Abstract

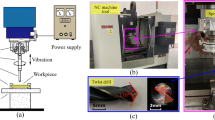

Natural diamond tool is quickly worn out while cutting a workpiece made of a tungsten-based alloy. This paper presents a new approach to reduce tool wear: ultrasonic vibration cutting of a workpiece made of a tungsten-based alloy based on gas–liquid atomization cooling. An atomizer is a device which mixes carbon dioxide gas with vegetable oil and changes the liquid into minute droplets, which are carried by a stream of gas. Atomizer is also a device that incorporates a venture device to translate liquid into a gas stream. The atomized minute droplets act as the cooling and lubricating medium to protect the tools. The system is designed to ensure that droplets can spread all over the surface of a work piece. At a constant spindle speed, feed rate, and cutting depth, the experiments were carried out for investigating the effects of the tool vibration parameters, carbon tetrachloride liquid flow rate, carbon dioxide gas flow, and gas–liquid mass ratio on the tool wear. The experiments showed that the technology of ultrasonic vibration with gas–liquid atomization cooling effectively prolongs the tool life in cutting tungsten-based alloy.

Similar content being viewed by others

References

Chen J, Liu M, Chi Y, Liu Y, Shan D (2008) Research on the tool wear and finishing size precision in ultrasonically assisted turning W-based alloys. Mach Tool Hydr 36(8):44–46

Jiten Dasa G, Appa Raoa SK, Pabib MS, Sarmaa B (2011) Deformation behaviour of a newer tungsten heavy alloy. Mater Sci Eng A 528(19–20):6235–6247

Ye Y, Ye W (2006) Machining of tungsten alloy. World Manuf Eng Market 4:89–90

Suzuki N, Haritani M, Yang J, Hino R, Shamoto E (2007) Elliptical vibration cutting of tungsten alloy molds for optical glass parts. Ann CIRP 56(1):127–130

Nath C, Rahman M, Neo KS (2009) A study on the effect of tool nose radius in ultrasonic elliptical vibration cutting of tungsten carbide. J Mater Proc Tech 209(17):5830–5836

Suzuki N, Yan Z, Haritani M, Yang J-b, Hamada S, Hino R, Shamoto E (2007) Ultraprecision machining of tungsten alloy by applying ultrasonic elliptical vibration cutting. J Japan Soc Prec Eng 73(3):360–366

Rongdi H, Junyan L, Yongfeng S (2007) Research on experimentation of green turning with water vapor as coolant and lubricant. Ind Lubr Tribol 57(5):187–192

Moriwari et al (1991) Ultra-precision diamond cutting of stainless steel by applying ultrasonic vibration. Annals of the CIRP 40(1):559–562

Polini W, Turchetta (2005) Evaluation of diamond tool wear. Int J Adv Manuf Technol 26(9–10):959–964

Xiaobin C, Jun Z, Xianhua T (2013) Cutting forces, chip formation, and tool wear in high-speed face milling of AISI H13 steel with CBN tools. Int J Adv Manuf Technol 64(9–12):1737–1749

Babitskya VI, Kalashnikovb AN, Meadowsa A, Wijesundara AAHP (2003) Ultrasonically assisted turning of aviation materials. J Mater Process Technol 132(1–3):157–167

Takeyama H, Lijima N (1998) Machinability of glass fiber reinforced plastics and application of ultrasonic machining. Ann CIPR 37(1):93–96

Kim J-D, Choi I-H (1998) Characteristics of chip generation by ultrasonic vibration cutting with extremely low cutting velocity. Int J Adv Manuf Technol 14(1):2–6

Mordyuk BN, Prokopenko GI et al (2006) Fatigue life improvement of α-titanium by novel ultrasonically assisted technique. Mater Sci Eng A 437:396–405

Brinksmeier E, Gläbe R, Osmer J (2006) Ultra-precision diamond turning of steel molds. CIRP Ann Manuf Technol 55:551–554

Nath C, Rahman M (2008) Effect of machining parameters in ultrasonic vibration turning. Int J Mach Tool Manuf 48:965–974

Gan J, Wang X, Zhou M, Ngoi B, Zhong Z (2003) Ultraprecision diamond turning of glass with ultrasonic vibration. Int J Adv Manuf Tech 21(12):952–955

Zhimin Z, Yuanliang Z, Jian D, Li XY (2009) Effect of cutting parameters on diamond tool life during cutting stainless steel. Mater Sci Forum 626–627:105–110

Liu K, Li XP, Rahman M (2008) Characteristics of ultrasonic vibration-assisted ductile mode cutting of tungsten carbide. Int J Adv Manuf Technol 35(7–8):833–841

Shen XH, Zhang JH, Xing DLX, Zhao YF (2012) A study of surface roughness variation in ultrasonic vibration-assisted milling. Int J Adv Manuf Technol 58(5–8):553–561

Afazov SM, Ratchev SM, Segal J (2012) Prediction and experimental validation of micro-milling cutting forces of AISI H13 steel at hardness between 35 and 60 HRC. Int J Adv Manuf Technol 62(9–12):887–899

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhou, Z., Lv, Y. et al. Wear behavior of natural diamond tool in cutting tungsten-based alloy. Int J Adv Manuf Technol 69, 329–335 (2013). https://doi.org/10.1007/s00170-013-5045-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5045-3