Abstract

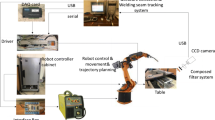

Automatic welding technology is a solution to increase welding productivity and improve welding quality, especially in thick plate welding. In order to obtain high-quality multi-pass welds, it is necessary to maintain a stable welding bead in each pass. In the multi-pass welding, it is difficult to obtain a stable weld bead by using a traditional teaching and playback arc welding robot. To overcome these traditional limitations, an automatic welding tracking system of arc welding robot is proposed for multi-pass welding. The developed system includes an image acquisition module, an image processing module, a tracking control unit, and their software interfaces. The vision sensor, which includes a CCD camera, is mounted on the welding torch. In order to minimize the inevitable misalignment between the center line of welding seam and the welding torch for each welding pass, a robust algorithm of welding image processing is proposed, which was proved to be suitable for the root pass, filling passes, and the cap passes. In order to accurately track the welding seam, a Fuzzy-P controller is designed to control the arc welding robot to adjust the torch. The Microsoft Visual C++6.0 software is used to develop the application programs and user interface. The welding experiments are carried out to verify the validity of the multi-pass welding tracking system.

Similar content being viewed by others

References

Kim YB, Kim JG, Jang WT, Park J, Moon HS, Kim JO (2008) Development of automatic welding system for multi-layer and multi-pass welding. Proceedings of the 17th World Congress The International Federation of Automatic Control Seoul, Korea, July 6–11, 2008 pp: 4290–4291

Kang MG, Kim JH, Park YJ, Woo GJ (2007) Laser vision system for automatic seam tracking of stainless steel pipe welding machine. International Conference on Control, Automation and System, Seoul, Korea pp: 1046–1051

Haug K, Pritschow G (1998). Robust laser-stripe sensor for automated weld seam tracking in the shipbuilding industry. IECON ‘98. Proceedings of the 24th Annual Conference of the IEEE Industrial Electronics Society (Cat. No.98CH36200) 2: 1236–1241

Kuo HC, Wu LJ (2002) An image tracking system for welded seams using fuzzy logic. J Mater Process Technol 120:169–185

Huang YW, Tung PC, Wu CY (2007) Tuning PID control of an automatic arc welding system using a SMAW process. Int J Adv Manuf Technol 34:56–61

Moon HS, Kim YB, Beattie RB (2006) Multi sensor data fusion for improving performance and reliability of fully automatic welding system. Int J Adv Manuf Technol 28:286–293

Bae KY, Park JH (2006) A study on development of inductive sensor for automatic weld seam tracking. J Mater Process Technol 176:111–116

Bingul Z, Cook GE, Strauss AM (2000) Application of fuzzy logic to spatial thermal control in fusion welding. IEEE Trans Ind Appl 36(6):1523–1530

Pritschow G, Mueller G, Horber H (2002) Fast and robust image processing for laser stripe-sensors in arc welding automation. Proc IEEE Int Symp Ind Electron 2:651–656

Zhou L, Lin T, Chen SB (2006) Autonomous acquisition of seam coordinate for arc welding robot based on visual servoing. J Intell Robot Syst 47:239–255

Chokkalingham S, Chandrasekhar N, Vasudevan M (2011) Predicting the depth of penetration and weld bead width from the infra red thermal image of the weld pool using artificial neural network modeling. J Intell Manuf 385–392

Sung K, Lee H, Choi YS (2009) Development of a multiline laser vision sensor for joint tracking in welding. Weld J 88(4):79–85

Villán AF, Acevedo RG, Alvarez EA, Lopez AC, Garcia DF, Fernandez RU, Meana MJ (2011) Low-cost system for weld tracking based on artificial vision. Ind Res 47(3):1159–1167

Kim JW, Bae HS (2005) A study on a vision sensor system for tracking the I-butt weld joints. J Mech Sci Technol 19(10):1856–1863

Fang ZJ, Xu D, Tan M (2010) Visual seam tracking system for butt weld of thin plate. Int J Adv Manuf Technol 49:519–526

Xu PQ, Tang XH, Yao S (2008) Application of circular laser vision sensor (CLVS) on welded seam tracking. J Mater Process Technol 205:404–410

Chen W (1990) Monitoring joint penetration using infrared sensing techniques. Weld J 69(5):181–185

Huang W, Kovacevic R (2012) Development of a real-time laser-based machine vision system to monitor and control welding process. Int J Adv Manuf Technol 63:235–248

Mark S. Nixon, Alberto S. Aguado (2010) Feature extraction and image processing. Newnes, Oxford pp.10-11

Zhang TY, Suen CY (1984) A fast parallel algorithm for thinning digital patterns. Commun ACM 27(3):236–239

Yu JY, Na SJ (1998) A study on vision sensors for seam tracking of height-varying weldment. Part 2: applications. Mechatronics 8:21–36

Shi YH, Wang GR (2006) Vision-based seam tracking system for underwater flux cored arc welding. Sci Technol Weld Join 11(3):271–277

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, W.P., Xiong, Z.Y. & Wan, W. Autonomous seam acquisition and tracking system for multi-pass welding based on vision sensor. Int J Adv Manuf Technol 69, 451–460 (2013). https://doi.org/10.1007/s00170-013-5034-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5034-6