Abstract

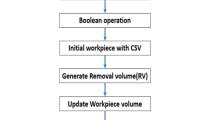

Manufacturers produce complex parts by utilizing computer-aided manufacturing (CAM) software to generate tool paths for a machine tool to follow. CAM systems traditionally rely on parametric surface representations of the parts and complex algorithms to produce the tool paths. This paper presents a new path generation framework that is based on parallel algorithms and hardware that utilizes voxel models. The use of new parallel algorithms allows rapid calculations of tool paths automatically from the voxel model. The core components of this framework are a method of generating digital voxel models from tessellated surface models, a method to obtain digital surface information by a parallel ray-casting approach, and a new approach to calculate gouge-free tool paths in parallel from surface information and generalized cutting geometry. The performance of utilizing digital models within this framework is then discussed with respect to timing and actual cutting results.

Similar content being viewed by others

References

Broomhead P, Edkins M (1986) Generating NC data at the machine tool for the manufacture of free-form surfaces. Int J Prod Res 24(1):1–14

Elber G, Cohen E (1993) Tool path generation for freeform surface models. Proceedings on the second ACM symposium on solid modeling and applications, 1993. pp 419–428

Loney GC, Ozsoy TM (1987) NC machining of free form surfaces. Comput-Aided Des 19(2):85–90

Bobrow JE (1985) NC machine tool path generation from CSG part representations. Comput-Aided Des 17(2):69–76

Huang Y, Oliver JH (1994) Non-constant parameter NC tool path generation on sculptured surfaces. Int J Adv Manuf Technol 9(5):281–290

Hwang JS (1992) Interference-free tool-path generation in the NC machining of parametric compound surfaces. Comput-Aided Des 24(12):667–676

Kim S-J, Yang M-Y (2006) A CL surface deformation approach for constant scallop height tool path generation from triangular mesh. Int J Adv Manuf Technol 28:314–320

Suresh K, Yang DCH (1994) Constant scallop-height machining of free-form surfaces. J Eng Ind 116(2):253–259

Yuwen S et al (2006) Iso-parametric tool path generation from triangular meshes for free-form surface machining. Int J Adv Manuf Technol 28(7):721–726

Yang DCH et al (2003) Boundary-conformed toolpath generation for trimmed free-form surfaces via Coons reparametrization. J Mater Process Tech 138(1–3):138–144

Park S, Choi BK (2000) Tool-path planning for directio-parallel area milling. Comput-Aided Des 32(1):17–25

Kim BH, Choi BK (2000) Guide surface based tool path generation in 3-axis milling: an extension of the guide plane method. Comput-Aided Des 32(3):191–199

Ding S et al (2003) Adaptive iso-planar tool path generation for machining of free-form surfaces. Comput-Aided Des 35(2):141–153

Lasemi A, Xue D, Gu P (2010) Recent development in CNC machining of freeform surfaces: a state-of-the-art review. Comput-Aided Des 42(7):641–654

Duncan JP, Mair SG (1983) Sculptured surfaces in engineering and medicine. Cambridge University Press, New York

Jun CS, Kim DS, Park S (2002) A new curve-based approach to polyhedral machining. Comput-Aided Des 34(5):379–389

Choi BK, Jun CS (1989) Ball-end cutter interference avoidance in NC machining of sculptured surfaces. Comput-Aided Des 21(6):371–378

Choi BK et al (1988) Compound surface modelling and machining. Comput-Aided Des 20(3):127–136

Choi BK, Km DH, Jerad RB (1997) C-space approach to tool-path generation for die and mold machining. Comput-Aided Des 29(9):657–669

Takeuchi Y et al (1989) Development of a personal CAD/CAM system for mold manufacture based on solid modeling techniques. Ann CIRP 38(1):429–432

Inui M (2003) Fast inverse offset computation using polygon rendering hardware. Computer-Aided Design 35(2):191–201

nVIDIA (2013) GPU accelerated research. http://www.nvidia.com/object/cuda_home.html. Accessed 25 Sept 2009

Hwu WM et al (2009) Compute unified device architecture application suitability. Comput Sci Eng 11:16–26

McMains S, Kardekar R, Burton G (2006) Finding feasible mold parting directions using graphics hardware. Comput-Aided Des 38(4):327–341

Gray PJ, Ismail F, Bedi S (2004) Graphics-assisted rolling ball method for 5-axis surface machining. Comput-Aided Des 36:653–663

Gray P, Ismail F, Bedi S (2004) Arc-intersect method for 5-axis tool positioning. Comput-Aided Des 37:663–674

Dokken T, Hagen TR, Hjelmervik JM (2005) The GPU as a high performance computational resource. Proceedings of the 21st spring conference on Computer graphics, 2005. p 21–26

Roth D, Ismail F, Bedi S (2005) Mechanistic modelling of the milling process using complex tool geometry. Int J Adv Manuf Technol 25(1):140–144

Roth D, Ismail F, Bedi S (2003) Mechanistic modeling of the milling process using an adaptive depth buffer. Comput-Aided Des 35:1287–1303

Inui M, Ohta A (2007) Using a GPU to accelerate die and mold fabrication. IEEE Comput Graph Appl 27:82–88

Carter JA, Tucker TM, Kurfess TR (2008) 3-Axis CNC path planning using depth buffer and fragment shader. Comput-Aided Des Appl 5(5):612–621

Stone SS et al (2008) Accelerating advanced MRI reconstructions on GPUs. J Parallel Distr Comp 68(10):1307–1318

Appel A (1968) Some techniques for shading machine renderings of solids. In Proceedings of the AFIPS Joint Computer Conferences. 1968. Atlantic City, New Jersey

Cook RL, Porter T, Carpenter L (1984) Distributed ray tracing. ACM SIGGRAPH Comput Graphics 18(3):137–147

Roth SD (1982) Ray casting for modeling solids. Comput Graph Image Process 18:109–144

Glassner (1995) Principles of digital image synthesis. Morgan Kaufman, San Francisco

Griffiths (1994) Toolpath Hilbert's curve 26(11):839–844

D Zhang, Bowyer A (1986) CSG set-theoretic solid modelling and NC machining of blend surfaces. In Proceedings of the second Annual Symposium on Computational Geometry. 1986. Yorktown Heights, New York

Jang D, Kim K, Jung J (2000) Voxel-based virtual multi-axis machining. Int J Adv Manuf Technol 16(10):709–713

Engle K et al (2006) Real-time volume graphics. A K Peters, Ltd., Wellesley

Chiou CJ, Lee YS (1999) A shape-generating approach for multi-axis machining G-buffer models. Comput-Aided Des 31(12):761–776

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tarbutton, J., Kurfess, T.R., Tucker, T. et al. Gouge-free voxel-based machining for parallel processors. Int J Adv Manuf Technol 69, 1941–1953 (2013). https://doi.org/10.1007/s00170-013-5148-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5148-x