Abstract

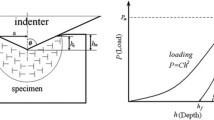

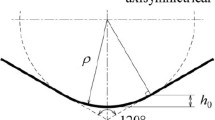

Elementary indentation processes are relatively simple compression processes and they are quite extended in many fields of the industry. Nevertheless, the concatenation of these processes is a new approach and has interest from a technological point of view. Incremental forming processes can be carried out in CNC machines with more flexibility, lower force requirements and simpler tools than in conventional forging processes. The purpose of this work is the analysis of the three-dimensional geometry resulting from the multiple indentation process. Based on the surface rugosity parameters defined in the specification standard ISO 4287, the state of the 3D-formed surface by several types of tools is studied and a predictive evaluation model has been developed in order to quantify, by means of shape parameters S a and S M , the topography of the expected surface and the amount of material displaced depending on the technological and geometrical characteristics of the process.

Similar content being viewed by others

References

Groche P, Fritsche D, Tekkaya EA, Allwood JM, Hirt G, Neugebauer R (2007) Incremental bulk metal forming. CIRP Ann Manuf Technol 56:635–656

Allwood JM, Utsunomiya H (2006) A survey of flexible forming processes in Japan. Int J Mach Tool Manuf 46:1939–1960

Nowak J, Madej G, Grosman F, Pietrzyk M (2010) Material flow analysis in the incremental forging technology. Int J Mater Form 3:931–934

Sebastián, M.A., Camacho, A.M. (2007). Geometrical study and basis for the analysis of localized-incremental forging processes by FEM. 2nd International Conference on New Forming Technology. Bremer Institut für angewandte Strahltechnik (BIAS). 295-304. ISSN/ISBN: 978-3-933762-22-1

Camacho AM, Sebastián MA (2008) Analysis of competitive localized-incremental forging processes. Innov Prod Mach Syst 457–462

Camacho AM, Vallellano C, García-Lomas J, Sebastián MA (2010) Effect of punch geometry on strain/stress state induced in workpiece by localised-incremental forging operations. Steel Res Int 81:958–961

Camacho, A.M., Marin, M.M. Bernal, C. Sebastián, M.A. (2013). Implicit and explicit techniques for Localized-Incremental Forging processes analysis by Computer Aided Engineering. The International Journal of Computer Aided Engineering and Technology, in press

Jianming W, Feihong L, Feng Y, Gang Z (2011) Shot peening simulation based on SPH method. Int J Adv Manuf Technol 56:571–578

Ambrogio G, Filice L, Gagliardi F (2011) Enhancing incremental sheet forming performance using high speed. Key Eng Mater 473:847–852

Luo Y, He K, Du R (2010) A new sheet metal forming system based on the incremental punching, part 1: modeling and simulation. Int J Adv Manuf Technol 51:481–491

Luo Y, He K, Du R (2010) A new sheet metal forming system based on incremental punching, part 2: machine building and experiment results. Int J Adv Manuf Technol 51:493–506

Camacho, A.M. Marín, M.M. Bernal, C. Sebastián, M.A. (2011) Simulation and experimental techniques for the analysis of localised-incremental forging operations. Proceedings of the European Simulation and Modelling Conference 2011, edited by EUROSIS, Ghent University

Camacho AM, Marin MM, Rubio EM, Sebastián MA (2011) Application of different simulation strategies for the analysis of multi-stroke localised-incremental forging operations. Mater Sci Forum 713:19

Micari F, Ambrogio G, Filice L (2007) Shape and dimensional accuracy in single point incremental forming: state of the art and future trends. J Mater Process Technol 191:390–395

ISO 4287 (1997) Geometrical Product Specifications (GPS). Surface texture: profile method. Terms, definitions and surface texture parameters. International Organization for Standardization (ISO), Geneva

ISO 4288 (1996) Geometrical Product Specifications (GPS). Surface texture: profile method. Rules and procedures for the evaluation of surface texture. International Organization for Standardization (ISO), Geneva

Ahn D, Kweon JH, Choi J, Lee S (2012) Quantification of surface roughness of parts processed by laminated object manufacturing. J Mater Process Technol 212(I2):339–346. doi:10.1016/j.jmatprotec.2011.08.013

Bernal C, Camacho AM, Arenas JM, Rubio EM (2012) Analytical procedure for geometrical evaluation of flat surfaces formed by multiple indentation processes. Appl Mech Mater 217–219:2351–2356

Dong WP, Mainsah E, Stout KJ (1995) Reference planes for the assessment of surface roughness in three dimensions. Int J Mach Tool Manuf 35:263–271

Stout KJ (1994) The three dimensional surface topography: measurement, interpretation and application. Penton Press, London

Dong WP, Sullivan PJ, Stout KJ (1994) Comprehensive study of parameters for characterizing 3-dimensional surface-topography. III: parameters for characterizing amplitude and some functional-properties. Wear 178:29–43

Zhongxiang H, Lei Z, Jiaxu T, Xuehong M, Xiaojun S (2009) Evaluation of three-dimensional surface roughness parameters based on digital image processing. Int J Adv Manuf Technol 40:342–348

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bernal, C., Camacho, A.M., Marín, M.M. et al. Methodology for the evaluation of 3D surface topography in multiple indentation processes. Int J Adv Manuf Technol 69, 2091–2098 (2013). https://doi.org/10.1007/s00170-013-5164-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5164-x