Abstract

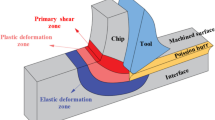

Burr is an important character of the surface quality for machined parts, and it is even more severe in micro cutting. Due to the uncut chip thickness and the cutting edge radius at the same range in micro cutting process, the tool extrudes the workpiece with negative rake angle. The workpiece flows along the direction of minimum resistance, and Poisson burr is formed. Based on the deformation analysis and experiment observations of micro cutting process, the factor for Poisson burr formation is analyzed. It is demonstrated that the ratio of the uncut chip thickness to the cutting edge radius plays an important role on the height of Poisson burr. Increasing the uncut chip thickness or decreasing the cutting edge radius makes the height of exit burr reduce. A new model of micro exit burr is established in this paper. Due to the size effect of specific cutting energy, the exit burr height increases. The minimum exit burr height will be obtained when the ratio of uncut the chip thickness to the cutting edge radius reaches 1. It is found that the curled radius of the exit burr plays an important role on the burr height.

Similar content being viewed by others

References

Fang FZ, Wu H, Liu XD, Liu YC, Ng ST (2003) Tool geometry study in micromachining. J Micro Mech Micro Eng 13:726–731

Chen MJ, Ni HB, Wang ZJ, Jiang Y (2012) Research on the modeling of burr formation process in micro-ball end milling operation on Ti–6Al–4V. Int J Adv Manuf Technol 62(9–12):901–912

Thepsonthi T, Özel T (2012) Multi-objective process optimization for micro-end milling of Ti-6Al-4V titanium alloy. Int J Adv Manuf Technol 63(9–12):903–914

Masuzawa T (2000) State of the art of micromachining. CIRP Ann-Manuf Techn 49(2):473–488

Mian AJ, Driver N, Mativenga PT (2010) A comparative study of material phase effects on micro-machinability of multiphase materials. Int J Adv Manuf Technol 50(1–4):163–174

Nakayamaa K, Arai M (1987) Burr formation in metal cutting. CIRP Ann-Manuf Techn 36(1):33–36

Bissacco G, Hansen HN, Chiffre LD (2005) Micromilling of hardened tool steel for mould making applications. J Mater Process Tech 167(2–3):201–207

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33(4):402–407

Aurich JC, Dornfeld D, Arrazola PJ, Frankea V, Leitza L, Min S (2009) Burrs—analysis, control and removal. CIRP Ann-Manuf Techn 58(2):519–542

Lee K, Dornfeld DA (2005) Micro-burr formation and minimization through process control. Precis Eng 29(2):246–252

Gillespie K, Blotter PT (1976) The formation and properties of machining burrs. Trans ASME J Eng Ind 98(1):66–74

Ducobu F, Rivière-Lorphèvreb E, Filippi E (2011) A Lagrangian FEM model to produce saw-toothed macro-chip and to study the depth of cut influence on its formation in orthogonal cutting of Ti6Al4V. Adv Mate Res 223:3–11

Qu HJ, Yang JH, Wang GC (2012) Simulation and control of two side direction burr. App Mech Mater 143–144:428–432

Hashimura M, Hassamamontr J, Dornfeld DA (1999) Effect of in plane exit angle and rake angles on burr height and thickness in face milling operation. Trans ASME J Manuf Sci Eng 121(1):13–19

Deng WJ, Xia W, Tang Y (2009) Finite element simulation for burr formation near the exit of orthogonal cutting. Int J Adv Manuf Technol 43(9–10):1035–1045

Ng CK, Melkote SN, Rahman M, Kumar AS (2006) Experimental study of micro- and nano-scale cutting of aluminum 7075-T6. Int J Mach Tool Manuf 46(9):929–936

Wu J, Liu Z (2010) Modeling of flow stress in orthogonal micro-cutting process based on strain gradient plasticity theory. Int J Adv Manuf Technol 46(1–4):859–870

Simoneau A, Ng E, Elbestawi MA (2006) Modeling the effects of microstructure in metal cutting. Int J Mach Tool Manuf 47(2):368–375

Mian AJ, Driver N, Mativenga PT (2011) Identification of factors that dominate size effect in micro-machining. Int J Mach Tool Manuf 51(5):383–394

Wyen C, Jaeger D, Wegener K (2012) Influence of cutting edge radius on surface integrity and burr formation in milling titanium. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4507-3

Li P, Oosterling JAJ, Hoogstrate M, Langen HH, Schmidt RHM (2011) Design of micro square endmills for hard milling applications. Int J Adv Manuf Technol 57(9–12):859–870

Schueler GM, Engmann J, Marx T, Haberland R, Aurich JC (2010) Burr formation and surface characteristics in micro-end milling of titanium alloys. Burrs-Analysis Control and Removal 4:129–138

Niknam SA, Songmene V (2012) Modeling of burr thickness in milling of ductile materials. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4479-3

Ding H, Chen SJ, Ibrahim R, Cheng K (2011) Investigation of the size effect on burr formation in two-dimensional vibration-assisted micro end milling. P I Mech Eng B-J Eng 225(11):2032–2039

Ko S, Dornfeld DA (1996) Analysis of fracture in burr formation at the exit stage of metal cutting. J Mater Process Tech 58(2–3):189–200

Lekkala R, Bajpai V, Singh RK, Joshi SS (2011) Characterization and modeling of burr formation in micro-end milling. Precis Eng 35(4):625–637

Wyen CF, Wegener K (2010) Influence of cutting edge radius on cutting forces in machining titanium. CIRP Ann-Manuf Techn 59(1):93–96

Lai X, Li H, Li C, Lin Z, Ni J (2008) Modeling and analysis of micro scale milling considering size effect, micro cutter edge radius and minimum chip thickness. Int J Mach Tool Manuf 48(1):1–14

Ko S, Dornfeld DA (1991) A study on burr formation mechanism. J Eng Mater Technol 113(1):75–87

Toropov AA, Ko SL, Lee JM (2006) A new burr formation model for orthogonal cutting of ductile materials. CIRP Ann-Manuf Techn 26(1):55–58

Tamaniau DA, Dautzenberg JH (1991) Bluntness of the tool and process forces in high-precision machining. CIRP Ann-Manuf Techn 40(1):65–68

Rao S, Shunmugam MS (2012) Analytical modeling of micro end-milling forces with edge radius and material strengthening effects. Mach Sci Technol 16(2):205–227

Nedelß C, Hintze W, Luttervelt CAV (1989) Characteristic parameters of chip control in turning operations with indexable inserts and three-dimensionally shaped chip formers. CIRP Ann-Manuf Techn 38(1):75–79

Ohbuchia Y, Obikawa T (2005) Adiabatic shear in chip formation with negative rake angle. Int J Mech Sci 47(9):1377–1392

Worthington B, Redford AH (1973) Chip curl and the action of the groove type chip former. Int J Mach Tool Des Res 13(4):257–270

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, T., Liu, Z. & Xu, C. Influence of size effect on burr formation in micro cutting. Int J Adv Manuf Technol 68, 1911–1917 (2013). https://doi.org/10.1007/s00170-013-4801-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-4801-8