Abstract

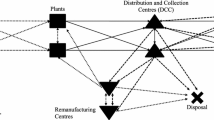

The design of a supply chain (SC) aims to minimize cost so the product can reach the customer at the cheapest cost with flexible demand. The demand of a product is variable with time and environment. Most of the researchers have considered investment cost, processing cost, and transportation cost as variable costs to minimize the cost while considering a constant demand. In actual practice, the demands are flexible. In this paper, a two-stage stochastic programming model has been proposed for a capacities-based network design of a supply chain for flexible demands while considering inventory carrying cost and missed opportunity cost in addition to the above-mentioned costs. It will enhance the logistic planning and seek the location network optimally. Furthermore, in the first stage, decision variables represent different nodes (facility locations of echelons) of the supply chain, with the assumption that they will be considered at the design stage before uncertain parameters are unveiled. On the other hand, decision variables related to the amount of products to be produced and stored in the nodes of the SC, the flows of materials among the entities of the network, and shortfalls and excess at the customer centers are considered as second-stage variables. The methodology has been illustrated by solving an example. It was found that the proposed model yields more feasible and advantageous results.

Similar content being viewed by others

References

Alonso-Ayuso A, Escudero LF, Garin A, Ortuno MT, Perez G (2003) An approach for strategic supply chain planning under uncertainty based on stochastic 0–1 programming. J Glob Optim 26:97–124

Altiparmak F, Gen M, Lin L, Paksoy T (2006) A genetic algorithm approach for multiobjective optimization of supply chain networks. Comput Ind Eng 51:197–216

Amiri A (2006) Designing a distribution network in a supply chain system: formulation and efficient solution procedure. Eur J Oper Res 171:567–576

Chopra S, Meindl P, Kalra DV (2006) Supply chain management: strategy, planning and operations, 3rd edn. Pearson education, Inc., New Jersey

Cohen M, Lee H (1988) Strategic analysis of integrated production– distribution systems: models and methods. Oper Res 36(2):216–228

Daskin M, Coullard C, Shen ZJ (2002) An inventory-location model: formulation, solution algorithm and computational results. Ann Oper Res 110:83–106

Du F, Evans GW (2008) A bi-objective reverse logistics network analysis for post-sale service. Comput Oper Res 35:2617–2634

Eppen GD, Martin RK, Schrage L (1989) A scenario approach to capacity planning. Oper Res 37(4):517–524

Geoffrion A (1976) Better distribution planning with computer models. Harvard Business Review (July–August):92–99

Gupta A, Maranas CD (2003) Managing demand uncertainty in supply chain planning. Comput Chem Eng 27:1219–1227

Gupta A, Maranas CD, McDonald CM (2000) Mid-term supply chain planning under demand uncertainty: customer demand satisfaction and inventory management. Comput Chem Eng 24:2613–2621

Iassinovski S, Artiba A, Bachelet V, Riane F (2003) Integration of simulation and optimization for solving complex decision making problems. Int J Prod Econ 85(1):3–10

Jayaraman V, Patterson RA, Rolland E (2003) The design of reverse distribution networks: models and solution procedures. Eur J Oper Res 150:128–149

Jayaraman V, Ross A (2003) A simulated annealing methodology to distribution network design and management. Eur J Oper Res 144:629–645

Klibi W, Lasalle F, Martel A, Ichoua S (2010) The stochastic multi-period location transportation problem. Transp Sci 44–2:221–237

Lee D, Dong M (2008) A heuristic approach to logistics network design for end-of lease computer products recovery. Transp Sci 44:455–474

Melo MT, Nickel S, Saldanha-da-Gama F (2009) Facility location and supply chain management—a review. Eur J Oper Res 196:401–412

Min H, Ko HJ (2008) The dynamic design of a reverse logistics network from the perspective of third-party logistics service providers. Int J Prod Econ 113:176–192

MirHassani SA, Lucas C, Mitra G, Messina E, Poojari CA (2000) Computational solution of capacity planning models under uncertainty. Parallel Comput 26:511–538

Petkov SB, Maranas CD (1997) Multiperiod planning and scheduling of multipurpose batch plants under demand uncertainty. Ind Eng Chem Res 36:4864–4881

Pishvaee MS, Farahani RZ, Dullaert W (2010) A memetic algorithm for bi-objective integrated forward/reverse logistics network design. Comput Oper Res 37:1100–1112

Pishvaee MS, Kianfar K, Karimi B (2010) Reverse logistics network design using simulated annealing. Int J Adv Manuf Technol 47:269–281

Santoso T, Ahmed S, Goetschalckx M, Shapiro A (2005) A stochastic programming approach for supply chain network design under uncertainty. Eur J Oper Res 167:96–115

Shen ZJ, Daskin M (2005) Trade-offs between customer service and cost in integrated supply chain design. Manuf Serv Oper Manag 7:188–207

Shen ZJ (2007) Integrated supply chain design models: a survey and future research directions. J Ind Manag Optim 3(1):1–27

Shu J, Teo CP, Shen ZJ (2004) Stochastic transportation-inventory network design problem. Oper Res 53:48–60

Sodhi M (2003) How to do strategic supply chain planning. Sloan Manag Rev 45(1):69–75

Sung CS, Song SH (2003) Integrated service network design for a cross-docking supply chain network. J Oper Res Soc 54:1283–1295

Timpe CH, Kallrath J (2000) Optimal planning in large multi-site production networks. Eur J Oper Res 126:422–435

Tsiakis P, Shah N, Pantelides CC (2001) Design of multiechelon supply chain networks under demand uncertainty. Ind Eng Chem Res 40(16):3585–3604

Yeh W-C (2005) A hybrid heuristic algorithm for the multistage supply chain network problem. Int J Adv Manuf Technol 26:675–85

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, A.R., Jain, R. & Mishra, P.K. Capacities-based supply chain network design considering demand uncertainty using two-stage stochastic programming. Int J Adv Manuf Technol 69, 555–562 (2013). https://doi.org/10.1007/s00170-013-5054-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5054-2