Adv Manuf Technol 50:611–624. doi:10.1007/s00170-010-2534-5

Karl UK (2006) Metal matrix composites: custom-made materials for automotive and aerospace engineering. WILEY-VCH, New York

Jain VK (2002) Advanced machining processes. Allied Publishers, New Delhi

Pandey PC, Shan HS (1997) Modern machining processes. Tata McGraw-Hill Publishing Company Ltd, New Delhi

Ozgedik A, Can C (2006) An experimental investigation of tool wear in electric discharge machining. Int J Adv Manuf Technol 27:488–500. doi:10.1007/s00170-004-2220-6

Kansal HK, Singh S, Kumar P (2005) Parametric optimization of powder mixed electric discharge machining by response surface methodology. J Mater Process Technol 169:427–436. doi:10.1016/j.jmatprotec.2005.03.028

Lauwers B, Kruth JP, Lin W, Eeraerts W, Schacht B, Bleys P (2004) Investigation of material removal mechanisms in EDM of composite ceramic materials. J Mater Process Technol 149:347–352. doi:10.1016/j.jmatprotec.2004.02.013

Ramulu M, Paul G, Patel J (2001) EDM surface effect on the fatigue strength of a 15 vol% SiCp/Al metal matrix composite material. Compos Struct 54:79–86. doi:10.1016/s0263-8223(01)00072-1

Mohan B, Rajadurai A, Satyanarayana KG (2004) Electric discharge machining of Al-SiC metal matrix composites using rotary tube electrode. J Mater Process Technol 153–154:978–985. doi:10.1016/j.jmatprotec.2004.04.347

Ji RJ, Liu YH, Zhang YZ, Wang F, Cai BP, Li H (2012) Compound machining of silicon carbide ceramics by high speed end electrical discharge milling and mechanical grinding. Chin Sci Bull 57(4):421–434. doi:10.1007/s11434-011-4822-3

Ji RJ, Liu YH, Zhang YZ, Wang F, Cai BP, Li H, Ma J (2010) Optimizing machining parameters of silicon carbide ceramics with ED milling and mechanical grinding combined process. Int J Adv Manuf Technol 51(1–4):195–204. doi:10.1007/s00170-010-2628-0

Ji RJ, Liu YH, Zhang YZ, Wang F, Cai BP, Li H, Dong X (2012) Machining performance optimization in end ED milling and mechanical grinding compound process. Mater Manuf Process 27(2):221–228. doi:10.1080/10426914.2011.568569

Ji RJ, Liu YH, Zhang YZ, Wang F, Li H, Cheng XD (2010) Machining performance and surface integrity of SiC ceramic machined using electrical discharge milling and the mechanical grinding compound process. Proc IME B J Eng Manufact 224(10):1511–1518. doi:10.1243/09544054JEM1863

Jain VK, Choudhary SK, Gupta M (1999) Electrical discharge diamond grinding of high speed steel. Machi Sci Technol 3(1):91–105. doi:10.1080/10940349908945685

Koshy P, Jain VK, Lal GK (1996) Mechanism of material removal in electrical discharge diamond grinding. Int J Mach Tools Manuf 36:1173–1185. doi:10.1016/0890-6955(95)00103-4

Kumar S, Choudhury SK (2007) Prediction of wear and surface roughness in electrodischarge diamond grinding. J Mater Process Technol 191(1):206–209

Chandrasekhar BA, Yadava V, Singh GK (2010) Development and experimental study of electro-discharge face grinding. Mater Manuf Process 25:1–6. doi:10.1080/10426910903367436

Koshy P, Jain VK, Lal GK (1999) Grinding of cemented carbide with electrical spark assistance. J Mater Process Technol 72:61–68. doi:10.1016/S0924-0136(97)00130-1

Singh GK, Yadava V, Kumar R (2010) Diamond face grinding of WO-CO composite with spark assistance: experimental study and parameter optimization. Int J Precis Eng Manuf 11(4):509–518. doi:10.1007/s12541-010-0059-3

Shrivastava A, Dubey AK, Shrivastava PK (2012) Computer-aided hybrid ANN-GA approach for modeling and optimization of EDDG process. Int J Abra Technol 5:245–257. doi:10.1504/IJAT.2012.051034

Phadke MS (1989) Quality engineering using robust design. Prentice-Hall, Englewood Cliffs

Montgomery DC (1997) Design and analysis of experiments. Wiley, New York

Deb K (1995) Optimization for engineering design: algorithms and examples. Prentice-Hall of India Pvt Ltd, New Delhi

Lamba VK (2008) Neuro fuzzy systems. University Science Press, New Delhi

Rao PN (2004) Manufacturing technology-metal cutting and machine tools. Tata McGraw-Hill Publishing Company Limited, New Delhi

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shrivastava, P.K., Dubey, A.K. Experimental modeling and optimization of electric discharge diamond face grinding of metal matrix composite. Int J Adv Manuf Technol 69, 2471–2480 (2013). https://doi.org/10.1007/s00170-013-5190-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5190-8