Abstract

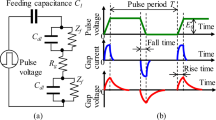

This paper presents the research and development of a new electrochemical machining technique, electrochemical turning (ECT), which can produce parts with complex shapes. In this technique, the electrolyte passes through a tubular electrode and is pumped to the workpiece. The actual dissolution is measured by using a new type of gap measuring and control sensor. In this sensor, the electrolyte between the tool and the workpiece becomes a resistance of a bridge circuit, while three other resistances are constant. Hence, if the gap size changes, the resistance of the electrolyte and consequently the voltage of the bridge change. This voltage can be used for measuring and control the gap size. Keeping the gap size in a constant value enables the machine to compare the actual and desired dimensions. A suitable ECT setup primarily consists of various components and subsystems, e.g., a mechanical machining unit, an electrical power and controlling system, an electrolyte flow system, etc. Some experiments were performed to identify the effects of voltage, gap size, and time on the material removal rate. As can be predicted, the removal rate increased with voltage and time and decreased with gap size. Also, surface roughness increased with voltage. More attempts will generate more possible applications for ECT.

Similar content being viewed by others

References

Hassan El-Hofy (2005) Advanced machining Processes, McGraw-Hill

Rajurkar KP, Zhu D, McGeough JA, Kozak J et al (1999) New development in electrochemical machining. Ann CIRP 48:567–579

McGeough JA (1974) Principles of electrochemical machining. Chapman and Hall, London

Bhattacharyya B, Munda J, Malapati M (2004) Advancement in electrochemical micromachining. Int J Mach Tools Manuf 44:1577–1589

Choi I-H, Kim J-D (1998) A study of the characteristics of the electrochemical deburring of a governor-shaft cross hole. J Mater Process Technol 75:198–203

Paulo Davim J (2008) Machining Fundamentals and Recent Advances. springer

Chryssolouris G, Wallowitz M (1984) Electrochemical hole making. Ann CIRP 33:99–103

Mohan S, Shan HS (2005) A review of electrochemical macro to microhole drilling processes. Int J Mach Tools Manuf 45:137–152

Hopenfeld J, Cole RR (1969) Prediction of the one-dimensional equilibrium cutting gap in electrochemical machining. Trans Of ASME J Eng Ind B8:755–765

Bejar MA, Gutierrez F (1993) On the determination of current efficiency in electrochemical machining with a variable gap. J Mater Process Technol 37:691–699

Thorpe JF, Zerkle RD (1969) Analytic determination of the equilibrium gap in electrochemical machining. Int J Mach Tool Manuf 9:131–144

Clifton D, Mount AR, Alde GM, Jardine D (2002) Ultrasonic measurement of the interelectrode gap in electrochemical machining. International Journal of Machine Tools & Manufacture 42:1259–1267

Hocheng H, Pa PS (2002) The application of turning tool as the electrode in electropolishing. J Mater Process Technol 120:6–12

Taweel TAE (2008) Modeling and analysis of hybrid electrochemical turning-magnetic abrasive finishing of 6061 Al/Al2O3 composite. Int J Adv Manuf Technol 37:705–714

Ebeid SJ, Taweel TAE Surface improvement through hybridization of electrochemical turning and roller burnishing based on the Taguchi technique. Proceedings of the Institution of Mechanical Engineers, Part B: J Eng Manuf 219 (5):423–430

Kang M, Yang Y, Fu XQ (2009) Study on numerical-controlled electrochemical turning. Adv Mater Manuf Sci Technol 13(1):351–356

Borrie JA (1986) Modern control systems. Prentice Hall International, UK

Bilgi DS, Kumar R, Jain VK, Shekhar R (2008) Predicting radial overcut in deep holes drilled by shaped tube electrochemical machining. Int J Adv Manuf Technol 39:47–54

Natsu W, Ikeda T, Kunieda M (2007) Generating complicated surface with electrolyte jet machining. Precis Eng 31:33–39

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yahyavi Zanjani, M., Ghattan Kashani, H. & Mirahmadi, A. Improvement of electrochemical turning for machining complex shapes using a simple gap size sensor and a tubular shape tool. Int J Adv Manuf Technol 69, 375–381 (2013). https://doi.org/10.1007/s00170-013-5029-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5029-3